Double flange differential pressure diaphragm liquid level transmitter

Products overview:

ZW3851LDP seriesDouble flange differential pressure diaphragm liquid level transmitterIs a remote transmission device on a pipe or container to feel the pressure, the pressure inside by capillary pump silicone oil (or other liquid) to the body of the transmitter, then the transmitter inside the body and amplification circuit board, converting pressure or differential pressure into 4-20 ma.Dc signal output.Far eastone pressure, differential pressure transmitter and combination of intelligence amplification board, can constitute a smart remote transmission pressure, differential pressure transmitter, and conform to the HART protocol with the hand of the operator, can communicate, to set up and monitor.In order to adapt to different installation requirements, this series transmitter has many forms of remote transmission device for the user to choose from, main body structure and differential pressure transmitter, the pressure transmitter is the same.

Can accurately measure differential pressure, and converts it into DC4 ~ 20 ma output signal.The transducer adopted by micro processing technology made of silicon micro capacitive sensor and microprocessor, has excellent features and functions, small, lightweight, good environmental adaptability, applicable to all areas.If use handheld communication device (sold separately), through remote operations, in does not affect the transmitter DC4 ~ 20 ma output signal at the same time, for display and setting.

Second, the working principle:

ZW3851LDP series double flange diaphragm measurement principle of differential pressure level transmitter is when two of the measured medium pressure ventilation with high and low pressure chamber, two functions in the delta components (i.e., sensitive element) on either side of the segregation on the diaphragm, through spacer and components on both sides of the filling liquid to measure the diaphragm.Liquid level transmitter is by measuring diaphragm and on both sides of the insulation on the electrodes of a capacitor.When we have different pressure on both sides, to cause measuring diaphragm displacement, the displacement and stress is directly proportional to the difference, so both sides capacitance range, through the link of oscillation and demodulation, is converted into is proportional to the pressure signal.

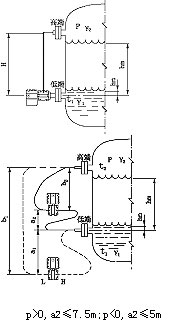

JiYiDuan allowed pressure liquid, the other end songs in phase, according to the principle of hydrostatics, are:

PB = PA + H rho g (2-1)

Type: H - liquid height;

Rho - density measured medium;

G - measured the local acceleration of gravity.

By type (2-1) available:

Δ P = PB - PA = H rho g

In general, the density of the measured medium and the acceleration of gravity is known, as a result, the differential pressure gauge measured the differential is proportional to the liquid height H, thus the measurement of the altitude of the liquid into the measurement of differential pressure problems.

Three, double flange level transmitter measuring liquid level diagram:

Four, applications:

ZW3851LDP series double flange differential pressure diaphragm liquid level transmitter can avoid direct contact and transmitter isolation diaphragm measured medium, this method is applicable to the following several ways:

1, the sensitive element of transmitter measured medium corrosion were role;

2, need to be measured medium and high temperature transmitter isolation;

3, the measured medium has suspended solids or high viscosity medium;

4, the medium to be tested by the lead pipe at the same time easy to curing or crystal;

5, change must strictly to purify the measuring head measured medium;

6, measuring head must keep health, it is forbidden to pollution.Using the object: corrosive or viscous liquid.

Note: vacuum circumstance unfavorable use remote transmitter.

Five, the main features:

1, the super performance measurement for pressure, differential pressure, liquid level, flow measurement;

2, digital precision: + (-) 0.05%;

3, the simulation precision: + + (-) (-) 0.75% 0.1% F.S;

4, the whole performance: + 0.25 F.S (-);

5, stability: 0.25% 60 months;

6, span ratio: 100:1;

7, volume rate: 0.2 S;

8, miniaturization (2.4 kg) stainless steel flange, easy to install;

9, process connection compatible with other products, the realization of ideal measurement;

10, with H alloy sheath of sensors (technology), and achieved excellent cold and hot stability;

11, using 16 computer intelligent transmitter;

12, standard 4-20 ma, with digital signal based on HART protocol, remote control;

13, support to the field bus and upgrade based on the technology of field control;

Six, the technical parameters:

Output signals: 4 ~ 20 ma DC two wire (simulated)

Two wire 4 ~ 20 ma digital signal superimposed on the dc signal, the linear output or prescribing selected by the user.(smart);

Power supply: 12 ~ 45 v DC;

Power supply: < 0.005% output range/V;

14, to avoid directly measured medium in transmitter isolation diaphragm contact provides a reliable measuring method;

