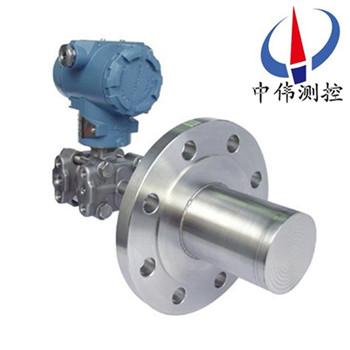

Single flange level transmitter

Products overview:

ZW3051LTC seriesSingle flange level transmitterIs the introduction of foreign advanced technology and equipment production of new type of transducer, the key raw materials, components and parts are imported, the whole machine after assembled and tested strictly, this product has the advanced design principle, the variety specification is complete, installation convenient use, etc.Due to the aircraft appearance on the total integration of the current domestic zui is popular, and widely used two kinds of transducer (3051 with yokogawa EJA rosemount) the structure of the advantages, for the users to have the feeling that find everything new and fresh, at the same time with the traditional series of products can be directly replace on installation, strong commonality and replace ability.For the continuous improvement of the domestic automation level and the development, this series of products in addition to the design cabinet and delicate, more has introduced HART field bus protocol of intelligent function.

Second, the working principle:

ZW3051LTC series single insert flange level transmitter is made up of intelligent transducer with capillary with stainless steel flange connection, is a kind of by installing remote transmission device on a pipe or container to feel the pressure, the pressure inside by capillary pump silicone oil (or other liquid) to the body of the transmitter, then the transmitter inside the main body of the delta and amplification circuit board, to convert pressure or differential pressure 4 ~ 20 ma. DC signal output, and conform to the HART protocol with the hand of the operator, can communicate, to set up and monitor.

Applications:

ZW3051LTC seriesSingle flange level transmitter is used to prevent the pipe pressure sensor components in the medium directly into the transmitter, it is between the transmitter and capillary connected by the filled with fluid.Used to measure liquid, gas or liquid level, flow and pressure of steam, then transform it into a 4 ~ 20 ma DC signal output.Applicable medium is as follows:

1, high temperature viscous medium;

2, easy to be crystallized media;

3, with solid particles or suspended solids precipitation medium;

4, strong corrosive or toxic medium;

5, can eliminate the occurrence of pressure pipe leakage pollution environment;Using spacer can be avoided, because of the measuring signal is not stable, often need to supplement of spacer;

6, continuous accurate measurement interface and density;

7, remote transmission device can avoid different instant media fusion, so that the measured results truly reflect the actual situation of process changes;

8, hygiene demanding situations;

9, such as food, beverage and pharmaceutical industry production, not only requires the transmitter medium contact conform to the hygiene standards, and should be easy to wash, to prevent cross contamination of different mass media.

Four, the main features:

1, indicating novel, intuitive reading and eye-catching, observing the direction of the indicator can be based on user need to change the point of view.

There were 2, simple structure, moving or elastic element, so stay on sex is extremely high, little maintenance.

3, installation is convenient, built in especially shows the characteristics of the structure, without any special tools.

4, easy to adjust, zero and span two potentiometer can be zero within the scope of the liquid level detection effectively any migration or range change, two adjustment each other.

5, wide range of USES;Suitable for high temperature and high pressure, strong corrosive medium level measurement.

6, large measuring range, not restricted by storage tank height.

7, indicating device, and is completely isolated measured medium, good sealing, high reliability, the use of safe.

8, have the ability to safety explosion protection and isolation and can be applied to all kinds of dangerous sites.

9, with anti blocking design can be realized to paste medium level measurement.

10, fine unique zero, full range, nonlinear compensation, guarantee conditions of use within the scope of the precision, good stability for a long time.

Five, the technical parameters:

1, the output signal: 4 ~ 20 ma DC two wire (simulated) two wire 4 ~ 20 ma digital signal superimposed on the DC signal, the linear output or prescribing selected by the user.(smart)

2, power supply: 12 ~ 45 v DC;

3, load characteristics:

Power supply: < 0.005% output range/V;

Load impact: when power supply stable, without load effect;

Accuracy of measurement, calibration range of plus or minus 0.1%, plus or minus 0.2 standard accuracy is + / - 0.2%, if choose other precision in the model selection of the order, please specify;

Quantity than: now or 100-1;

Resistance, : usually can be adjustable between 0.1 ~ 16 seconds, when the pump inert liquid or remote transmission device, the time constant will increase;

Start time: < 2 seconds, do not need to preheat.

4, work environment: the environment temperature - 29 ~ 93 ℃ (analog amplifier);

29 ~ 75 ℃ (digital/intelligent amplifier);

- 29 ~ 65 ℃ (with display meter);

Environmental humidity 0 ~ 95%.

5, protective features: protection IP65;

6, explosion-proof type, flameproof Exd II BT4-6;

The Ann model Exia II CT5.

