Wedge flowmeter

Products overview:

ZW - LGX seriesWedge flowmeterIs a new type of throttle differential pressure type flow measuring instrument, it can be in high viscosity, low Reynolds number, Reynolds number, 500 can use fluid to flow measurement with high resolution, small in low flow velocity, flow rate, pipe diameter of the flow measurement occasions have incomparable advantages and irreplaceable role.This meter has simple structure, no moving parts, not easy to be fluid wear, working performance is stable, reliable, long service life.The measuring element and take pressure device structure through without special fluids stranded or clog small pressure loss under the condition of the low Reynolds number is ideal for high precision flow measurement.

Second, the working principle:

ZW - LGX seriesWedge flowmeter is a differentia pressure type flow meter, it is the use of energy transformation in the airtight pipeline Bernoulli's law, namely: the steady fluid situations, of the pipeline flow rate is proportional to the square root of the differential pressure.Wedge flowmeter is in the eighty s began gradually to the utility of a new type of flowmeter, the test piece is a v-shaped wedge (also called wedge throttling), its sleek apex Angle downwards, so conducive to containing suspended particles of liquid or viscous liquid pass, not stagnation in throttling upstream side.Fluid flow through the wedge timing, due to the effect of the throttling of the wedge, on top of it, the downstream side produced a square with flow value differential pressure, the differential pressure from the wedge take pressure on both sides to the differential pressure transmitter into electrical signal output, then through special operations, intelligent flow totalizer.especially can show flow value.

Flow equation:

Type of qv - volume flowmeter, m3 / s

C -- -- -- -- -- - outflow coefficient;

Epsilon -- -- -- -- -- to expansion coefficient;

M -- -- -- -- -- - throttling area ratio;

D -- -- -- -- -- - pipe diameter, m;

Delta p -- -- -- -- -- - differential pressure, pa.

Rho -- -- -- -- -- - density measured medium, kg/m3

Wedge flow sensor has a discharge coefficient changes, temperature, density, nonlinear error correction function parameters, such as;Measuring accuracy can reach 0.5%;Can be the scene display and standard current output signal (4 ~ 20 ma DC), or can be conveniently used in automatic control system and computer networking, traffic or other parameters automatic adjustment and control.

Applications:

ZW series - LGX wedge flowmeter can be in high viscosity, low Reynolds number, Reynolds number > 500 can be used) of the fluid for high accuracy of flow measurement;Mainly used for high viscosity (heavy oil, residual oil, diesel oil, engine oil, etc.), industrial gas, coke oven gas, blast furnace gas and producer gas, city gas), hydrogen, nitrogen, air, water and sewage flow measurement of liquid such as medium.Measured medium is as follows:

1, gas,

Gas, natural gas, including high moisture of natural gas and other impurities clean gas.Air, including water, containing solid particles and other air suspension.

2, steam

Saturated steam and superheated steam.

3, liquid

Oils, including crude oil, fuel oil, coal tar, residual oil, paraffin oil, emulsified oil, water cut, water cut oil containing sand, etc.Slurry, including slurry oil, iron ore pulp, pulp, slurry, coal slurry, etc.Water, including water purification, sewage, industrial wastewater, including sediment and sundry Jiang Heyuan water etc.All kinds of aqueous solution, including strong corrosion of all kinds of acid, alkali, salt solution and solution more easily crystallized, containing suspended solids.

Four, the main features:

1, particularly suitable for high viscosity, low Reynolds number, suspended particles or bubble medium measurement;

2, the measurement precision is not affected by fluid medium dielectric constant features of and restrictions;

3, wedge a special structural design, has guide effect, anti clogging;

4, the density of fluid viscosity, temperature changes, changes and other compensation function;

5, vibration resistance, impact resistance, resistance to dirt, corrosion, explosion-proof;

6, wedge flowmeter has two-way flow measurement function;

7, high measuring accuracy;

8, simple structure, strong, high reliability, convenient installation and operation maintenance cost is low

9, no moving parts, no wear, use for a long time do not need to calibration.

