Single room balance container

Products overview:

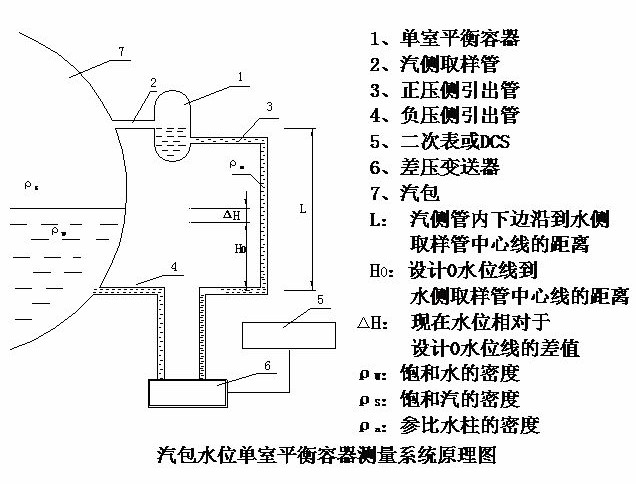

ZW - EP seriesSingle room balance containerMainly includes the following several parts: balance container, positive pressure measurement sampling tube, suction side side sampling tube, the second table, DCS devices and related parts.

Second, the working principle:

ZW - EP series single room balance container main measurement principle is the use of positive pressure and negative pressure measuring side formed by the differential signal to the transmitter, the transmitter signal to DCS in calculation of the public to realize water level measurement.

Balance container and differential pressure transmitter, to monitor the drum water level, and external changes the output level of the differential signal, differential pressure transmitter and the differential signal is converted into electrical signals into the DCS system or other display instrument or control equipment, can only reflect the normal operation of the boiler steam drum water level within the measurement.

Applications:

ZW - EP series single room balance container with water level indicator or differential pressure transmitter, can be in normal operation of boiler and, in the process of the furnace and circumstances, to monitor the drum water level, and external changes the output level of differential pressure (AP) signal, guarantee the safe operation of the boiler.

Four, product structure:

1, single room balance containers by condensation, equal tee, elbow, etc;

2, condensing vessels by cylinder, head of welding and become, girth weld by 100%.

Five, the main features:

Advantages:

1 measurement deviation is small

2 signal stability, followed in a timely manner, timely feedback real within the drum water level

3 long service life.

Disadvantages:

1 are greatly influenced by the environment, than the water temperature is not uniform, not real-time quantitative calibration.

2 in winter and summer, light during the day, had a greater influence on the environment such as wind.

Only guarantee 3 reference water column temperature constant, can achieve balance container measure effect.

Six, product model and use scope:

type No. | The name According to | Using range |

ZW-EP-6.4A | Single-layer balancer | pressure≤6.4MPa |

ZW-EP-20A | Single-layer balancer | pressure≤20.0MPa |

ZW-EP-32A | Single-layer balancer | pressure≤32.0MPa |

ZW-EP-6.4B | Double balancer | pressure≤6.4MPa |

ZW-EP-25B | Double balancer | pressure≤25.0MPa |

Seven, debugging steps:

1. The system doesn't work (boiler drum level is zero) : on the premise of ensure the pressure chamber full of condensed water, close the balance valve and open the valve, plus or minus phase balance container valve of liquid at the same time open the double room. The output should be to 20 ma, and full scale. The output will be dispatched to 4 ma, and the negative transfer of zero to 100% range.

2. The system is working (steam boiler liquid level) : on the premise of ensure the pressure chamber full of condensed water, close the balance valve and open the valve, plus or minus phase balance container valve of liquid at the same time close double room.

3. Measurement system normal work, three sets of valve status: balancing valve closed;The positive and negative phase valve opens. Double room open valve of liquid balance container.

Eight, notable matters of installation:

1, the boiler steam drum center distance of steam pipe should be the same as the balance container;

2, balance the pressure vessel and boiler drum level should be the same;

3, balance container connected to the boiler steam drum flange dimensions or welding interface specification should;

4, pay attention to: the balance container before installation must be conducted for boiler pipe blowing, prevent impurities from entering the balance container, and a serious accident.

5, will balance the container of soda interface respectively with outer drum isolation valve welding, ensure the vertical installation.Due to the double room balance container heavier, so need at the bottom of the channel steel support, and the bearing surface should be smooth.In order to prevent the equipment due to thermal expansion displacement and damage.

6, after the installation, the soda sampling sampling pipe, valve, pipe, cylinder should be tested for insulation treatment, cylinder at the top do not heat preservation.

Nine, when placing order, please provide the following parameters:

1, model specifications;ZW - FP;

2, the name of the measured medium, medium density: if you don't know the density, can tell us the name of the medium.

3, instrument measuring range: can also be referred to as the nominal length, namely the center distance of two flanges;

4, work stress: zui high pressure;

5, working temperature: high and low temperature measuring liquid;

6, material requirements: the liquid material.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.