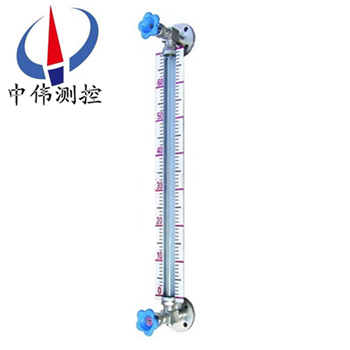

Monochrome glass tube liquid level meter

Products overview:

ZW - UGB seriesMonochrome glass tube liquid level meterIs a kind of direct reading type liquid level measuring instrument, suitable for industrial production process of general liquid liquid location of the site test of equipment, its structure is simple, measurement accuracy, is a traditional field level measurement tools.The level gauge at each end with a needle valve, when there was an accident and broken tube, needle valve automatically shut down under the pressure container, in case of containers within the medium to drain.

Second, the working principle:

ZW series of UGB monochromatic glass tube liquid level meter M27 x 1.5 are fitted on the top and bottom valve or ZG3/4 "nipple, through flange connected to the container constitute connectors, through the glass plate can be directly read container liquid level height.

Instrument in fluctuation in all equipped with ball valve, when the glass tube is destroyed because of an accident, steel ball within the container pressure blocking channels, so the container automatically seal, container can prevent the liquid to drain.

Applications:

ZW series of UGB monochromatic glass tube liquid level meter can be used with other digital display instrument supporting, avenue, a variety of control purposes.As a result, its wide range of use and electric power, petroleum, chemical industry, environmental protection, shipbuilding, construction, food and other industries the level measurement and control in the process of production.

Four, the main features:

1, suitable for container medium level of the liquid level, the position of the measurement.In addition to the instructions given also can match position transmitter, alarm, switch to far.

2, distance signal transmission.

3, indicating novel, intuitive reading and observation direction of indicator according to user needs to change position.

4, indicating device, and is completely isolated measured medium, good sealing, high reliability, the use of safe.

5, simple structure, convenient installation, low maintenance cost.

6, corrosion, explosion-proof, no power supply.

Five, the technical parameters:

1, the measuring range (installation center distance) : 350, 440, 500, 600, 800, 1000, 1200, 1400, 1700, 2000 mm;

2, work pressure measured medium: 1.0 (R - PP), 1.6 (glass), 2.5, 4.0, 6.4 MPa (quartz tube);

3, working temperature measured medium: - 10 ℃ ~ + 450 ℃;

4, steel ball automatic closed pressure: greater than 0.2 MPa weight: 15 ~ 30 kg;

5, heating steam pressure: 0.6 MPa or less;

6, steam jacketed joint: G1/2 "male;

7, interface flange: using chemical new HG20592 1997 ~ 20635-97 standard flange.

Six, installation, use and maintenance:

1, installation: glass tube liquid level meter is a precision instrument, the transportation, handling, must handle with care when unpacking and installation, must not impact, knock, prevent the glass broken, factory according to 1.5 times the PN pressure testing, users shall not remove the glass tube;

2, use: level gauge on the fluctuation of the valve flange to the container, the out pipe flange installation connection, first slowly open the valve, make the liquid scour the lining, such as the display is not clear phenomenon, after waiting for pressure stable which can clear, such as high temperature for liquid in the container, prior to the glass tube for preheating can be put into operation only half an hour, and in order to avoid sudden burst; by high temperature glass tube

3, maintenance: after long-term use, irrigation drainage, should be carried out on a regular basis can be shut off valves up and down, and then open the drain valve will be closed after liquid emptying, micro again open the valve for liquid filling the table after closing, zui, valve slightly open, open the drain valve, repeated rinse;If choose type needle valve during normal operation, the valve stem exit the turn number shall not be less than 4 turn, when the glass tube damage, guarantee the steel ball can automatically seal.