Five, the other features:

1, suitable for measuring the mud, coal tar, coal water slurry and other high viscosity fluid;

2, under the condition of low pipe Reynolds number (even low to Re = 500), stays a square root relationship between flow rate and differential pressure.The orifice meter zui to measurement of small Reynolds number are much larger than the wedge flowmeter;

3, the separate calibration wedge flowmeter have higher measurement accuracy (zui high up to 0.5%), without the accuracy of the calibration of the wedge flowmeter can be around 3%;

4, simple structure, easy installation, use and maintenance;

5, can measure the corrosive medium, due to the differential pressure measurement is the use of diaphragm type double flange differential pressure transmitter, corrosive media can't into the guide tube and the differential pressure transmitter, so as long as with corrosion resistant material processing wedge throttling, can make the gauges for measuring corrosive medium.

Six, the technical parameters:

A degree, the flow measurement range: > 1;

2, measuring diameter: age from 25 to 1000 mm (over range can be special order);

3, the measuring accuracy: 0.5, 1.6;

4, Renault coefficient using range: 300 ~ 1 x108;

5, measuring liquid viscosity limit: 500 mpa. S.

6, scope of work pressure: 6.2 MPa or less;

7, installation and connection mode: flange connection;Welding connection;

8, flowmeter work environment temperature: - 20 - to + 70 ℃;

9, work environment relative humidity: 15 ~ 85%;

10, power supply voltage: 24 v DC;

11, communication methods: RS485.

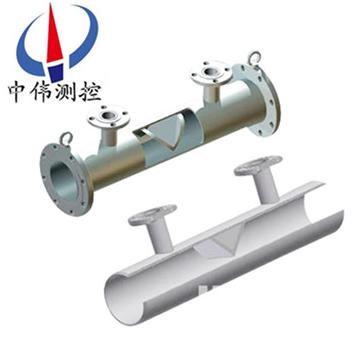

Seven, the classification of the wedge flow sensor and the structure:

According to different product scope of supply, and the output signal, wedge flowmeter can be divided into three categories:

1, wedge sensor;

Provide only the differential signal form part of the wedge device (part), differential pressure transmitter and flow display section is not available, the output signal for the differential pressure.Other configuration shall be conducted by the users themselves.

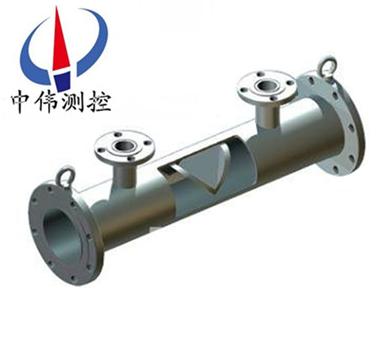

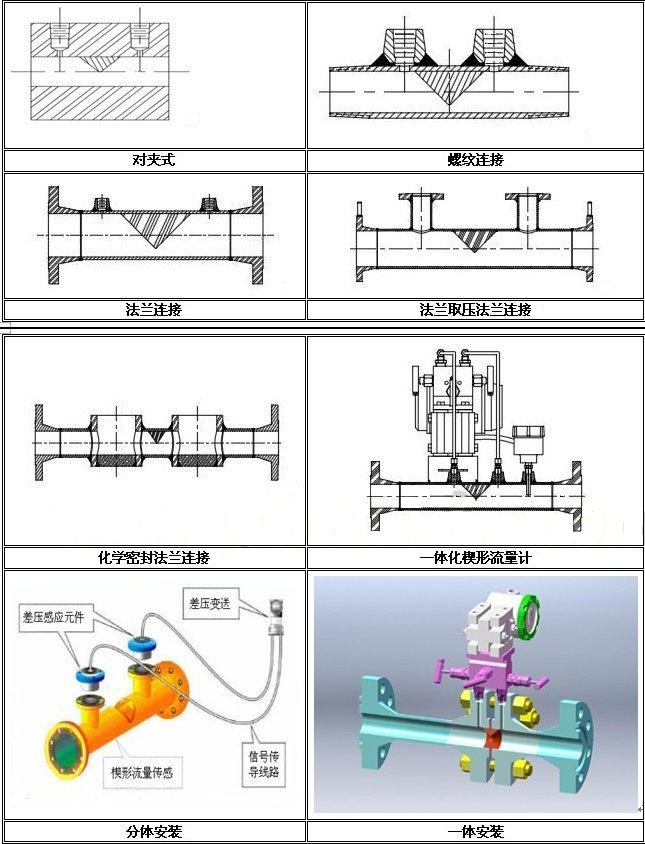

2, wedge flow transmitter;

By the wedge orifice plate flow sensor and differential pressure transmitter.Have a split type installation and one-piece installation structure.

