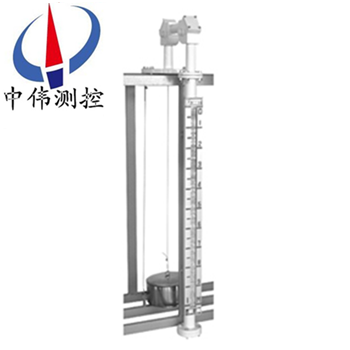

Float liquid level gauge

Products overview:

ZW - UFZ seriesFloat liquid level gaugeBased on buoyMeasuring element, through a set of pulley and steel wire will be measured medium level of exposure or low pressure container indirect indicator of a field measuring instrument, it is suitable for the corrosive medium trough of petrochemical storage tank system, tank, oil fields, oil and other industrial oil tank cover vault container flat cone and general enterprise, civil construction water tower (box) level measurement, and solved the tank level measurement and using artificial roof steel measurement difficult problems, such as, the product has beautiful shape structure, strong and direct reading, eye-catching, large measuring range, etc.In a wide range of highly corrosive, high viscosity and no precision measurement occasions, is particularly applicable.

Second, the working principle:

ZW - UFZ series float liquid level gauge is based on mechanical balance principle, design and production.When the liquid level in a highly buoy weight W, heavy hammer pointer (float) weight W1, buoy dipped in the liquid by the buoyancy of F, system friction to F.

Under the balance: W - F - W1 - F = 0

When liquid level rise, increase buoyancy F, W, W1, and F are the same, type balance, heavy hammer pointer (float).Until F force to reduce to its original value, a new equilibrium was established.Such as F force has been increased, the liquid level has been on the rise, pointer has been falling.On the other hand, the liquid level drops, the heavy hammer pointer to rise, to indicate the height of liquid level.

When the steel belt submerged floating in a certain position in the liquid static, float, wire rope (or strip), heavy hammer and pointer by gravity, liquid steel belt suffered buoyancy and system friction in balance.F will change when the liquid level changes, buoyancy, system balance disturbance will reach dynamic equilibrium.Lead the change of liquid level float position change, heavy hammer to drive a pointer moved up and down, on the scale can be clear and intuitive display container liquid level change.Gauge plate at the top of the zero mark the liquid surface, the bottom of the label on the surface of the liquid full scale.Pointer changes as the change of material level, and then continuously indicates the level of high and low.

Applications:

ZW - UFZ series float level gauge has many years of history, production technology mature.Has reasonable structure design, excellent performance, reliable operation, long service life, easy installation and maintenance, reasonable price, etc.Widely used in petroleum, chemical industry, fertilizer industry, rubber, pharmaceutical, Marine, military, electric power, food and other industries of all kinds of tajikistan, cans, and spherical pressure vessel and boiler equipment, such as medium level position indicator and automatic control.

Four, the structure of the instrument:

ZW - UFZ series float liquid level gauge is composed of buoy, connecting wire, guide pulley, heavy hammer pointer, a ruler and five parts.

1, buoys: stainless steel or carbon steel buoy system into a hollow circle, and welding have guide ring on both sides of buoy up the guiding role, the role of the buoy is the buoyancy of the liquid level changes directly to wire, make the wire weight pointer will change to liquid level, realize the liquid level change on site instructions.Saves (container with floating plate when the guide ring, can also save float ball, directly connect the wire and floating plate).

2, connecting wire, one end of the connection wire hanging buoy, the other end of the connection weight pointer, middle part closed within the steel pipe, steel pipe length is generally around 80-1000 - mm, according to the specific circumstances to determine.

3, guide pulley: it is according to the liquid level tank geometry and instrument installation requirements of design, and the connection wire guide pulley roller shell in two parts of check and ratify, main effect is to connect the wire guide and system of rotational resistance decreases.

: 4, heavy hammer pointer is made from alloy metal, middle made form of pointer, pointer refers to the corresponding scale numerical is the measurement of liquid level height, it is along with the change of buoy synchronous movement in accordance with the connection wire.

5, and display scale: it is made of sheet metal pressing, and engraved on the surface is good standard values, in cm, each section height of 1 meter.

