Electric contact water level gauge

Products overview:

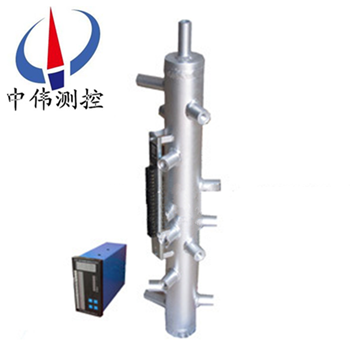

ZW - UDZ seriesElectric contact water level gaugeMainly used in boiler steam drum, high-low heater, deaerator, evaporator, dc starting separator, boiler water tank water level measurement, etc.This device is composed of measuring cylinder and secondary instrument, red, adopts digital display and steam aqua green double color led display level.Electrodes measuring cylinder in water of the impedance of the barrel is small, in the steam cylinder of impedance.As the change of water level, the number of electrodes in the water changes, into the change of the resistance value, transferred to the secondary instrument, so as to realize water level's display, alarm and interlock protection, etc.

Second, the working principle:

ZW - UDZ series electric contact water level gauge due to the conductivity of water and steam are very different.To measure the effect of drum water level is to change by the change of the electric contact resistance to obtain the signal.Electric contact insulator can make electric contact and the measuring cylinder shell insulation, when liquid, due to the low water resistance, the electric contact and the measuring cylinder shell through.When add a voltage between the electric contact, the flow of electric current is big, can make the secondary instrument in the integration of the op-amp, is on the front panel color light-emitting tube will show "green" color;On the other hand, not immersed in liquid surface of electric contact in the vapor state, because of the steam resistance value is bigger, can be relatively as open circuit, the flow of electric current is small, the secondary instrument of integrated op-amp not flip, on the front panel display "red" color luminous tube.Therefore, the water level of high and low depends on electric contact immersed in quantity, namely how much depends on the "green" color luminous tube.

Applications:

ZW - UDZ series electric contact water level gauge is mainly used in monitoring the boiler steam drum water level, the high pressure heater and low pressure heater and deaerator, evaporator, condenser, once-through boiler startup separator and the double water cooled generator within the tank water level measurement and other conductive liquid level measurement, but shall not apply to the flammable and explosive medium.

Four, the main features:

1, has the flash, voice alarm function.

2, 4-20 ma output signal, can connect DCS system, equipped with protection interlock function, of output.

3, have the function of the power supply, can continue to work when the power is 4 hours.

(4), instrument equipped with three buttons, a alarm sound attenuation, blowdown button b, c test button.

Five, the technical parameters:

1, the power supply voltage: 220 v + 10%, 50 hz;

2, working environment temperature: - 10-45 ℃.

3, work relative humidity: 85% or less;

4, liquid water resistance range: 0-500 k Ω;

5, relay contact output capacity: 220 v, 3 a,

6, water level display points: 5 to 19 points (up to 38 points, for example: 19 o 'clock 0, + 15, plus or minus 30, plus or minus 50, + 75, + 100, + 150, + 250, + 300;

7, appearance size: 800 mm * 160 mm * 300 mm;

8, installation size: 15 mm * 76 mm;

8, the engine power: 5 w or less.

Six, measuring cylinder and electrode:

1, measuring cylinder manufacturing standards according to the national machinery industry standard JB/T6691-93 boiler electricity contact liquidometer technology conditions for manufacturing, production, inspection.

2, electrode (electric contact) is made of super pure ceramic manufacturing.Structure is divided into two kinds: pressure into the type and screw type.

Seven, installation and use, and matters needing attention:

1, will be a meter (sampling tube) and the measured container with cut-off valve connected, and the sampling tube bottom valve and discharge pipes installation.

2, secondary instrument (display instrument) inspection and calibration

A, preparation: the input terminal of instrument adopt 36 core clamper, 35, 36 terminal to connect power.20 terminal resistance box at one end, a line resistance box at the other end.Resistance of the water quality of the measured medium large, usually like to measured medium in addition to salt water (such as the boiler steam drum water) can be selected 100 k, such as for tap water can be selected 10 k measured medium, such as no resistance box can be replaced with the corresponding resistance.

B, connected to power supply: LED light shows red, then put the other end resistance box pinout sub 1 ~ 19 terminals respectively, simulation of light green, as a condition of digital tube display the liquid level corresponding values, to show his instrument can work normally.

C, alarm location: open or short circuit set the alarm point respectively, measurement, observation stations is normal, if contact output action.

3, the primary instrument and secondary instrument wiring diagram.

4, alarm and protect contact output, the user can according to need to add the middle control device.

5, the sampling tube once that each class should be as follows:

A, "sewer" button;

B, first close the communicating pipe cut-off valve, then close connected on the cut-off valve, and then open the drain valve to drain;

C, close drain valve, open the communicating pipe cut-off valve to flush of electric contact, again under the closed pipe cut-off valve, open the sewage discharge valve;

D, close drain valve and open the first on the connecting pipe cut-off valve, and then open the communicating pipe cut-off valve, at this point the entire sewage work over.

E, click the "reset" button, the instrument into the normal operation.

6, instrument alarm sound, click on the "mute" button, the buzzer sound.

7, the electric contact on the sampling tube should be checked regularly, wipe the dirt from the insulators, lest cause false level;If any, should be replaced in a timely manner, to ensure the normal operation of the instrument.

8, built-in W1 potentiometers for water resistance to adjust potentiometer.Instrument adjusted when delivery from factory at about 150 k or less.

9, equipped with autonomous power supply will be short answer the machine, please.

10, should be added when using analog signal output signal isolator.

Eight,Selection of code:

model | generation | code | instructions | ||

ZW-UDZ- | - | -□ | -□ | -□ | |

Pressure of work | O1S | ≤4.41MPa | |||

Working temperature | 01S | 250 or less℃ | |||

Measuring points | 11 | 11point | |||

use | Q | bubble |

Nine, selection of details:

The product name | model | Rated conditions | According to pick up points | Transmitting range |

Boiler drum water level measuring cylinder | ZW-UDZ-02S-19Q | P=15.68Mpa | 19 | ±300mm |

ZW-UDZ-02S-17Q | 17 | ±250mm | ||

ZW-UDZ-01S-19Q | P=4.41Mpa | 19 | ±300mm | |

ZW-UDZ-01S-17Q | 17 | ±250mm | ||

ZW-UDZ-01S-15Q | 15 | ±200mm | ||

ZW-UDZ-01S-13Q | 13 | ±150mm | ||

ZW-UDZ-01S-11Q | 11 | ±100mm | ||

Measuring cylinder of high pressure heater | ZW-UDZ-02S-17G | P=15.68Mpa | 17 | 0~1000mm |

Deaerator measuring cylinder | ZW-UDZ-01S-17Y | P=4.41Mpa | 17 | 0~1700mm |

Ten order, design guidelines:

1, please users read the instructions before you order, or product introduction.

2, provide the measuring point distribution (table 2) that is outside the scope.

3, indicate the alarm, and protect the output position (set).

4, clear an instrument (sampling tube) working pressure, and communicating pipe size of center distance, which leads to the flange specifications.

5, this instrument can take 4 ~ 20 ma, 1 ~ 5 v, 0 ~ 10 ma dc signal output, the user need when ordering, please indicate.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.