Guided wave radar level gauge

Products overview:

ZWRD700 seriesGuided wave radar level gaugeThe high frequency microwave pulse along the detection components (wire or steel bar), measured medium, due to the dielectric constant mutation, cause reflection, part of the pulse energy is reflected back.Launch pulse interval and pulse and reflection is proportional to the distance of the measured medium.

Container in two different media, when a layer above medium dielectric constant is small, and medium dielectric constant of the larger, high frequency microwave pulse propagation along the detection components meet the upper medium, because of its dielectric constant is small, so there is little energy by this layer interface reflection, and most of the energy through the upper medium continue downward, meet two layer interface, due to the lower dielectric permittivity is bigger, so there will be a larger energy is reflected back.Thus guided wave radar is to measure the interface of two different medium, its measuring conditions are the upper medium non-conductive or its dielectric constant is smaller than the lower dielectric permittivity of 10 or more.

Second, the working principle:

ZWRD700 series of guided wave radar level meter is the measuring instrument based on the principle of time travel, very low energy is emitted by a very short microwave pulse by transmitting and receiving antenna system.Radar wave are running at the speed of light.Running time can be transformed into material level signal by electronic parts.Probe a high-frequency pulse and probe the conduction along the cable type or rod type, when the pulse in the material surface reflected by the receiver inside the instrument, and the distance signal is transformed into material level signal.A special type of time extension method can guarantee the stability of a very short period of time and accurate measurement.Even if the condition is relatively complex, false echo, with a new micro processing technology and debug software can accurately analyze the level of the echo.

1, the input:

Reflection of the pulse signal along the cable type or bar type probe to the instrument electronic circuit part, microprocessor to signal processing, identify the microwave pulse produced by the echo in the material surface.Correct echo signal recognition by intelligent software to complete, distance material on the surface of the distance D is proportional to the pulse of time travel T: D = C * T / 2 where C is the speed of light because of the distance of the empty cans E known, the level of L: L = E - D;

2, the output:

By entering empty cans height E (= zero), full tank height F (= full scale) and some applications to set parameters, application parameters will be automatically adapt instrument to measure the environment.Corresponding to the four...20 ma output;

3, measuring range:

F - measurement range;E - empty cans distance;B - the top blind area;H - probe zui small distance to the tank wall at the top of the blind area zui high material refers to material surface and measuring zui small distance between the reference point.At the bottom of the blind area is located near the bottom of the cable can't accurate measurement of the distance.At the top of the blind area and at the bottom of the blind area is effective measuring distance between;

4, note: only the material between the top blind area and at the bottom of the blind area, to guarantee the reliable tank level measurement.

Data processing:

By entering a empty cans height (L = zero), full fill height H (= full scale) and some applications to set parameters, application parameters will be automatically adapt instrument to measure the environment.4-20 ma is corresponding to the output.

Four, applications:

ZWRD700 series of guided wave radar level gauge is suitable for high temperature (350 ℃), high pressure, high vacuum, steam, dust and bad environment such as volatile gas.For continuous measurement of different materials.The instrument main technical indicators meet or exceed similar products at home and abroad, and convenient installation and debugging, can use a single, also can use network, can be widely used in metallurgy, building materials, energy, petrochemical, water conservancy, food and other industries.

Five, the main features:

1, strong commonality: measuring liquid level and material level, can satisfy the measurement requirements of different temperature, pressure, medium, zui high temperature is 800 ℃, zui up to 5 mpa pressure, and can be applied to negative situations, such as corrosion, impact.

2, prevent hanging: unique circuit design and the sensor structure, can make its measurement is not affected by sensor hanging, without regular cleaning, avoid measurement by mistake.

3, free maintenance: measurement process have no moving parts, no mechanical parts damaged problems, do not need to maintain.

4, anti-interference: non-contact measurement, anti-interference ability is strong, can overcome the steam, foam and mixing effect on the measurement.

5, accurate and reliable: measuring amount of diversification, makes the measurement more accurate, measurement is not affected by climate change, high stability, long service life.

