Radio frequency admittance continuous level meter

Products overview:

ZW - L2000D seriesThe rf admittance level meter in a rowDue to the "radio frequency detection technology" and the modern microcomputer processing technology, has solved the traditional material level meter large temperature drift, calibration, afraid of the problem of adhesion, widely used in various industries liquid, particle and block bin continuous measurement of material level.This product USES the special impact resistant, wear resistance, sheath maerial sheath materials for domestic initiative, especially suitable for high temperature, high pressure, strong corrosion, strong adhesion, strong wear and dust under the environment of the measurement, there are other types of material level meter unmatched by comparison.

Second, the working principle:

ZW - L2000D series continuous material level meter is a kind of radio frequency admittance from the capacitive level measurement technology, prevent hanging, more reliable, more accurate, applicability broader level control technology, the meaning of the admittance of radio frequency admittance for electrical impedance in the bottom, it is composed of resistive composition, composition of capacitive and inductive components integrated.And rf namely launch high frequency radio waves, so the rf admittance level control technology is by using high frequency radio waves admittance measured medium to realize the material level measurement.

For continuous measurement, the difference between the rf admittance technology and traditional capacitor technology in addition to the above mentioned, also added two very important circuit, which is based on conductive hanging the discovery of a very important in practice to improve.The above techniques when also can solve the problem of connecting cable, also solve the problem of the vertical installation of sensors roots hanging.Lock the two circuits are oscillator buffer to increase and communication transform chopper drive.

Applications:

ZW - L2000D series rf admittance continuous material level meter unique mechanical probe design, match with high performance transducer, high cost performance, in metallurgy, petrochemical, chemical, grain and oil, food, cement, rubber, beer, beverage and other industries have widely used in all kinds of material level.

1, conductive, insulation liquid, chemical industry, oil field, water and wastewater treatment;

2, conductive, insulation liquid, paper making, pharmacy, water and wastewater treatment;

3, powder, powder, power plants, metallurgy, cement, ash and;

4, grain, coal, grain, power plants, metallurgy, food;

5, interface: two kinds of different liquid, oil field, chemical industry.

Four, the main features:

1, in the design: two wire system safety design, unit and probe are intrinsically safe;

2, avoid d n: no moving parts, will not result in a worn or damaged, not regular cleaning, do not need to repeat debugging;

3, hanging: electrical design allows it to ignore the influence of the hanging wall hanging or sensing element;

4, chemical compatibility: multiple probe design, meet the requirements of all kinds of medium;

5, wide application: process temperature from 183 ℃ to + 815 ℃, pressure from vacuum to 100 bar;

6, no drift move: not because of medium temperature or density change of drift;

7, reliable life: unique technology ensures the service life of the instrument over 15 years;

8, safety protection: built-in sensor input protection, protection ability, less susceptible to static, impact and electrochemical phenomena or damage;

9, installation is simple: the instrument can be installed by mouth thread or the flange on the tank, can choose whole or fission installation, simple and convenient, easy to debug, and fast.

Five, the technical parameters:

1, power supply: 18 v - 30 VDC;

2, output: 4-20 ma (two wire system);

3, the output mode: level way or distance way;

4, accuracy: + / - 1%;

5, environmental temperature: - 40 ℃ ~ 70 ℃;

6, medium temperature: - 100 ℃ ~ 260 ℃;

7, zui big load: 350 Ω 24 VDC;

8, load effect: 0.2% (0 - zui large load).

9, response time: 0.5 ~ 0.5 s (standard) 30 s (adjustable);

10, the scene show that can be displayed with the function (optional);

11, amount of cheng: z 15000 pf, z big distance of 100 m (z) in a wide range from different sensors;

12, spark protection (of sensor) : built-in spark protection circuit;

13, electrical interface: M20 * 1.5;

14, the electric cable: split type electronic unit dedicated connections between the sensor and cable standard 5 m, zui 50 m long;

15, process connection: the NPT thread installation (standard);

16, flange installation (optional);

17, shell protection: IP66;

18, explosion-proof: Exidllct4.

Six, installation requirements:

1, designed for field installation type, but it remains to be installed as far as possible away from corrosive air and vibration can cause mechanical damage.To facilitate debugging, the instrument shall be installed where have operation platform, or similar platform.Environmental temperature should be - 40 ~ 75 ℃ (140 ~ 75 ℉).Ray device, instrument installation area wall in case of a lightning strike.

2, instrument installation, must guarantee that the center of the sensor sheath maerial and shielding layer and vessel wall (or installation) each other contact, good insulation, install screw connected to the container is firm, good electrical contact, and the sensor's side will enter inside the container.For large range or places that have requirements of mixing, sensor need support or anchor is fixed, but fixed end insulation and sensors.

3, according to the requirements of explosion-proof instrument installation, wiring of each connected with explosion-proof enclosure must be equipped with have certification of seal stuffing box or explosion-proof steel tube seal joint.According to the requirements of the installation of the instrument, each time a road must be equipped with a security gate has been certified.Certification of seal stuffing box or explosion-proof pipe seal joint and safety barrier products please consult the company or agent of the company.

4, 24 VDC power supply ripple shall not be greater than 200 mv.Power supply ground to pick up in the standard or standard instrument, can't connect the power on the ground.The power cable shielded cable, is recommended for the long distance without shielding and parallel ac power cable.Cable through region requires wall thunder device, in case of a lightning strike.

5, according to the requirements of explosion-proof instrument installation, open the instrument at the scene of the explosion explosion proof shell, before must be convinced that the instrument has been without electricity for power and has more than 10 minutes.

