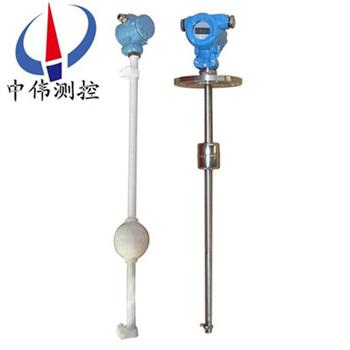

Ball float liquid level gauge

Products overview:

ZW - UQZ seriesBall float liquid level gaugeMainly by the maglev ball, sensor and transmitter of three parts.Adopts 304 stainless steel, PVC, PTFE and other materials for protecting tube and installation fixed parts;For strong corrosive medium, adopt ptfe sintering in contact medium metal protection tube, the surface of the floating ball, to ensure that the liquid level meter is not corrode.According to user requirements the preset magnetic sensor, float with the liquid surface movement change the default state of magnetic sensor signal on-off, realize the monitoring of the liquid surface.

Second, the working principle:

ZW series - UQZ float liquid level gauge is when the maglev ball change with the liquid surface, floating up and down along the tube, floating ball in the magnetic steel and sensors in the corresponding position of dry reed pipe sensor is a change in the total resistance by the transmitter will change again after the resistance of the signal is converted into 4-20 ma electrical signal output, and through the digital display control instrument or column display device to remote measurement of liquid level, and on the display set upper and lower limit alarm, realize remote digital control of liquid level.Can also be composed of other regulator level constant value control computer control system, realize the PID for remote control of the liquid level.

Applications:

ZW series - UQZ float liquid level gauge is suitable for the oil refining industry, chemical industry, paper making, food and pharmaceutical industries, and applicable sewage and all kinds of exposure or pressure containers within the medium level measurement, for underground storage tanks and high-level water tank level measurement is the ideal instrument.Liquid level meter made of stainless steel or anti-corrosion materials, and has a flame-proof protective performance.

Three, the main features:

1, the SMD technology, improve equipment reliability.

2, automatic power adjustment and gain control, temperature compensation.

3, advanced testing technology, rich software function to adapt to all kinds of complicated environment.

4, with new waveform computing technology, improve the measurement precision of the instrument.

5, with functions of clutter echo of dampening guarantee real measurement data.

6, 16 bits D/A conversion, improve the accuracy and resolution of output current.

7 tetrafluoroethylene materials, sensors, can be used for various corrosion occasion.

8, multiple output format: programmable relay output, high precision 4-20 ma current output.

Four, the technical parameters:

1, the transducer length: 6000 mm or less (optional);

Measuring range: L 5500 mm or less;

Installation height: H 5700 mm or less;H - L 200 mm or less;

2, plus or minus 1.5% accuracy in the transmitter (measuring height H > 1000 mm), plus or minus 1.5% (measuring height 500 mm H 1000 mm or less) or less.

3, the output signal: 4 ~ 20 ma two wire system;

4, output load: 90 ~ 1 k Ω, 0 ~ 500 Ω;

5, junction box shell protection: I P65;

6, measuring medium temperature: - 20 ~ 130 ℃;

7, measuring medium pressure: 0.6 Mpa or less;

8, measuring medium conditions: 0.07 or less viscosity PaS.Acuity 0.8 g/cm3 density;

9, floating ball, standard delivery ¢150 (guide for 25 ¢);

Special supply ¢56 (guide for ¢12);¢29 (guide rod is ¢7.5).

Five, the installation instructions:

1, UQZ ZW - type instrument.

2, should not be measured medium containing ferromagnetic impurities.

3, in order to prevent the transport float in a sealed tube on the slide or collision, cause measuring tape out, the meter before they go out, use clamp to fix floating ball in the seal at the bottom of the tube, magnet steel on the top of the sealing tube.Users should be down clamp before install and use, will float up to sealing pipe top, then gently to float down, should make the corresponding rotational beard needle.

4, the face of the instrument instructions for pointer, full instructions digital measurement for gel injection direction is arranged, when an empty measure indicator for inverse direction when the needle.

5, instrument factory with flange installation, the user should match pipe flange.

6, instrument installation position generally choose the half range.

Six, divided into the following four kind of installation method:

A: B: overhead installation side side mounted C: side bottom mounted D: support installation

(when placing order, please indicate the type of installation and long length L value.)For exposure or non-metallic containers, can be used in a scaffold installations.For exposure or non-metallic containers, can be used in a scaffold installations.

Seven, install and use need to notice:

1, level gauge putting-in-service proactively after a period of time, present float to float and float move not sensitive situation.This is fundamentally due to the magnetic float was matted with iron filings or other contaminants.Can be emptying medium first, and then remove the float, eliminate some iron filings on magnetic float or other contaminants.