Five, the main features:

1, in open hole on the side of the container is not appropriate, and the container around less space, can install in the container to the upper or lower this form liquid level meter;

2, can be used for a wide viscosity of liquid medium;

3, display the observation direction can be arbitrary change;

4, equipped with liquid level switch and control switches in the transmitter, can install at any time without stop;

5, if the power supply, the switch.Also is not affected, the accuracy is high;

6, every 10 minutes to add a different colored liquid, the liquid.

Six, the technical parameters:

1, the measuring range: 0-20 m in arbitrary choice;

2, index accuracy: plus or minus 20 mm;

3, working pressure: the atmospheric pressure or + 200 mmh20 (with v-shaped sealing tube);

4, medium density: acuity 0.6 g/cm3.

5, guide wire installed straight degree: + / - 5 or less;

6, material: according to the fluid part 1 cr18ni9ti;

7, indicator scale aluminum alloy.

Seven, installation and debugging:

1, according to the two guide roller spacing, hole above the container welding flange (in case and guide pulley flange connection);On the outside of the container welding rod bracket, height will be subject to keep the two guide pulley level.Container with floating plate, container hole at the top of the vertical line accordingly with floating plate intersect position should also open hole, for steel wire through.

2, instrument to zero

In instrumentation installation, tank should be haven't measured medium, buoy at the bottom of the tank, heavy hammer pointer part of the red point indicator should point at the top of the gauge measurement range of "zero" value, or to adjust the length of the wire.

3, instrument range adjustment

Instrument on the basis of the set zero, then pull the float to the top of the container or zui, large survey points on heavy hammer pointer part of the red point should be refers to the position in the bottom of the scale, which falls on scale zui point in a wide range.

Eight, installation, use and the matters needing attention:

1, under the guide wire support welding installation:

At the bottom of the container according to the requirement of level gauge buoy movement direction position, welding and riveting fixed bearing under the guide wire

2, guide the installation of the steel wire:

(1) make hard wire straightening, and fixed on a supporting, be careful not to make the wire has bends or knot phenomenon, so as not to affect the buoy moves up and down.

(2) the guide wire through the ear hook the buoy's guide, after wear into the hook screws, fixed the wire terminals with wire clamp clamping, and tighten the hook on the nut, the tension, spelled on the nut tight again, in case of loose, then cover block.

(3) the two vertical root guide wire to the ground, and parallel to each other, ensure the distance between the two is 300 mm

3, container with floating plate, with floating plate installed at the same time, eliminate the above steps 1 and 2.

4, scale installation:

The length of the scale is provided by the user in order, set the measurement range of the installation requirements:

(1) the connecting part of the scale should be flat, smooth, should not have bump phenomenon, so as not to affect the normal operation of the heavy hammer pointer, or cause measurement error.

(2) the rod should be vertical, with h inside the tank should be tilted phenomenon, scale installation of vertical degree is not greater than 5 °, lest cause heavy hammer pointer jammed, make measuring failure.

(3) when the welding rod horse, should try to do the installation surface on the same plane, mounting holes on the same straight line, namely, do ensure that the scale of the scale surface and heavy hammer pointer on both sides of the guide to flat as straight line, the flexible lifting heavy hammer pointer in the scale.

5, buoy connecting wire and the installation of heavy hammer Pointers:

Buoy and connect one end of the wire with the lead chuck fixed clamp, and then the other end of the wire will be connected into two guide pulley box installed in advance, and connected with a heavy hammer pointer, with wire clamp clamping, adjust the guide pulley bracket after zui, make the connection wire and horizontal vertical, making the buoy on the guide wire activity, there is light slippery feeling, no card dead, distortion, the phenomenon such as knot, curly or damage.

Nine, selection of code:

ZW-UFZFloat liquid level gauge (wei measurement and control) model | |||

1 Carbon steel ball | |||

2 Stainless steel ball float | |||

L Measuring range mm | |||

L1 Install the spacingmm | |||

ZW-UFZ | 2 | L=1000mm | L1=500mm p=0.8g/cm For example, |

Ten, design selection and ordering information:

1, indicate the specification of the liquid level meter, model;

2, measuring range L;

3, and measured medium medium humidity, temperature;

4, the size of the installation distance L1.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.