A wedge, orifice flow meter by independent wedge orifice plate flow sensor and differential pressure transmitter.Wedge orifice plate flow sensor and differential pressure transmitter of pressure pipe connection between performed by users themselves.

B, one-piece installation is product factory has the differential pressure transmitter and wedge orifice connected into an organic whole, users buy one-piece wedge orifice flow meter, don't need to join again when using pressure tube.But must be allocated to the corresponding flow calculator, pressure transmitter and temperature transmitter.

C, cut-off valve and other parts.The connection between the parts combination performed by users themselves.Explosion-proof type and ordinary type two kinds.

3, the structure of:

One-piece installation is composed of intelligent display and wedge orifice device a wedge orifice meter.It comes with a high quality of the differential pressure sensor, pressure sensor, the thermal resistance temperature sensor.Type intelligent display not only in the range of differential pressure sensor range automatically adapt to, and all kinds of compensation coefficient such as: flow coefficient C epsilon, flow beam expansion coefficient are calculated for on-line, expanding truly achieve the scale at the same time guarantee the accuracy of measurement.Using large screen LCD screen display with cumulative flow, transient flow, the instantaneous pressure and transient temperature, without manual switch.4-20 ma two wire system transient flow output.

Eight, notable matters of installation:

1, general wedge flow sensor before and after the attached measuring tube, available in horizontal or vertical installation and use.When the sensor installed on the vertical pipe, fluid should flow from top to bottom.The differential pressure transmitter should be paid attention to when measuring liquid can turn over to exclude bubbles, lest cause instrument drift;

2, sensors, straight pipe upstream and downstream side should configure, pipe inner surface should be smooth, clean, no attachments, just length as table

When mounted horizontally, 3, wedge type differential pressure components should be with the center line of the pipeline into 90 degrees.For vertical installations, because of the influence of take slightly between static pressure must pay attention to zero differential pressure transmitter.

Nine, the structure form:

According to the assembly methods are divided into a shape and separation type, according to the connection methods can be divided into flange connection, welding connection, threaded connection and clamp connection, according to the selecting pressure methods can be divided into ordinary take pressure, flange sealing structure, etc.

See the table below:

Ten, the straight pipe upstream side short see the table below:

Wedge thanH/D | Upstream side small straight pipe length | |||

elbow90o | TForm of a tee | Ball valve | Gate valves (full open) | |

0.2 | 6 | 6 | 10 | 6 |

0.3 | 8 | 8 | 11 | 6 |

0.4 | 12 | 12 | 14 | 8 |

0.5 | 14 | 14 | 16 | 10 |

Eleven, flow range:

1, measuring the liquid flow range:

model | Nominal diameterDN(mm) | Wedge ratio (H/D) | Flow range (m³/h) |

ZW-LGX015 | 15 | 0.2,0.3,0.4,0.5 | 0.11 ~ 2.7 |

ZW-LGX020 | 20 | 0.2,0.3,0.4,0.5 | 0.2 ~ 4.8 |

ZW-LGX025 | 25 | 0.2,0.3,0.4,0.5 | 0.3 ~ 7.4 |

ZW-LGX032 | 32 | 0.2,0.3,0.4,0.5 | 0.5 ~ 12.2 |

ZW-LGX040 | 40 | 0.2,0.3,0.4,0.5 | 0.8 ~ 19 |

ZW-LGX050 | 50 | 0.2,0.3,0.4,0.5 | 1.3 ~ 29.7 |

ZW-LGX065 | 65 | 0.2,0.3,0.4,0.5 | 2.2 ~ 50.1 |

ZW-LGX080 | 80 | 0.2,0.3,0.4,0.5 | 3.3 ~ 76 |

ZW-LGX100 | 100 | 0.3,0.4,0.5 | 8.2 ~ 118.7 |

ZW-LGX125 | 125 | 0.3,0.4,0.5 | 12.8 ~ 185.5 |

ZW-LGX150 | 150 | 0.3,0.4,0.5 | 18.4 ~ 267.1 |

ZW-LGX200 | 200 | 0.3,0.4,0.5 | 32.7 ~ 474.8 |

ZW-LGX250 | 250 | 0.3,0.4,0.5 | 51.2 ~ 741.8 |

ZW-LGX300 | 300 | 0.3,0.4,0.5 | 73.8 ~ 1068.2 |

2, measuring the flow range of gas:

model | Nominal diameterDN(mm) | Wedge ratio (H/D) | Flow range (m³/h) |

ZW-LGX015 | 15 | 0.2,0.3,0.4,0.5 | 1.2 ~ 19.1 |

ZW-LGX020 | 20 | 0.2,0.3,0.4,0.5 | 2.3 ~ 33.9 |

ZW-LGX025 | 25 | 0.2,0.3,0.4,0.5 | 3.5 ~ 53 |

ZW-LGX032 | 32 | 0.2,0.3,0.4,0.5 | 5.8 ~ 86.8 |

ZW-LGX040 | 40 | 0.2,0.3,0.4,0.5 | 9.0 ~ 135.7 |

ZW-LGX050 | 50 | 0.2,0.3,0.4,0.5 | 14.1 ~ 212 |

ZW-LGX065 | 65 | 0.2,0.3,0.4,0.5 | 23.9 ~ 358.2 |

ZW-LGX080 | 80 | 0.2,0.3,0.4,0.5 | 36.2 ~ 542.6 |

ZW-LGX100 | 100 | 0.3,0.4,0.5 | 56.5 ~ 847.8 |

ZW-LGX125 | 125 | 0.3,0.4,0.5 | 88.3 ~ 1324.5 |

ZW-LGX150 | 150 | 0.3,0.4,0.5 | 127.2 ~ 1907.6 |

ZW-LGX200 | 200 | 0.3,0.4,0.5 | 226.1 ~ 3391.2 |

ZW-LGX250 | 250 | 0.3,0.4,0.5 | 353.3 ~ 5298.8 |

ZW-LGX300 | 300 | 0.3,0.4,0.5 | 508.7 ~ 7630.2 |

Twelve, selection of coding:

spectrum | Code name | Shell material | Nominal pressure | Working temperature | Connection and take pressure | instructions |

ZW-LGX | Wedge flowmeter (wei) | |||||

015 | DN15 | |||||

020 | DN20 | |||||

025 | DN25 | |||||

… | ||||||

300 | DN300 | |||||

I | Carbon steel | |||||

II | Stainless steel | |||||

III | Special customized | |||||

0.25 | 0.25MPa | |||||

0.60 | 0.6MPa | |||||

… | ||||||

5 | 5MPa | |||||

A | - 20 ~ 100℃ | |||||

B | 100 ~ 250℃ | |||||

C | 250 ~ 400℃ | |||||

A | Thread with the wafer | |||||

B | Thread take pressure type | |||||

C | Take pressure welded screw thread | |||||

D | Take pressure flange thread | |||||

E | Flange pressure flange | |||||

F | Integration installation (temperature, pressure compensation) | |||||

G | The integration of general type installation |

13 order, design notes:

When you place an order, please provide the following conditions in order to help the correct choice of the specifications of the flowmeter and coefficient.

1, pipe size: diameter x wall thickness (mm);

2, measuring medium name: medium density (kg/m3);

3, set the flow range: meter range of upper limit and lower limit (kg/h or m3 / h);

5, work pressure (Mpa);

6, work temperature: (° C);

7, such as wei in my company, please provide together: intelligent flow totalizer.especially pressure range, or pressure transmitter type, range;Temperature range, or models, range temperature transmitter.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.