2, occasionally found in field calibration float up and down move not sensitive enough.This is mostly due to improper level meter device made up of, at this time to pay more attention to the center of the upper and lower flange can be in a line, with the degree of surface vertically.Common, and the degree of surface Angle of not less than 87 degrees, if deviation is bigger, may impact the float move smoothly.

3, when choosing the Ann type liquid level meter, especially to pay more attention to the level and peace can grid impedance matching.

4, level gauge calibration is normal, after putting-in-service proactively find float in a position to present "absorb" phenomenon in a period of time.This device is mainly the level through the steel platform, and the steel plate spacing too close.Therefore, through the steel platform device needs special attention to the level of pipe wall and platform cutting line spacing.

5, liquid level meter used in the process, if the output signal frequency pulse disturbance or interference, check signal cable shielding layer can be reliable grounding, work is meet the request of the resistance.

6, level gauge field putting-in-service proactively, to pay special attention to should be opened the upper gate, opened lower after the gate.This is due to the level of at the bottom of the pipe is equipped with maintenance float the thrust of spring, otherwise, the role of big differential pressure level meter can crack-up float incurred cannot use.

7, if due to transport or other reasons cause the instructions with airtight glass tube rupture, usable domestic glass tube to change.But can vacuum.Also, be aware of glass tube can be vertical, lest affect indicator's instructions.

8, level gauge particularly want to pay attention to when using, don't use strong magnet pull float up and down outside the pipe stop check, or you will incur magnetization of the magnetic float and polarity changes, so that can make the magnetic float, which is difficult to work properly.

Instructions:

1, key operation:

Adjusting the zero key [Z], [S], function keys [M] | ||

Operating content | Operation method | note |

Button to open the | At the same time press the [Z] and [S] key more than 5 seconds, you can OPEN the (LCD screen display: OPEN). | |

PV value zero (The zero adjustment) | Will float on the zero directly, on the keys, and at the same time press the [Z], [S] key more than 2 seconds, can the current PV value is set to 0, (the LCD screen display: PV = 0) | If the current PV value with zero value deviation exceeds 50% FS, PV value zero is invalid, (LCD screen display: PVER) |

Four ma active migration | Button to zero: put float at zero, press the [Z] button 2 seconds, transmitter output 4 ma current, complete zero operation.(LCD screen display: LSET) | |

20 ma active migration | Key tone: full will float in a full, press the [S] button 2 seconds, the transmitter output 20 ma current, complete the full operation.(LCD screen display: HSET) | |

The transmitter data recovery | Press [Z] key, and then put through power supply, continue to hold the [Z] more than 5 seconds, if the LCD screen display OK, then have the transmitter data back to the factory state, can loosen the buttons, if the LCD display FAIL, says express not transmitter for data backup, data recovery cannot be transmitter to the factory state. | |

if2Within minutes without any button press, transmitter keys locked automatically, if you want to operate, need to open again.The above operation, the use of the zero key 【Z", the full key"S】 can be realized, and the two key transmitter board the above instructions.Without a header display external current meter can also achieve adjustment.

2, measuring parameter Settings:

Measuring parameter Settings, continuous press the function key"M】 will be displayed in turnZERO、SPRN、DPMP、DISP、FIX C According to the function keys after zui confirm and exit sets back show status.

According to the content | Set the content | Operation method | |

0.888 ZEPO CM | Set up the4mAPoint range | According to the[Z]Key revision number or a decimal point | According to the[S]Key numerical or decimal point position adjustment |

100.00 SPRN CM | Set up the20mAPoint range | Same as above | Same as above |

2.000 DPMP S | Sets the damping time | Same as above | Same as above |

12.008 DISP mA | Set the display mode | According to the[S]Choose the display mode button(According to liquid level, current, percentage) | |

3.6 FIX C CM | Fixed output current | Output screen display the current value(3.6、4、8、12、16、20、22.8mA) | |

Explanation: the parameter is set, if2Minutes no button pressed, the direct return to measuring mode (not save Settings data).

Nine, selection of code:

type No. | generation code | said Ming | |||||

ZW-UQZ | -□ | -□ | -□ | - | - | - | The ball float liquid level gauge (wei measurement and control) |

Range (mm) | range500mm<H<5500mm | ||||||

Medium density | kg/m3 | Density >0.7 | |||||

installation | 0 | Bracket installation | |||||

- 1 | DN80 PN0.6 | ||||||

2 - | DN100 PN0.6 | ||||||

-T | Special instructions | ||||||

Answer the liquid material | 1 | 304 | |||||

2 | 316 | ||||||

3 | PP(Atmospheric pressure) | ||||||

4 | Special instructions | ||||||

The output signal | 1 | current4~20mAThe output24VDCThe power supply | |||||

T | Special requirements | ||||||

Display mode | N | Don't take the display function | |||||

LED | With the function of live shows | ||||||

Ten, design selection and ordering information:

1, when you order it to indicate the type, medium density, temperature, pressure, insert depth (L) (L), measuring range, the flange standard, specification, quantity,

2, if you have special request, please specify when ordering.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.