Seven, note:

1, the glass tube liquid level meter in the transportation, handling and installation, are not allowed to hit or knock, in case of broken glass tube and glass plate.

2, level gauge is installed, when the medium temperature is very high, do not immediately open valve, should be preheated 20-30 minutes, after waiting for glass tube has a certain temperature, then slowly open valve.

Open valve program: first, slowly open the valve, then slowly open the valve, the measured medium slowly into the glass tube.

3, liquid level meter in use, should be regular cleaning glass tube inside and outside wall of dirt, in order to keep the liquid level show clear.Cleaning procedures: first, close connection of the upper and lower valve, open the drain valve, put the net residual liquid inside the glass tube, using the appropriate cleaning agent or use the long pole ShuaLa MAO wipe method, clean up dirt tube wall.

4, hang dirty if the quartz tube rupture or serious need to change, the specific steps are as follows:

Remove the table body, unscrew nuts and nut on both ends, with a wooden stick to knock, quartz glass tube from one end to the other end out graphite ring, the new quartz tube into,

Then graphite ring set on the quartz tube, isometric embedding table body, tighten the nut and nut on both ends, after confirm no leakage, can be put into operation.

Applicable to alkaline acid environment.Alkali glass tube liquid level meter, acidic glass tube liquid level meter.

Eight, cleaning maintenance:

1, the use of liquid level meter check regularly.Clean dirt inside and outside wall glass, which liquid showed clearly.

2, in order to guarantee slip more than plan, containers within the medium pressure should be greater than 0.2 MPa, when open the upper and lower valve, the valve stem to exit the turn number not less than 4 turn (make steel ball FengMen, don't run into the top of the stem.)

3, containers and two flange end face of the glass tube connection shall be guaranteed in the same vertical plane, otherwise the valve in the liquid level gauge is installed deflection, so that the glass broken.

Nine, specification and basic parameters:

Nominal length L (mm) | Pervious to light length L (mm) | other | ||

A | B | R | ||

500 | 350 | 90 | 22 | 20 |

600 | 450 | |||

700 | 550 | |||

800 | 650 | |||

900 | 750 | |||

1000 | 850 | |||

1100 | 950 | |||

1200 | 1050 | |||

1300 | 1150 | |||

1400 | ||||

Ten, the classification of the material:

The serial number | The name of the | material | ||

I | II | III | ||

1 | Glass tube | BSi | BSi | BSi |

2 | scale | LF21 | LF21 | PP |

3 | Needle valve type | 20 | 1Cr18Ni9Ti | PP |

4 | Protective sleeve | A3 | 1Cr18Ni9Ti | PP |

Eleven, selection of coding:

ZW-UGB/F | In the glass tube liquid level meter (wei measurement and control) | ||||

Work pressure (Mpa) | |||||

- 01 | < 1.6 is suitable for the glass tube | ||||

. | 2.5 suitable for quartz tube | ||||

- 03 | 4.0 suitable for quartz tube | ||||

- 04 | 6.3 suitable for quartz tube | ||||

Material is qualitative | |||||

- 01 | 304 | ||||

. | 316 | ||||

- 03 | 304+F4 | ||||

The center distance L | |||||

Twelve, design selection order information:

1, model specifications;ZW series of UGB glass tube liquid level meter;

2, the name of the measured medium, medium density: if you don't know the density, can tell us the name of the medium, the mixed liquid to know by what kind of composition;

3, instrument measuring range: can also be referred to as the nominal length, which is the center distance of two flanges, or have a look at using scale label of products;

4, work pressure, work under pressure;

5, working temperature: measuring the temperature of the liquid;

6, material requirements: liquid material, such as don't know which one to use material, can consult us (usually with liquid is what material we can use what material);

7, whether matching supply flange, bolts, nuts, valves, fittings, such as sealing washer;

8, flange standard: nominal size of the flange, use flange is 3/4 "or DN25;

9, special requirements: before ordering, please indicate in detail.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.