High pressure type radar liquid level gauge

Products overview:

ZWRD805 seriesHigh pressure type radar liquid level gaugeWith a variety of forms and a variety of installation methods, suitable for almost all liquid (world) the measurement, can also be applied to the dust, flour, sand and granular material level measurement, can completely replace the buoy, the use of magnetic level gauge;It has many advantages, such as the measurement process, the measuring accuracy is not affected by medium density, temperature, pressure and other changes;And has a simple installation and debugging method, simply enter the configuration data can be used, it is a more advanced level instrument.

Second, the working principle:

ZWRD805 series high pressure type radar level meter is the measuring instrument based on the principle of time travel, very low energy is emitted by a very short microwave pulse by transmitting and receiving antenna system.Radar wave are running at the speed of light.Running time can be transformed into material level signal by electronic parts.Probe a high-frequency pulse and probe the conduction along the cable type or rod type, when the pulse in the material surface reflected by the receiver inside the instrument, and the distance signal is transformed into material level signal.A special type of time extension method can guarantee the stability of a very short period of time and accurate measurement.Even if the condition is relatively complex, false echo, adopt new micro processing technology and debug software can accurately analyze the level of the echo.

The input

Antenna receiving the reflected microwave pulse and sending them to the electronic circuit, microprocessor to signal processing, identify the micro pulse produced by the echo in the material surface.Correct echo signal recognition completed by intelligence software, precision can reach millimeter level.Distance on the surface of the material distance D is proportional to the pulse travel time T:

D=C×T/2

Where C is the speed of light

E known due to empty cans of distance, the level of L as follows:

L=E-D

The output

By entering empty cans height E (= zero), full tank height F (= full scale) and some applications to set parameters, application parameters will be automatically adapt instrument to measure the environment.Corresponding to the 4-20 ma output.

Applications:

ZWRD805 series high pressure type radar level gauge is suitable for high temperature (350 ℃), high pressure, high vacuum, steam, dust and bad environment such as volatile gas.For continuous measurement of different materials.The instrument main technical indicators meet or exceed similar products at home and abroad, and convenient installation and debugging, can use a single, also can use network, can be widely used in metallurgy, building materials, energy, petrochemical, water conservancy, food and other industries.

Four, the main features:

1, no blind area, high precision;

2, two wire system technology, it is the differential pressure instruments, magnetostriction, rf admittance, magnetic flap instrument of substitute products;

3, shall be subjected to pressure, vacuum, temperature changes, inert gas, dust, steam and other environmental impact;

4, installation is simple, durable, free maintenance;

5, the output signal is 4 ma ~ 20 ma/HART protocol, calibration is simple, through digital LCD easy calibration operation, by setting up and programming software to realize simple configuration;

6, measurement sensitivity, fast refresh;

7, suitable for high temperature working condition, process temperature up to 200 ℃, when high temperature to extend the antenna is used up to 350 ℃.

Five, the technical parameters:

1, the working frequency: 6.8 GHz;

2, measuring range: cable type: 0-35 m pole type, coaxial type: 0-6 m;

3, repeatability, plus or minus 3 mm;

4, resolution: 1 mm;

5, sample: echo sampling/s 54 times;

6, the response speed: > 0.2 S (according to the specific use of the case may be);

7, precision: < 0.1%;

8, the output current signal: 4-20 ma;

9, communication interface: HART communication protocol;

10, process connection: G1-1/2, G3/4 flange: (, DN80, DN100, 6;

11, the process pressure: 1 ~ 60 bar;

12, power: 24 VDC ripple voltage (+ / - 10%) : 1 VPP;

13, power consumption: max22.5 mA;

14, environmental conditions: temperature: - 40 ℃ ~ + 250 ℃;

15, shell protection grade: IP68;

16, explosion-proof level: EXiaIICT6;

17, two wire connection: instrument power supply and signal output sharing two core cable;

18, cable entry: M20 x 1.5 (cable diameter 5 ~ 9 mm).

Six, the daily inspection maintenance:

1, daily inspection maintenance mainly to check the power supply voltage and output current is normal.About 30 ~ 60 min after electrify, instrument can work normally.If there is no output parameter meter, should check whether the power supply is connected to real, and check whether the fuse is burnt.

2, when using is become an organic whole repeatedly and equipment, the whole system radar level meter is sealed, so at ordinary times should also check the sealing condition of joints of different parts are in good condition.

3, radar, head of the use of the internal temperature of 65 ℃.General use cases not more than the temperature, but if the temperature of the measured medium is very high, is the temperature inside the radar head could exceed 65 ℃.At this time, can use a small amount of wind, by the phi 6 x1 copper tube rain hat head blow in radar, to internal temperature down, never to do mechanical cooling water or other liquid.

4, volatile organic compounds in crystallization or antenna, radar level gauge trumpet to timely inspection and cleaning.

Seven, the debugging methods:

A, can through debugging in three ways:

1, by displaying the adjustment module PM;

2, through debugging software SOFT;

3, handheld programmer by HART.

B, through SOFT software debugging:

No matter the signal output, 4-20 ma/HART, radar sensors can be through the software debugging.Is instrument with the SOFT software debugging, need a meter CONNECTCAT drives.

