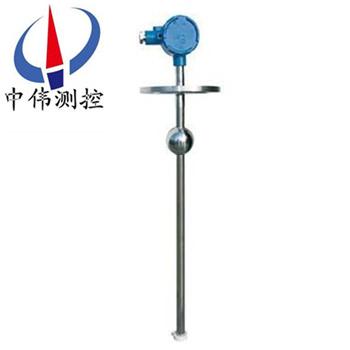

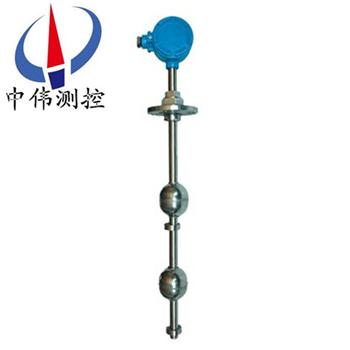

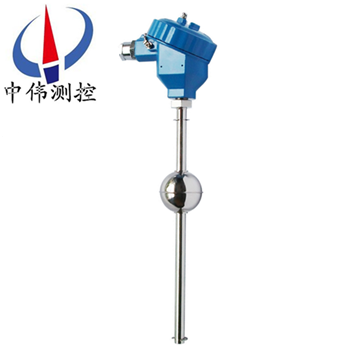

Explosion-proof connecting rod ball float liquid level switch

Products overview:

ZW - UQK80 seriesExplosion-proof connecting rod ball float liquid level switchAnd small ball float liquid level switch principle basic same, usually will seal nonmagnetic metal or plastic tube magnetic reed switch according to the need to set up one or more points, more of a ring magnet inside the hollow and floating ball is fixed on the magnetic reed switch related position in stem diameter, the floating ball to fluctuate within a certain scope, using the floating ball in the magnet to attract the magnetic reed switch is closed, the switch action, to control the liquid level.

Second, the working principle:

ZW - UQK80 series explosion-proof connecting rod ball float liquid level switch used magnetic operation without mechanical fittings simple operation and reliable when measured medium float float float switch float drives the moving subjects will float at the other end of the magnet at the same time control switch on the action bar magnets.

In airtight metal or plastic tube magnetic reed switch set one or more points and then through one or more of the hollow pipe and the internal floating ball with ring magnets and using fixed loop control floating ball and magnetic reed switch in the relevant position on the floating ball within a certain range floating up and down using the floating ball in the magnet to attract the magnetic reed switch contacts open and close action.

Applications:

ZW - UQK80 series explosion-proof connecting rod ball float liquid level switch is by the isolation of a floating ball and micro switch group 2.Ball float liquid level switch is widely used in electronics, electric power, chemical industry, water treatment, water supply and drainage and other liquid level control and alarm from all walks of life.With self-monitoring ball float liquid level switch can be easily at any time to switch and the system self test, to ensure that the switch and the safe operation of the system.

Four, the main features:

1, can make multipoint control control switch position can be according to user needs custom-made;

2, the use of magnetic reed switch does not need to supply the power contact life can reach 2 million times;

3, all of the switch wire in the same terminal block external construction wiring cost is low;

4, more than other forms of liquid level switch, switch control points and compare the unit price of RF type zui low;

5, junction box of the protection grade is above the IP - 65;

6, have PPSUS316 metal material therefore regardless of acid, alkali, solvent or all kinds of fuel oil is suitable products can be used;

7, magnetic reed switch and the wires and liquid separation so completely used in high temperature and high pressure equipment can also be security;

8, suit is suitable for high temperature and high pressure;

9 magnetic reed switch, dry 60 va contact through float installation location choice normally open or normally closed;

10, 316 SS float tube and installation interface is suitable for bad environment;

11, facilitate electrical on the base of the regulation that can rotate in American standard NEMA 4 x polypropylene casing;

12, customizable catheter length and switch set point size.

Five, the technical parameters:

1, the working temperature: standard: - 40 ~ 150 ℃;

Medium temperature type: - 40 ~ 250 ℃;

High temperature type: - 40 ~ 350 ℃;

2, environmental temperature: - 40 ~ 70 ℃;

3, working pressure: 0.1 ~ 6.3 MPa.

4, medium density: acuity 0.45 g/cm3.

5, the output signal: SPDT relay (single pole double throw);

6, contact capacity: 250 vac 7 a.

7, switch life: 5 x l04 times;

8, electrical interface: M20 thread in x 1.5;

9, explosion-proof grade: flameproof Exd Ⅱ BT4;The Ann model Exia Ⅱ CT1 ~ T6.

10, protection level: IP65;

11, process connection: HG20592 ~ 20635-97 (above, other flange standards when ordering user, please indicate;

12, liquid material: stainless steel;

13, junction box material: aluminum alloy.

Six, installation instructions:

1, the installation position should be far away from the water inlet, otherwise will switch the misoperation caused by fluctuations in water inlet.

2, if the switch device in the vessel wall, L type Angle bracket can be mounted to the system.

3, if the switchgear in mixing zone, can be installed or wave wave tube platens.

4, choose pipe diameter greater than the float of the diameter of the flange connecting pipe.

More than 5, wiring advice use core cable.

6, the control circuit load must match the float switch contact capacity.

