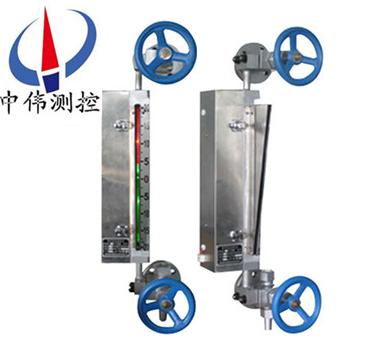

Long window type two-color water level gauge

Products overview:

ZW - B69X seriesLong window double color water level gaugeAdopting the new pressure on the structure, make the Windows wider, use cold light source through the red, green, transparent glass, refraction, make the observation effect is more ideal, at the same time, on the basis of the original water level gauge has been a major reform of the sealing technology, and adopt the new sealing material, change the previous table body easy to leak faults, prolong the service life and maintenance cost greatly reduced.Designed for large thermal power unit boiler steam drum water level monitoring and the design and manufacture of in situ instrument, can also be used to other industries of water level monitoring.

Second, the working principle:

ZW series - B69X long window double-color gauge through steam, water valves and steam drum side and water side connected to form the tower, the use of the principle of communicating vessels so that water level gauge water level consistent with steam drum water level.Is, of course, after the normal operation of boiler, because inside the boiler steam drum and field of temperature in the water level gauge is different, can cause the proportion of interior and exterior saturated steam boiler steam drum water is different, so the water level gauge shows that steam drum water level with the actual boiler water level there is a certain difference.

Applications:

ZW series - B69X long window double-color water level gauge is mainly used for power plant high temperature and high pressure steam boiler water level gauge observation hole, transparent, wave, high temperature resistance, corrosion resistance, scouring resistance, insulation, smooth and clear, high frequency low dielectric loss properties.Can be used in high frequency medium, high temperature vacuum and high temperature and high pressure, strong acid, strong alkali, working environment, under the rapid changes in temperature and pressure also does not affect its chemical properties and optical transparency, and therefore is a coal-fired power plant, oil refineries, chemical plants, etc. High pressure steam boiler water level gauge of ideal material for protecting lining.

Four, the main features:

1, table body bolt hole, the water level gauge slitting line, table body plane and plate surface using fine grinding, don't let it out.

2, table body by two rows of compensation type window, dislocation type window, eliminated the original mica double-color gauge shortcomings of blind area;Bolt and rotary table body, prevent the bite silk, silk, change the deficiency of the past.

3, the two rows of Windows on the table, through optics refraction principle, right in front of gauge can observe the arrival time when you watch the water level up your bag and the water level value accurately.

4, light meat change, red, green, clear, clear boundaries.

5, water level gauge adopts long window structure, wide observation inspection, high transparency.

On 6, table body has three waterproof lines, and USES the special sealing material, not leak, prolong the service life of the product, reduce working intensity of maintenance personnel, reduce the maintenance cost.

7, cold light source adopts the new light source, long service life.

8, when the water level TV monitoring system is used, the drum water level and water level monitor synchronization, the picture is clear.

Five, the technical parameters:

1, nominal pressure: 16 mp, 25 mp, 32 mp;

2, the interface form: welding, flange connection;

3, temperature, saturated;

4, center distance: 535 mm - 1270 mm;

5, visual length: 380 mm - 800 mm;

6, light source: led, halogen tungsten lamp, flat tubes;

7, power transformer: 40 v input 35 v, 220 v output, 45 v power 600 w, 1200 w.

Six, product specifications:

1, no blind area (compensation) : five, five paragraphs long, 7, 9, 11;

2, no blind area (dislocation) : two, four, six paragraphs, eight, ten;

3, have blind area: three or four paragraphs;

Part 4, light source: led, halogen tungsten lamp, flat light could be selected according to user requirements.

Seven, mica components technical requirements:

1, the thickness of mica components with 16 mpa pressure is greater than 1.5 mm, with 2 mm thickness pressure is greater than 25 mpa, match 32 mpa pressure is greater than 2.5 mm thickness, formulate specific thickness according to user requirements and component plant size and pressure to determine the mechanical and electrical group.