Using software debugging, for the radar instrument 24 VDC power up, at the same time connect HART adapter front end with a resistance of 250 ohms.If the one-piece HART resistance (250 ohm internal resistance) of electricity meter, there is no need for additional external resistance, HART adapter can and 4...20 ma line in parallel.

Eight, measurement considerations:

1, measurement range from the beam hitting a can of low starting point, but under special circumstances, if the tank is low for concave type or conical, when the level below this point cannot be measured.

2, if the medium to low dielectric constant when it is in low level, low visibility, at this time in order to ensure the accuracy of measurement, the recommendations will be zero at low altitude to the position of the C.

3, theory, measurement to achieve the position of the antenna tip is possible, but considering the corrosion and the influence of the adhesive, the final value of measuring range should be at least 100 mm distance from the tip of the antenna.

4, the overflow protection, additional on the blind spot can define a safe distance.

5, measurement range related to the antenna.

6, with different concentration, foam can absorb microwaves, and it can be reflected, but under certain conditions can be measured.

7, measurement is beyond the scope of action when the measuring range beyond, instrument of 22 ma current output.

Nine, use requirements:

1, the installation location

Radar from the ideal location for the tank wall between radius of 1/2 to 1/3, away from the inlet port of discharge.If can not reach the ideal installation location selection radar level meter, I will try to choose more relaxed radar to installation position requirement.

2, dielectric properties

First is a solid, liquid, and medium point of dielectric constant, the greater the medium point of dielectric constant measurement radar effect, the better).Corrosion resistance, viscosity, etc.

3, the tank environment

A) good (tank without obstacles work when the environment is good).

(b) is bad there are obstacles such as mixing heating coils operating steam, crystallization, etc.).

Ten, parameter table:

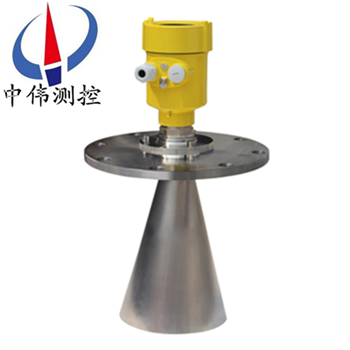

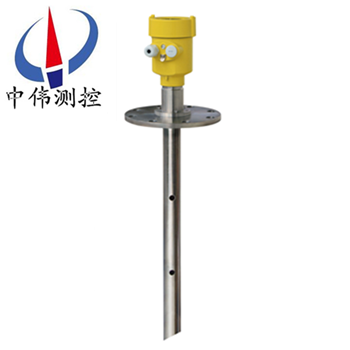

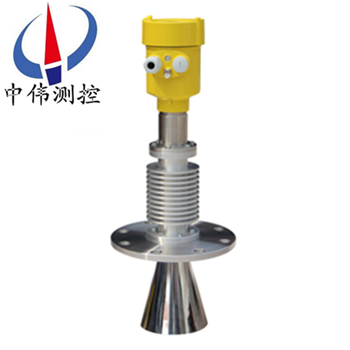

Product category | ZWRD804 | ZWRD805 | ZWRD806 |

Product pictures |  |  |  |

Range of application | Simple process conditions, granular material, block material | Low dielectric constant or mixing liquid | Environment of high temperature solid grain measurement |

measuring The amount van wai | 30m | 20M optional | 30m |

pass cheng evenPick up | Universal flange | The flange | The flange |

pass cheng wenThe degree of | - 40-250℃ | - 40-250℃ | - 40-250℃ |

pass chengpressure force | -1.0-3bar | -1.0-20bar | -1.0-40bar |

heavy after sex | ± 3mm | ± 3mm | ± 3mm |

fine The degree of | < 0.1% | < 0.1% | < 0.1% |

frequency The rate of van wai | 6.8GHz | 6.8GHz | 6.8GHz |

explosion-proof/Protection grade | EXiaIICT6/IP68 | EXiaIICT6/IP68 | EXiaIICT6/IP68 |

The letter No.Lose, Out of the | 4…20mA/HART(The two lines) | 4…20mA/HARTTwo lines) | 4…20mA/HART(The two lines) |

Eleven, selection of coding:

ZWRD805 | P | Standard (not explosion-proof) | explosion-proof | |||||||

I | The Ann model (Exia II CT6) | |||||||||

F | Flameproof (Exd II CT6) | |||||||||

A | PP/-40~80℃ | The antenna material/Working temperature | ||||||||

B | PTFE/-40~230℃ | |||||||||

1 | DN50 P1.6 | Flange specifications | ||||||||

2 | DN80 PN1.6 | |||||||||

3 | DN100 PN1.6 | |||||||||

4 | DN150 PN1.6 | |||||||||

1 | Carbon steel flange | Flange form | ||||||||

2 | Stainless steel flange | |||||||||

3 | PPFlanging flange | |||||||||

4 | PTFEFlanging flange | |||||||||

1 | There is no | Container to take over the length of | ||||||||

2 | 50mm | |||||||||

3 | 100mm | |||||||||

4 | 150mm | |||||||||

5 | 200mm | |||||||||

6 | According to the requirements of the user | |||||||||

Y | with | programmer | ||||||||

N | Don't take | |||||||||

1 | Two wire systemDC24V 4~20mA/HART | Connection mode | ||||||||

2 | Three wire systemDC24V 4~20mA | |||||||||

ZWRD805 | note | |||||||||