Resistance, : usually can be adjustable between 0.1 ~ 16 seconds, when the pump inert liquid or remote transmission device, the time constant will increase;

Start time: < 2 seconds, without preheating;

Working environment: the environment temperature - 29 ~ 93 ℃ (analog amplifier);

- 29 ~ 75 ℃ (digital/intelligent amplifier);

- 29 ~ 65 ℃ (with display meter);

Environmental humidity 0 ~ 95%;

Protective features: protection IP65;

Explosion-proof type, flameproof Exd II BT4-6;

The Ann model Exia CT5 II;

Static effects: zero error: plus or minus 0.5% z limit value in a wide range, for 32 mpa in the pipes under pressure by zero correction;

Electromagnetic radiation effects: 0.05% z value in a wide range, accept radiation frequency 27 ~ 500 MHZ, experimental field 3 v/m;

Indicator (%) : LCD digital display precision of + / - 0.2%;

200 hz vibration impact: any direction vibration, plus or minus 0.05% / g;

Installation location: diaphragm is not installed vertically, the zero error of less than 0.24 KPa may be produced, but can be modified by zero;

Weight: 3.9 Kg (not including attachments).

With remote transmission device, liquid level transmitter is applicable to the following conditions:

1, you need to high temperature medium from the transmitter.

2, corrosion transmitter sensitive element for measuring medium.

3, due to environment or measured medium temperature change and solidifying or crystallization.

4, replace the measured medium need strictly to purify the measuring head.

5, suspending liquid or high viscosity medium.

6, measuring head must maintain clean sanitation.

7, sealing pressure container.

Eight, matters needing attention and routine maintenance:

1, using a new double flange differential pressure transmitter, to check the flange in the diaphragm liquid adequacy (how many of each production electrode internal charging different requirements), such as too little, should be returned to the factory maintenance.

2, for never immersed in solution of diaphragm and dry on the sensor for a long time, before use to need to look at is damaged, the purpose is to make after compression, sensor diaphragm rupture, causing the oil mixed with measuring medium.

3, daily use flange removal should be used when not in use cases, avoid by all means will be diaphragm bare outside.

4, need not can do put for a long time, often use zui good save in the fluid of the electrode to protect, but to soak activated before use.

5, measurement of acid alkali will greatly reduce the electrode life, so if you need frequent measurement of acid alkali zui good special acid alkali resistant diaphragm of choose and buy.

6, membrane cleaning water, water should not be too big, do not use scrubbing brush iron or other metal.

7, flange to should take put down gently, the diaphragm is very fragile, so as not to knock against.

Nine, selection considerations:

1, the model selection according to specification table according to the need to make sure.

2, selection of specifications in the table Numbers, symbols must be fill in clear, accurate.

3, if you have positive and negative migration, must indicate the migration amount value.

4, differential pressure transmitter to match three valve group, need to be indicated separately.

5, when far eastone transmitter of choose and buy, should also be based on different remote flange selection table according to the need to be sure.

6, if the remote transmitter should be used in vacuum and high temperature occasion, special label when you order.

7, contact medium type O sealing ring material is rubber, fluorine rubber, etc.

8, no special note, the factory when the liquid silicone oil.

Ten, selection of code:

Manufacturers specifications | Code instructions | |||||

ZW3851LDP | Double flanged diaphragm differential pressure level transmitter (in wei and control) | |||||

code | Scale rangeKPa | |||||

3 | 0-1.3~ 7.5 | |||||

4 | 0-6.2~37.4 | |||||

5 | 0-31.1~186.8 | |||||

6 | 0-117.~690 | |||||

7 | 0-345.~2068 | |||||

8 | 0-117.~690 | |||||

code | The output | |||||

E | 4-20mADC | |||||

S | Intelligent type | |||||

Code name | The flange material | The flange material | ||||

22 | 316SST | 316SST | ||||

Code name | Additional features | |||||

S1 | A remote device | |||||

S2 | Two remote transmission device | |||||

code | options | |||||

M1 | 0-100%Linear indicator | |||||

M2 | LEDAccording to the table | |||||

M3 | LCDAccording to the table | |||||

B1 | Bend tubes of stents | |||||

B2 | Plate bending bracket | |||||

B3 | Pipe bracket with flat | |||||

d | flameproofdⅡBT4 | |||||

i | The Ann modeliaCT6 | |||||

Eleven, design selection and ordering information:

1, working pressure also depends on the selection of the specifications of the flange.

2, remote transmission device working temperature, the choice of types of liquid filling.

3, far eastone pressure transmitter is one side of the remote device by temperature effect, the output generated by the change.