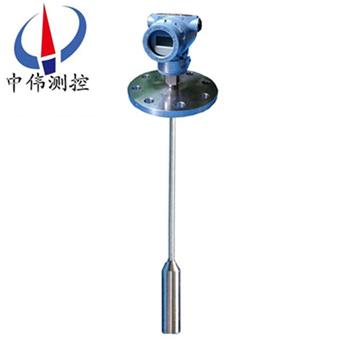

nsert stem type liquid level transmitter

Products overview:

ZW - DBS602 seriesInsert stem type liquid level transmitterVarious level changes of the parameters can be converted into a standard current signal, remote transmission to the operating room, for secondary instrument or computer for centralized display, alarm, or automatic control.Its good structure and installation, can be used in high temperature and high pressure, strong corrosion, easy to crystallization, prevent jams, prevent cold junction and under special conditions, such as solid powder, granular material level, material level or the level of continuous testing, which can be widely applied in all kinds of industrial process control testing.

Second, the working principle:

ZW series - DBS602 insert bar type liquid level transmitter for the principle of measurement of the electric field induction and to immersion agent changes the height of the measured medium, reflect the variation of induction frequency, the circuit transformation and the matching of 4 ~ 20 ma current signal output.Namely the calibration signal value generated by the CPC and operation on the signal value of measured medium and the difference is converted into a practical level.When the transmitter for people to a certain position in the liquid, feel the pressure sensor for: P = 9.80665 rho H

One P liquid pressure effect on the sensor, the unit kPa

Rho a liquid density, g/cm3

H a liquid level height under test, the unit m

So material 0 H.10197 p/p

To feel the pressure signal into electrical signal in the transmitter, the signal is proportional to the height of liquid.

Applications:

ZW series - DBS602 insert bar type liquid level transmitter its good structure and installation, can be used in high temperature and high pressure, strong corrosion, easy to crystallization, prevent jams, prevent cold junction and under special conditions, such as solid powder, granular material level, material level or the level of continuous testing, widely used in electric power, metallurgy, chemical industry, food, pharmaceutical and other industries, and sewage treatment, boiler steam drum, pulverized coal level measurement of packages and other places.

Four, the main features:

There were 1, simple structure, moving or elastic element, so stay on sex is extremely high, little maintenance.

2, easy installation, built in especially shows the characteristics of the structure, without any special tools.

3, easy to adjust, zero and span two potentiometer can be zero within the scope of the liquid level detection effectively any migration or range change, two adjustment each other.

4, wide range of USES: applicable to high temperature and high pressure, strong corrosive medium level measurement.

Five, the technical parameters:

1, the effective detection range: 0-0.2-20 m;

2, fine degree: 0.5, 1, 1.5 on the Richter scale;

3, pressure range: 32 mpa under negative pressure, normal pressure and high pressure;

4, work temperature: - 50 ~ 240 ℃;

5, environmental temperature: - 20 ~ 75 ℃;

6, suitable medium: acid, alkali, salt, or any of ptfe non-corrosive medium;

7, the output signal: 4-20 ma, two wire;

8, power supply, load resistance 0-750 Ω DC24V;

9, fixed way: thread M20 x 1.5, M27 x 2 flange installation DN15 and DN25, (and DN80;

10, the scene show: analog display 0-100%, digital display, depth of field.

Six, measurement system:

Measurement system for this type.

This safety type pressure, differential pressure transmitter adopts the intrinsically safe circuit, suitable for explosion-proof grade ExiallCT4 - CT6 explosion danger area.

Shielding signal cable must be used in the system circuit, and reliable grounding.Below are just 4-20 ma output signal and the measurement system of 0 to 10 ma, for example the wiring diagram,

Liquid level transmitter has reliable operation, stable performance, small volume, light weight, low cost, refined design, a variety of structural form, easy installation, without stents.Circuit board USES the microprocessor based electronic technology, can automatically eliminate the influence of temperature change on the sensor precision.

This series of products can be equipped with LCD liquid crystal display (LCD), to facilitate the local operation.

Intelligent output with HART communication function at the same time.

Seven, installation and commissioning:

Cable type and lever type liquid level transmitter has many installation fixed way, so as to adapt to different site conditions.When the site will not be able to provide M20 x 1.5 in the process facilities such as thread or the flange, can choose wall installation type, horizontal pipe frame and vertical posture, such as three optional installation way, make you comfortable when installation.

When measuring liquidity larger medium, to prevent violent oscillation sensor, the user can choose counterweight attachment, to have the effect of stable sensors, add weight must to put weight objects in the bottom of the container, in order to avoid pull bad sensing wires.

In the field environment is bad, the user should choose sensor shield to protect sensor, to avoid the foreign body damage or affect the accuracy of measurement.