2, water level gauge with mica sheet length error must not exceed 0.5 mm, the width of the error must not exceed 0.3 mm, bull 's-eye type circular gauge mica sheet error must not exceed 0.2 mm, the thickness of the single chip requirements within 0.1 0.25 mm.

3, mica sheet of high quality, transparent, smooth and clarity is good, the surface must not have impurities, scratches, spots, sand holes, layering and corrugated exist.

4, double-color water level gauge glass mica components with high temperature and high pressure aluminum silicon glass, glass size appropriate, no crack, scratch, good transparency.

5, other graphite gaskets, monel alloy cushion, cushion gasket, protection zones are also pressing, the thickness of the standard, smooth, no cracks.

* our factory equipped with various types of water level gauge mica spot sealing components, after receiving the order, with the express mail delivery immediately, users receive product just 3 days, ensure the quality of products in the premise, each group of water level gauge mica component price is 10% lower than the other manufacturers - 20%.Reliable quality, reasonable price, timely delivery.

Eight, maintenance and matters needing attention:

1, the water level gauge of components by artificial mica sheet, natural mica sheet and the graphite pad.

2, synthetic mica sheet contact medium, graphite pad when installation, must according to the size of the surface installation.

3, red and green glass in the same bracket, green glass on the right side of the table body, such as steam upside will be green and pink, the water level of misleading.

4, install the mica sheet correctly placed, the screw fastening clamp again, then diagonally fastening, strength gradually to 90 n. m, 120 n. m, n. 150 m and 180 n. m four times and tighten closely, ensure the smooth.

5, water level gauge for a long time to run the mica sheet may also scaling, at this time must be to wash.Washing method: close the valve, open the water valve, make the table body internal water rose to the top, 4-5 times, open the drain valve rinsed repeatedly.Mica components such as flushing impurities should be replaced.

Nine, selection of code:

ZW-B69X | Mica two-color level meter (wei measurement and control) | ||||||

code | The product type | Spec code | |||||

2 | The second section shows No blind area (dislocation) | ||||||

3 | Three sections of display (A blind area) | ||||||

4 | Four shows (A blind area) | ||||||

4-2 | Four shows No blind area (dislocation) | ||||||

5 | Five sections show No blind area (compensation) | ||||||

5-2 | Five period lengthen No blind area (compensation) | ||||||

6 | Six shows No blind area (dislocation) | ||||||

7 | Seven segment display No blind area (compensation) | ||||||

8 | Eight shows No blind area (dislocation) | ||||||

9 | Nine shows No blind area (compensation) | ||||||

10 | Ten video display No blind area (dislocation) | ||||||

11 | 11 shows No blind area (compensation) | ||||||

code | Stress levels | ||||||

1 | Pressure or less2.5MPa, the saturated steam temperature | ||||||

2 | Pressure or less4.0MPa, the saturated steam temperature | ||||||

3 | Pressure or less6.4MPa, the saturated steam temperature | ||||||

4 | Pressure or less10.0MPa, the saturated steam temperature | ||||||

5 | Pressure or greater10MPa, please note | ||||||

code | Measuring range | ||||||

L1 | 350mm | ||||||

L2 | 400mm | ||||||

L3 | 440mm | ||||||

L4 | 600mm | ||||||

L5 | 1000mm | ||||||

L() | Special specifications in brackets to fill in, please | ||||||

code | Answer the liquid material | ||||||

D | When ordering, please note | ||||||

code | The connection method | ||||||

F | Flange installation(Nominal diameter) is required to provide | ||||||

M | Butt welding (must provide connecting pipe outside diameter size) | ||||||

Special request, please note | |||||||

Ten, when placing order, please provide the following data:

1, model specifications: mica two-color level meter: ZW - B69X series;

2, the name of the measured medium, medium density: if you don't know the density, can tell us the name of the medium.

3, instrument measuring range: can also be referred to as the nominal length, namely the center distance of two flanges;

4, work pressure, work under pressure;

5, working temperature: the temperature of the liquid measuring;

6, material requirements: liquid material, such as don't know which one to use material;

7, whether matching supply flange, bolts, nuts, valves, fittings, such as sealing washer;

8, flange standard: nominal size of the flange, use flange is 3/4 "or DN25;

9, special requirements: before ordering, please indicate in detail.

After-sales service commitment:

1, my company product the level gauge series products are sold within 12 months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.