Six, the technical parameters:

1, the working frequency: 100 MHZ - 1.8 GHz;

2, measuring range: cable type: 0-35 m pole type, coaxial type: 0-6 m;

3, repeatability, plus or minus 3 mm;

4, resolution: 1 mm;

5, sample: echo sampling/s 54 times;

6, the response speed: > 0.2 S (according to the specific use of the case may be);

7, precision: < 0.1%;

8, the output current signal: 4-20 ma;

9, communication interface: HART communication protocol;

10, process connection: G1-1/2, G3/4 flange: (, DN80, DN100, 6;

11, the process pressure: 1 ~ 60 bar;

12, power: 24 VDC ripple voltage (+ / - 10%) : 1 VPP;

13, power consumption: max22.5 mA;

14, environmental conditions: temperature: - 40 ℃ ~ 250 ℃;

15, shell protection grade: IP68;

16, explosion-proof level: EXiaIICT6;

17, two wire connection: instrument power supply and signal output sharing two core cable;

18, cable entry: M20 x 1.5 (cable diameter 5 ~ 9 mm).

Seven, installation instructions:

The following installation instructions applicable to bar type probe and cable type, tubular type probe measurement has nothing to do with the installation.

Location:

1, the distance of tank wall advice 1/6 - a quarter of the tank diameter (at least 300 mm, concrete tank at least 400 mm).

2, do not install in the middle of the metal cans;

3, don't pack the material mouth;

4, when choosing the length of the probe, pay attention to the bottom of the probe from the tank bottom is about more than 30 mm;

5, pay attention to the medium temperature.

Tank obstacles:

1, pay attention to when installation probe at least 200 mm away from the obstacle.

Remove interference:

1, clutter echo suppression: the software can realize the interference echo suppression, so as to achieve the ideal measurement effect;

2, the by-pass pipe and guided wave tube (only applicable to liquid) for viscosity don't play in the 500 CST, can adopt by-pass pipe, guided wave tube or pipe to avoid interference.

Liquid standard installation:

For 500 CST or less and not easy to produce the adhesive medium viscosity, tubular probe is an ideal scheme, its characteristics are as follows:

The reliability of the excellence;

1, can be used in any medium, dielectric constant is greater than or equal to 1.4 measurement has nothing to do with the conductivity of medium;

2, tank obstruction and short tube size does not affect the measurement;

3, than bar type probe can withstand the lateral pressure is high;

4, for the high viscosity of the medium, it is suggested that using bar type probe.

Lie the tank and the installation of vertical tank:

1, tube type probe and bar type probe zui to 6 meters long for tank measuring distance of more than 6 m, can choose 8 mm cable type probe;

2, installation and fixed measuring method with solid powder storehouse;

3, to the distance from the tank wall unlimited, as long as avoiding probe contact tank wall;

4, if the tank obstacles more or too close to the ground rod, please choose tube type probe.

Corrosive medium measurement:

1, if the corrosive medium, can choose lever probe sets a plastic casing was measured.

Eight, measuring condition note:

1, measurement range from the beam hitting a can of low starting point, but under special circumstances, if the tank is low for concave type or conical, when the level below this point cannot be measured.

2, if the medium to low dielectric constant when it is in low level, low visibility, at this time in order to ensure the accuracy of measurement, the recommendations will be zero at low altitude to the position of the C.

3, theory, measurement to achieve the position of the antenna tip is possible, but considering the corrosion and the influence of the adhesive, the final value of measuring range should be at least 100 mm distance from the tip of the antenna.

4, the overflow protection, additional on the blind spot can define a safe distance.

5, measurement range related to the antenna.

6, with different concentration, foam can absorb microwaves, and it can be reflected, but under certain conditions can be measured.

Nine, installation considerations:

1, as far as possible away from the discharging port and feed port.

2, to the metal cans and plastic cans, within the scope of the whole range don't go to the wall.If it is a metal cans, level instrument do not install in the middle of the tank.

3, advice, installed in a quarter of the diameter of the bunker.

4, cable type probe or bar type probe zui small distance from the tank wall not less than 30 cm.

5, probe at the bottom of the tank bottom about 30 mm.

6, the probe from the tank obstacles zui small distance not less than 200 mm.

7, if the container is at the bottom of the cone model, the sensor can be installed

8, roof, so that we can have been measured to the bottom.

