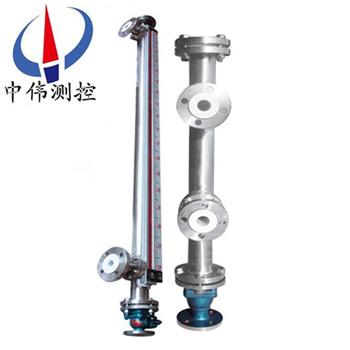

Side-mounted anticorrosive magnetic tilting plate level gauge

I. Product Overview:

ZW-UHZ series side-mounted anti-corrosion magnetic tilting plate level gauge is based on magnetic float as measuring element, magnet driving tilting column display, without energy. Suitable for low temperature to high temperature, vacuum to high pressure and other environments. It is an ideal liquid level measurement product for petroleum and chemical industries. With upper and lower limit switch output, remote alarm and limit control can be realized. With transmitter, liquid level can be indicated, detected and controlled at a long distance. Side loading and top loading are provided according to the location of the container. According to different working media, stainless steel and ABS engineering plastics are provided. ABS is especially suitable for corrosive media such as acid and alkali.

II. Working Principle:

1. Basic type

ZW-UHZ series side-mounted anti-corrosive magnetic tilting plate level gauge according to buoyancy principle, float moves up and down along with the rise and fall of liquid level in the measuring tube. The magnetic steel in the float drives the red and white tilting columns to turn 180'liquid level upward by magnetic coupling. When the tilting columns turn from white to red, and when they fall, the tilting columns turn from red to white, thus realizing the liquid level indication.

2. Upper and Lower Limit Switch Output

The magnetic float moves with the liquid displacement to make the switching action on the setting position of the riser of the liquid level gauge to realize on-off control or alarm.

3. Teletransmission

A transmitter is installed on the magnetic tilting plate level gauge. The transmitter consists of two parts: sensor and converter. It moves up and down through magnetic float. Through magnetic coupling, the measuring elements in the catheter act in turn, and the resistance signal is changed. The standard current signal output of 0-10 or 4-20 mA is summoned to connect with digital display instrument or computer to realize remote display and control.

3. Application occasions:

ZW-UHZ series side-mounted anti-corrosion magnetic plate level gauges are widely used in various kinds of liquid storage tanks, tanks, liquid storage tanks, reaction tanks, fermentation tanks, oilfields, liquefied gas, liquid hydrogen, strong acid and alkali liquids, weak acid and alkali liquids, power plant boiler drums, high and low addition, deaerator, drainage tank, high and low pressure heater of water return tank, condensation tank and so on. The liquid level, liquid level and interface between 1Cr8NitTi, 304+PTEE (polytetrafluoroethylene), 316L, PVC and PP compatible liquid media in main and other pressure vessels are measured and displayed.

Fourth, main characteristics:

1. The design is simple, compact, solid and reliable, long life, no maintenance workload can be long-term outdoor installation and use;

2. The measuring tube is completely separated from the liquid level display part, the liquid level transmitter and the alarm switch in terms of pressure and air resistance.

3. Working pressure range is wide, withstanding pressure from vacuum to 42 MPa.

4. Wide working temperature range, suitable for - 160 - 450 C.

5. Widely used for measuring liquid level of strong or weak corrosiveness, flammability, explosiveness, toxicity, strong radioactivity, agitation and dirty.

6. Dingyou magnetic alarm switch can be selected for each type to realize automatic control or alarm of high and low liquid level.

7. All models can be equipped with 4-20 mADC liquid level transmitter to realize remote centralized measurement and control.

Technical parameters:

1. Measuring range: 300-5000_ (special customization over 5000mm);

2. Display accuracy: +10 mm;

3. Working pressure: PTFE of stainless steel lining: <2.5 MPa;

Stainless steel liner PP: <1.0Mpa;

(Pressure can be 25 Mpa. See Instruments of High Temperature and High Pressure Type for details)

4. Medium temperature: stainless steel liner PTFE: -20-200 C;

Stainless steel lining PP:-20-90 C;

5. Medium density: > 0.5g/cm3;

6. Media density difference: > 0.15g/cm3 (measurement boundary)

7. Medium Viscosity: <0.4Pa.S;

8. Process Connection: DN20/25 PN1.0 (implementation standard HG20592-20635-97), other standards can be manufactured according to customer requirements.

9. Material of liquid connection: PTFE, PP; (according to the chemical properties of medium and the temperature and pressure of use);

10. Float material: PTFE, PP, stainless steel liner PTFE, etc.

6. Additional Functional Options:

1. Magnetic limit switch:

Normally open type: merge above alarm point;

Normally closed type: disconnection above alarm point;

Switching capacity: 250VAC1A (resistance) 250VAC0.3A;

Switch life: 100000 times.

2. Level transmitter:

Output current: 4-20 mADC;

Resolution: +1-+10 mm;

Load resistance: 500_ (24VDC power supply);

Transmission distance: > 3000m;

Working power supply: 16-30 VDC.

3. Intelligent level transmitter:

Output current: 4-20ADC;

Resolution: 0.2mm;

Load resistance: 500_ (24VDC power supply);

Transmission distance: > 3000m;

Working power supply: 16-30 VDC.

Classification and application:

1. Inserted magnetic tilting plate level gauge: This level gauge is suitable for measuring and controlling the level of underground tanks and pools.

2. Thermal insulating magnetic turning plate level gauge: The level gauge is a heat insulating jacket installed outside the main body of the basic type to form heat media such as steam. The normal flow of liquid in the main body can be maintained. Therefore, it is suitable for liquid level measurement and control of easily solidified liquids. For low boiling point liquids, refrigerants such as cold water can be introduced to ensure the stability of liquid level. Make the instrument indicate the measured liquid level correctly.

3. Frost-proof magnetic turning plate level gauge: It is a product specially designed by our factory to solve the freezing outside the cryogenic liquid level gauge. Inside the insulation jacket is a vacuum layer. Therefore, it can effectively isolate cold and heat conduction. It ensures that the outside of the main pipe of the level gauge will not freeze or frost. This ensures the normal use of the level gauge.

4. Strong corrosion resistant magnetic turning plate level gauge: All parts of the level gauge in contact with the medium are made of steel-plastic composite pipes. All liquid level measurements and controls suitable for various strongly corrosive media