7, static pressure influence: zero error: plus or minus 0.5% zui limit, in a wide range for 32 mpa in the pipes under pressure by zero calibration.

Zui 8, the electromagnetic radiation: 0.05% value in a wide range, accept radiation frequency 27 ~ 500 MHZ, test voltage 3 v/m.

9, indicator (%) : LCD digital display accuracy + / - 0.2%.

200 hz, vibration impact: any direction vibration, plus or minus 0.05% / g.

11, installation location: diaphragm installed vertically, not likely to produce the zero error of less than 0.24 KPa, but can be modified by zero.

12, heavy volume: 3.9 Kg (not including attachments).

Six, maintenance procedures:

1, the structure:

Single flange level transmitter by differential pressure transmitter, capillary and belt of flange seal diaphragm.Seal diaphragm role is to prevent the pipe in the medium directly into the differential pressure transmitter, it is between the transmitter and by filling of liquid (usually use silicone oil) capillary connected, when diaphragm pressure to produce tiny deformation, deformation or frequency through capillary liquid is passed to the transmitter, the transmitter converts the output signal after processing.

2, appearance inspection:

A, flange check: check the flange connected to the equipment section of the seal are in good condition;Flange and capillary, capillary and itself if there is a connection part of the transmitter and capillary liquid leakage;Flange diaphragm deformation, damage, corrosion, scaling and other adverse conditions.

B, the transmitter inspection: check whether there is any damage, corrosion and other failure on transmitter shell, handle in time when problems found.

3, acceptance:

A, open the cover in the transmitter, check the sealing ring is damaged, if the damage to change in time;Check the circuit boards and other components are in good condition.

B, check the wiring of transmitter are in good condition.

C, disconnect the power supply, wire, insulation resistance checks, with a 500 v megohmmeter check transmitter terminals and shell, the insulation resistance between the resistance value should be greater than 20 m above.

4, single flange level transmitter to debug the check

In order to ensure that a measuring precision of the single flange level transmitter transmitter, cannot open capillary, so check to check with flange transmitter;Before installation, can use pneumatic analog signals and calibrate the HART com.

B, zero and span adjustment steps: zero and range of output, so that it is within the scope of permissible error.Continuous pressure, with the range of 0%, 25%, 50%, 75%, 150% of the pressure calibration, when pressure is stable after the record on the standard ammeter displays the current value and do return error checking.If calibration error exceeds permissible error range, should readjust the check.Adjusting method when operated by HART, see HART instructions accordingly.

4, installation:

A, far eastone flange installation:

High and low pressure on both sides of the flange should be installed correctly, can't put wrong;To reduce the influence of environment temperature difference, can be high and low voltage side of capillary bundle together, and fixed to prevent the wind and the influence of vibration and so on (super long section of the capillary volume in fixed together).Be careful not to damage the surface of the liquid membrane.Don't distort, extrusion capillary, don't put too much pressure to it.

B, the installation of transmitter ontology: use the installation bracket, the transmitter ontology is installed on the pipe diameter of 50 mm.Can be installed in horizontal pipe and the vertical piping installation.

5, note:

A, the four bolts fastening measuring capacitance room, connecting the capillary and let room part of the set screw absolutely not loose, liquid sealed to prevent leakage and instrument damage.

B, wiring should avoid large capacity transformer, motor or power with power interference sources;Wiring should disconnect the power supply interface of dustproof plug;Thread department should undertake waterproof treatment (waterproof zui good use when not hardened silicone sealant series);To prevent interference, and other signal cable should avoid power cable through the same cable protection tube;For explosion-proof type instrument, in order to ensure the explosion-proof performance, must be in accordance with the relevant provisions of the wiring.

Seven, maintenance:

The following is our maintenance of single flange level transmitter is introduced.

1, flange level transmitter occurred during the winter freeze, when installed in the outdoor anti-freezing measures needed for transmitter, without pressure, fluid due to the icing volume expansion in the mouth, lead to the damage of sensors.

2, connection, cable through the waterproof connector (attachment) or round tube and screw down the sealing nut, such as in case of rain through the cable leakage into the transmitter inside the shell.

3, when measuring the pressure of the gas, apply pressure to open at the top of the process piping, flange level transmitter and also will be installed in the upper part of the process pipe so that the deposition of liquid pipelines of rapid injection to the process.

4, single flange level transmitter measuring steam or other high temperature medium, the need to connect with the buffer tube (coil) such as condenser, should not make the transmitter operating temperature more than limit.

5, single flange level transmitter to pay attention to the guide of sensor pressure tube to install where small temperature fluctuations.

6, when measuring the liquid pressure, flange level transmitter installation location should avoid the impact of the fluid (water hammer), in order to avoid the sensor damage of overpressure.