Ten, the data table:

Table 1:

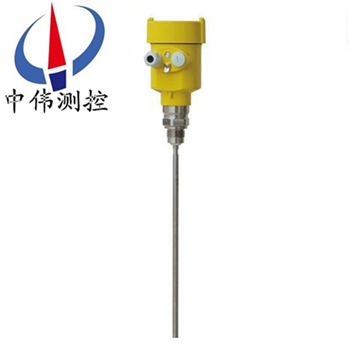

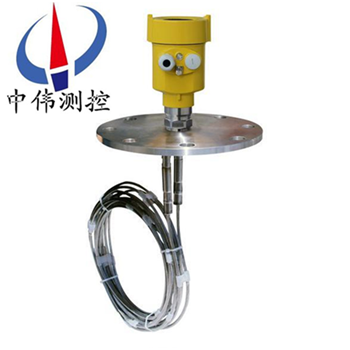

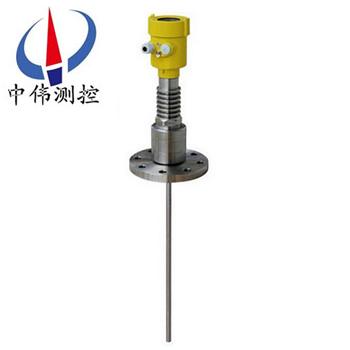

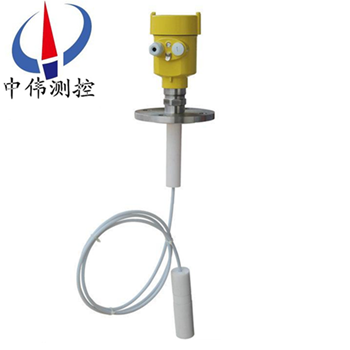

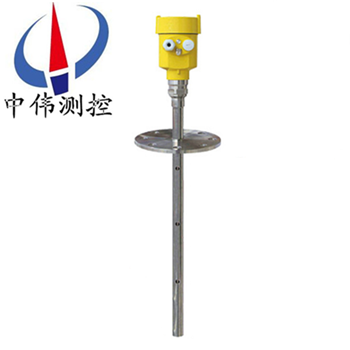

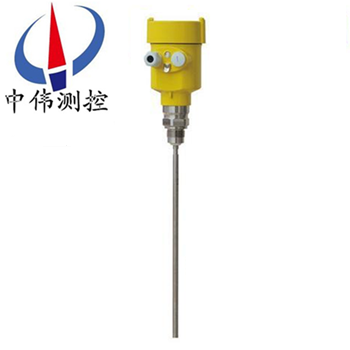

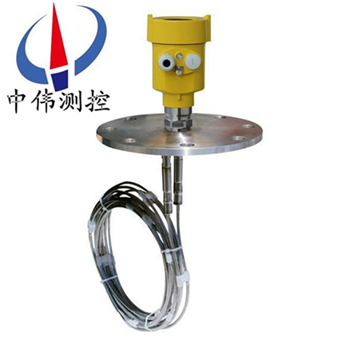

Product model | ZWRD701 | ZWRD702 | ZWRD703 |

Product pictures |  |  |  |

Range of application | For complex measurement, liquid and solid particle medium, large dust environment. | Suitable for solid and liquid medium Measurement, Powder particles medium. | Solid particles, liquid measurement and can be used for the relatively small dielectric constant of the liquid. |

Measuring range | 0 ~ 30m | 0 ~ 6m | 0 ~ 30m |

The connection method | Thread (G1-1/2″,1-1/2″NPTFlange (),DN50/80/100/150) | ||

Bin openings | Thread (Φ 40Flange (),(60 / Φ DN80 Φ 90 / DN100 Φ 110/6 Φ 160 mm) | ||

Working temperature | - 40 ~ 350℃ | ||

Pressure of work | -1.0~4.0MPa | ||

fine The degree of | 0.2%±1mm(at the top of the blind area500mm) | ||

miningsample | Echo sampling 55time/seconds | ||

Explosion-proof grade | EXiaIICT6/ExdIICT6 | ||

Protection grade | IP66 | ||

Signal output | The two lines4~20mA/HARTOr three line4~20mA | ||