7, the proportion of liquid to be tested must be greater than the proportion of floating ball.

8, the action point floating ball is already in the factory according to customer orders to adjust, please don't adjust floating ball position.

Seven, contact protection circuit:

1, when the float switch used in motor, relay, solenoid coil of inductive load circuit, such as advice on both ends of the load in parallel circuit protection such as RC (buffer), resistor, diode, etc.

Note: do not use the float switch connected directly to the electromagnetic valve, the motor or electromagnetic switch

2, when the float switch used in capacitor, incandescent light bulbs, there is a long cable capacitive load, such as between switch contact will produce a surge current;Advice on both ends of float switch protection circuit in parallel, such as a current limiting resistor or surge absorber, etc.

Eight, wiring and contact details:

1, open the box, the cable from the line wear into the mouth, and lock into the line cable fixed head, according to the nameplate and patch panel terminals on the logo will be on contact wire connected to the corresponding terminal.

2, patch panel terminal stage identification Numbers from small to large from top to bottom corresponds to the floating ball contact.

3, the floating ball contacts are divided into three types:

1 1 A: said level higher than the float A - C contact through

(2) 1 B: it means the level below the float B - C contact through

(3) 1 ab: it means the level below the float A - C contact disconnect, B - C connected;Liquid level is higher than the float is A - C contact through, B - C disconnect

4, after the completion of the connection will be lifted the lid, please tighten and wiring fixed, in order to ensure waterproof connector.

Nine, common failures and troubleshooting

1, the failure phenomenon, cause analysis and elimination method

Floating ball is not action

(1) the proportion of liquid is less than the proportion of floating ball - that the proportion of floating ball

(2) ball float water to replace the floating ball with the company

(3) foreign body removal stuck float -

2, floating ball movement, but no signal output

Floating ball position offset to adjust the floating ball position.

Ten, notable matters of installation:

1, wiring core cable is recommended to use more control circuit load must match and float switch contact capacity;

2, the installation position should be far away from the inlet or switch will misoperation caused by fluctuations in water inlet;

3, if the switch device in the container can be mounted to the wall L type Angle bracket;

4, when the float switch used in motor relay solenoid coil of inductive load such as advice on both ends of the load in parallel circuit protection circuit, such as RC (buffer) rheostat diode, etc.;

5, after the completion of the connection will be lifted the lid, please tighten and wiring mouth fixed to ensure waterproof junction box;

6, patch panel terminal stage identification Numbers from small to large from top to bottom corresponds to the floating ball contact.

Eleven, selection of coding:

Factory standard | Registration type | Code instructions | ||||||||

ZW- | UQK80 | In ordinary connecting rod ball float liquid level switch (wei measurement and control) | ||||||||

ZW- | UQKS80 | With self-check type connecting rod ball float liquid level switch | ||||||||

Code name | Basic types of | S: stainless steel3044;316;The temperature: - 30~120℃;pressure:≤2.5Mp。 F: polypropylenePP ;The temperature: - 30~80℃;Pressure:Or less0.4Mpa P: ptfePTFE ;The temperature: - 30~160℃;pressure:≤1.0Mpa | ||||||||

S | standard | |||||||||

F | Anti-corrosion type | |||||||||

P | The corrosion type | |||||||||

Code name | Process connection | |||||||||

A | The flangeDN50 | |||||||||

B | The flangeDN80 | |||||||||

C | The flangeDN100 | |||||||||

D | External threadG2(The corrosion type, not with the specifications) | |||||||||

Code name | The control points | |||||||||

1 | 1A control switch,1A floating ball | |||||||||

2 | 2A control switch,2A floating ball | |||||||||

3 | 3A control switch,3A floating ball | |||||||||

4 | 4A control switch,4A floating ball | |||||||||

N | NA control switch,NA floating ball | |||||||||

Code name | Answer the liquid material | |||||||||

B | 1Cr18Ni9Ti、321 | |||||||||

S | 304SS | |||||||||

L | 316L | |||||||||

P | PP、PPR | |||||||||

F | PTFE | |||||||||

C | PVC | |||||||||

Code name | Optional item | |||||||||

D | flameproof ExdIICT2~T6 | |||||||||

E | The Ann model ExizCT2~T6 | |||||||||

C | With the converter (a convertible two control points) | |||||||||

F | With isolation security gate | |||||||||

Code name | The installation height | |||||||||

- | L1mm,Under the lower limit, fell through | |||||||||

- | L2mm,The lower limit,Fall through | |||||||||

- | L3mm,ceiling,Up through | |||||||||

- | L4mm,On the ceiling,Up through | |||||||||

- | LNmm,L connected or fall through | |||||||||

Code name | Medium density | |||||||||

- | (kg/m3) | |||||||||

Code name | The rated pressure | |||||||||

D | Atmospheric pressure | |||||||||

Note: please specify your connection mode, the process of the size and action point location.

Twelve, design selection and ordering information:

1, liquid level control device specifications;

2, measurement range;

3, working pressure, and temperature;

4, control device for material;

5, special requirements;

6, whether level device matching supply vessel flange, bolts, nuts, valves and fittings such as sealing washer, so that the correct selection.

After-sales service commitment:

Liquid level switch 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.