Using ZW602 lever type liquid level transmitter, if not metal containers, you need to put the transmitter of the shell with a wire access the bottom of the container, otherwise not accurate measurement.

This product in the factory has a calibration, if need on-site adjustment can adopt the following methods:

A: using intelligent circuit debugging methods:

The zero -- -- -- -- -- - when the liquid level position is low, at the same time hold down the "Z" key and "S" key 8 seconds after release at the same time, then "Z" key press, the output current automatically adjusts to 4 ma.

Field adjustable full -- -- -- -- -- - when the liquid level high, at the same time hold down the "Z" key and "S" key 8 seconds after release at the same time, then the "S" key press, automatic adjustment to 20 ma output current.

B: adopting the method of analog circuit debugging:

When the liquid level in the next period, use the screwdriver slowly rotating "Z" potentiometer, observe the ammeter reading close to 4 ma.

When the liquid level in the limited time, use a screwdriver slow rotation "S" potentiometer, observe 20 ma current meter reading is close.

So above 2 to 3 times repeatedly, until zero and range are accurate 20 ma ma and 4, respectively.

After adjust, should tighten the lid of the transmitter.

Eight, installation and the matters needing attention:

Appearance and installation:

Liquid level transmitter consists of shell, amplifier, terminal blocks, helmets, hollow wire, etc, according to the needs of the user can choose a pointer table, LCD display meter.

Installation method:

1, choose easy to place for installation operation and maintenance;

2, shall be installed as far as possible away from the vibration source;

3, should be far away from heat source as far as possible;

4, the inputting type liquid level transmitter installation, metal probe to sink to the bottom of the container.

Note:

1, the supply of products with product certificate and instruction manual with the product serial number, technical parameters, wiring diagram, production date, etc. Please check carefully to avoid using wrong.

2, when installation should be according to the product connection and screw type, check the site interface is consistent with the product interface.For screw thread interface, should slow tightened, pay attention to the sealing, can't add the torque directly to the transmitter shell, can only add on the six-party transducer interface.

3, connection should be in strict accordance with the company I use for connection.

4, this product is a precision in instrument, banned free disassembly, collision, drop, play hard.

5, the transmitter power can work, but warm up 30 minutes output stability.

6, if discovery is unusual, in use should turn off the power and stop using, check, or directly to our technical department.

7 should be restored the original packaging, transportation, storage, stored in a cool, dry and ventilated warehouse.

8, installation and use process should pay attention to not put the induction of the skin of the wire broken.

9, when installation induction leads to at least more than 10 cm away from the pool wall, otherwise not accurate measurement.

10, all four fluorine structure and lever type level ground wire must be measured medium conduction, and measurements are not accurate.

11, installation site should take effective lightning protection measures.

12, the series of any liquid level transmitter enclosure must be reliable grounding, grounding resistance should be less than 4 Ω.

13, according to the security gate flame-proof certification, its installation should be according to the requirements of the specification.

14, when the transmitter is used to "0" zone, grid power supply to the safety of the power transformer shall meet the requirements of article 8.1 GB3836.4-2000.

Nine, selection of details:

1, indicate the measuring range (level of), for some special medium, indicate the density of the medium.

2, type selection, attention should be paid to contact with the product of the measured medium material compatibility, for special medium, can be customized.

More than 3, the product installation in the thunderstorm area, the order should be marked "lightning", recommend that users install against lightning protection device at the scene, and make sure products and power grounding.

4, about the selection of gas leading cable length: general than the actual level of 1 ~ 2 meters long.

Ten, selection of code:

Type spectrum | Said Ming | |||||||||

ZW-DBS60 | In the liquid level transmitter (wei measurement and control) | |||||||||

Class quality, | 1 | Sink into the cable type | ||||||||

2 | Insert the lever | |||||||||

Transmitter type | G | standard | ||||||||

D | Flameproof (Exd Ⅱ CT6 1 area including acetylene) | |||||||||

I | The Ann model (Exd Ⅱ CT4 1 area) | |||||||||

The process connection type | T | External thread connecting pipe M20 x 1.5 | ||||||||

F | Flange (0.6 MPa GP9119.6 PN - 88 | |||||||||

E | Flange DN100 PN 0.6 MPa GP9119.6-88 | |||||||||

S | M27 x 2 external thread | |||||||||

Y | The special requirements of contract | |||||||||

Containment requirements | 4 | Strong corrosion resistance | ||||||||

8 | Resistance to crystallization | |||||||||

Indicating meter | M1 | Pointer to the header | ||||||||

M2 | Digital display meter | |||||||||

Precision grade | 02 | 0.5% | ||||||||

05 | 1% | |||||||||

07 | 1.5% | |||||||||

-□ | The length (mm) | |||||||||

-□ | Liquid level range (mm) | |||||||||