7, single flange level transmitter in measuring the liquid pressure, the pressure mouth should be open in the process piping side, in order to avoid precipitation product residue.

8, to prevent fluid of flange transmitter and corrosive or overheating of media contact, prevent the dross in intraductal deposition.

Eight, flange level transmitter application process matters:

1, measure the liquid pressure, flange level transmitter installation location should avoid the impact of the fluid (water hammer), in order to avoid the sensor damage of overpressure.

2, when the winter freezing in single flange level transmitter, anti-freezing measures according to the required in outdoor transmitter, without pressure, fluid due to the icing volume expansion in the mouth, lead to the damage of sensors.

3, connection, cable through the waterproof connector (attachment) or round tube and screw down the sealing nut, such as in case of rain through the cable leakage into the transmitter inside the shell.

4, when measuring the liquid pressure, pressure pipe side should be open in the process, in order to avoid precipitation product residue.

5, to prevent fluid of flange transmitter and corrosive or overheating of media contact, prevent the dross in intraductal deposit;

6, when measuring the pressure of gas, pressure mouth will open at the top of the process piping, flange level transmitter and also will be installed in the upper part of the process pipe so that the deposition of liquid pipelines of rapid injection to the process.

7, to pay attention to the guide of sensor pressure tube to install where small temperature fluctuations;

8, measuring, steam or other high temperature medium to connect with the buffer tube (coil) such as condenser, should not make the transmitter operating temperature more than limit.

Nine,Selection of code:

ZW3051LTC | Single flange level transmitter (work pressure2.5MPaWei measurement in) (the) | |||||||||

code | Scale range | |||||||||

3 | 0-1.3~7.5KPa | |||||||||

4 | 0-4-40KPa | |||||||||

5 | 0 to 40~200KPa | |||||||||

6 | 0-0.16KPa~1MPa | |||||||||

code | The output | |||||||||

E | 4-20mA | |||||||||

S | Intelligent typeHARTagreement | |||||||||

code | Nominal diameter sizemm | Insert tube lengthmm | High side diaphragm material | |||||||

A0 | 3"80 | flat | 316LSST | |||||||

A2 | 3"80 | 50 | 316LSST | |||||||

A4 | 3"80 | 100 | 316LSST | |||||||

A6 | 3"80 | 150 | 316LSST | |||||||

B0 | 4"100 | flat | 316LSST | |||||||

B2 | 4"100 | 50 | 316LSST | |||||||

B4 | 4"100 | 100 | 316LSST | |||||||

B6 | 4"100 | 150 | 316LSST | |||||||

C0 | 3"80 | flat | hartzC-276 | |||||||

C2 | 3"80 | 50 | hartzC-276 | |||||||

C4 | 3"80 | 100 | hartzC-276 | |||||||

C6 | 3"80 | 150 | hartzC-276 | |||||||

D0 | 4"100 | flat | hartzC-276 | |||||||

D2 | 4"100 | 50 | hartzC-276 | |||||||

D4 | 4"100 | 100 | hartzC-276 | |||||||

D6 | 4"100 | 150 | hartzC-276 | |||||||

E0 | 3"80 | flat | tantalum | |||||||

F0 | 4"100 | flat | tantalum | |||||||

code | Installation of flange | |||||||||

A | 3"150lb | |||||||||

B | 4"150lb | |||||||||

C | 3"300lb | |||||||||

D | 4"300lb | |||||||||

code | " constitutive material material | |||||||||

Flange and joint | exhaust/The drain valve | Isolation diaphragm | Pump the liquid | |||||||

22 | 316Stainless steel | 316Stainless steel | 316Stainless steel | Silicone oil | ||||||

23 | 316Stainless steel | 316Stainless steel | Hartz alloyC | |||||||

24 | 316Stainless steel | 316Stainless steel | monel | |||||||

25 | 316Stainless steel | 316Stainless steel | tantalum | |||||||

33 | Hartz alloyC | Hartz alloyC | Hartz alloyC | |||||||

35 | Hartz alloyC | Hartz alloyC | tantalum | |||||||

code | options | |||||||||

M1 | 0-100%Linear indicator | |||||||||

M3 | 3One and a halfLCDAccording to the table | |||||||||

M4 | Intelligent table shows | |||||||||

B1 | Bend tubes of stents | |||||||||

B2 | Plate bending bracket | |||||||||

B3 | Pipe bracket with flat | |||||||||

D1 | The upper side discharge valve in the pressure chamber | |||||||||

D2 | Lateral release valve at the bottom of the pressure chamber | |||||||||

Don't note | 1/2NPTTaper pipe nipple | |||||||||

C2 | Jump nippleM20×1.5After, The weldingФ 14 System pressure tube ball cone head | |||||||||

d | flameproofdⅡBT4 | |||||||||

i | The Ann modeliaⅡCT6 | |||||||||