Seven, note:

1, the radio frequency admittance installation location not being too close to the mouth, otherwise, rf admittance level meter when the material is easy to receive fake echo.

2, rf admittance for the original coal cylindrical, VEGA should be installed in the cylinder radius in half, the sensor should be aimed at discharging port.

3, rf admittance model is needed for the different voltage grade are not identical, to ensure the personal safety and equipment in good condition, should be in the case of power wiring.

4, connection mode can be divided into two wire system, rf admittance level meter acquisition is 4-20 ma current signal, to prevent electromagnetic interference on site, ensure the accuracy of signal, should use shielded cable, shielding grounding cable end.

Eight, installation method.

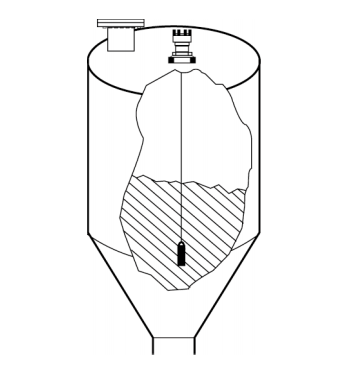

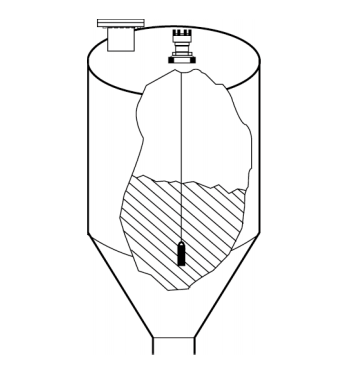

1, with rod or cable out bucket tank liquid level measuring pole:

Note: sheath maerial or cable should avoid, into the mouth, and sheath maerial or ground line parallel to the silo wall.Distance between the warehouse wall thrown and 200 mm.

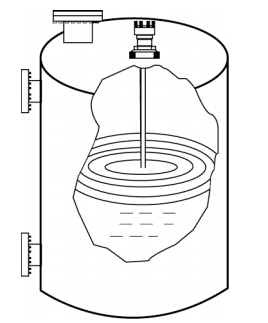

2, horizontal tank is measured with a coaxial agent very level:

Note: the bucket pot and non-metallic silo wall can use coaxial agent is measured.

3, with unicom measuring spherical tank liquid level:

Note: spherical tank and other irregular shape tanks are the unicom apparatus can be used for measurement.

4, with heavy cable-type agent powder or fine grain bin level:

Note: the agent should avoid inlet, when the silo wall is concrete sensor shell earthing terminal shall be reliable and concrete reinforced with wire connection.

Nine, selection of code:

ZW-L2000D | Rf admittance level meter (wei in the measurement and control), hanging heavy resistance, with the switch status indication, independent junction box | ||||||||

2 | 24VDC | The power supply mode | |||||||

3 | 220VAC | ||||||||

0 | Standard acuity | Unit circuit sensitivity | |||||||

2 | High sensitivity | ||||||||

0 | No time delay (standard circuit units) | The time delay | |||||||

1 | With time delay adjustable (0 ~ 60 seconds) (optional) | ||||||||

2 | With time delay adjustable (0 ~ 90 seconds) (optional) | ||||||||

- | 9 | one-piece | The instrument type | ||||||

0 | Split type | ||||||||

02 | Standard temperature (< 121 ℃) | The electrode type | |||||||

07 | High temperature (temperature < 232 ℃) | ||||||||

20 | flat | ||||||||

22 | Heavy hanging standard | ||||||||

30 | Flexible probe | ||||||||

55 | The corrosion type | ||||||||

- - - | Range range (mm) | ||||||||

ZW-L2000D | 2 | 2 | 1 | - | 9 | 02 | Rf admittance level meter | ||

Ten, electrode selection:

Electrode number | Electrode form and typical applications | Working temperature and working pressure | The length of the | The electrode diameter And the material | Install the connection In the form of |

02 | Standard: used for liquid, light slurry, granule (density 240 kg/m or higher3) | 121℃/1.38MPa | 457mm(18") | 9.5 mm / 316 ss and PTFE | 3/4"NPT |

07 | High temperature type: used for liquid, slurry, granule (density 240 kg/m or higher3) | 232℃/1.38MPa | 457mm(18") | 9.5 mm / 316 ss and T1 | 3/4"NPT |

22 | Light weight hanging standard: for mixing liquid, slurry, granule (density 240 kg/m or higher3) | 149℃/3.45MPa 232℃/1.38MPa | 457mm(18")/ 914mm(36") | 12.7 mm / 316 ss and TFE | 1"NPT |

55 | Light corrosion type: used for liquid, slurry, granule (density 240 kg/m or higher3) | 232℃/1.38MPa | 457mm(18")/ 914mm(36") | 9.5 mm / 316 ss and T1 | 3/4"NPT |

20 | For flat probe: chute, hopper jam detection, low material level | 149℃/0.007MP | 304.8 mm (12 * 12 ") / 304 ss and polyurethane | built-in | |

30 | Flexible probe Used for high/low level insert > length of 15 m | 82 ℃ atmospheric | 15m | 4.7 mm / 304 ss and rubber | 1"NPT |

Note:1、PTFEFor ptfe;2, more than for the standard length, can according to user requirements production level gauge length.

Eleven, design selection and ordering information:

1, liquid level control device specifications;

2, measurement range;

3, working pressure, and temperature;

4, control device for material;

5, special requirements;

6, whether level device matching supply vessel flange, bolts, nuts, valves and fittings such as sealing washer, so that the correct selection.

After-sales service commitment:

1, my company the liquid level switch series of products are sold within 12 months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.