Nozzle flowmeter

Products overview:

ZW series of LGPNozzle flowmeterHas a long history background, all kinds of test data is complete.Simple structure, no moving parts, stable and reliable long-term use, rich experience in design and manufacture and application.Doesn't need a high degree of standardization, solid flow calibration.Standard orifice has reliable experimental data and improve the international and national standards.In foreign countries and has its inherent in the huge domestic market, users are familiar with, data;Follow the international standard calculation and processing, use agile and convenient;The most widely used in domestic flow measurement is still the differential pressure type flowmeter.

Nozzle with high temperature and high pressure resistance, impact resistance, long service life, large measuring range and accuracy of measurement, suitable for high power plant high temperature and high pressure steam heat-supply pipeline flow of fluid flow measurement.Standard nozzle design and manufacture according to GB/T2624-93, according to JJG640-94 verification, without real flow calibration.

Second, the working principle:

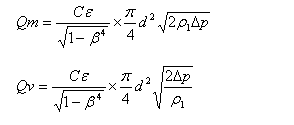

ZW series of LGPThe principle is to use the throttle nozzle flowmeter flow sensor.It adopt special on the basis of the nozzle pressure (pressure) throat way, make the flow sensor not only has the advantages of traditional long neck nozzle, at the same time also have outflow coefficient of stability, repeatability of higher unique advantages.Is a kind of high precision flow sensor.Flow calculation formula:

Type: - mass flow respectively (㎏ / s) and the volume flow (m3 / s);

- flow coefficient;

- expansiveness coefficient;

-- the throttle hole diameter, m;

- diameter ratio,

- pipe diameter, m;

- the flow volume density, ㎏ / m;

-- differential pressure, Pa;

By measuring the pressure difference to measure the size of the fluid flow.This kind of measurement method based on the energy conservation law and the law of flow continuity as a benchmark.Fluid filled with pipes, when they flow through the pipe of the throttle device, a beam will local contraction at the throttling of the throttle device, so that the flow velocity increases, the static pressure is low, so the throttling parts before and after the pressure drop is produced, the pressure difference, the greater the flow of medium flow, on the throttling the greater the pressure difference before and after.

Applications:

ZW series of LGPNozzle flow meter is to measure flow differential pressure generator, cooperate with all sorts of differential pressure gauge or differential pressure transmitter to measure all kinds of fluid flow in pipes.Standard nozzle throttling device with differential pressure transmitter, can measure the rate of flow of liquid, steam, gas, widely used in petroleum, chemical, metallurgical, power, light industry and other departments.Measured medium is as follows:

1, liquid: hot and cold water, chemical liquid, light body oil.

2, gas, blast furnace gas, coke oven gas, all kinds of single-component multicomponent gas.

3, superheated steam and saturated steam.

4, compressed air.

5, natural gas, the torch gas, liquefied petroleum gas.

Four, the main features:

1, the throttle device structure easy to copy, simple, firm, stable and reliable performance, long service life, low price.

2, nozzle adopt international standards and processing

3, nozzle application range is wide, all single-phase flow are measured, partially miscible flow can also be applied.

4, standard throttle device without real flow calibration, putting-in-service proactively.

5, using imported monocrystalline silicon intelligent differential pressure sensor

6, high precision, perfect the self-diagnosis function

7, the intelligent standard nozzle intelligent orifice flowmeter range can be adjusted from the programming.

8, intelligent standard nozzle can be displayed at the same time the cumulative flow and transient flow, pressure, temperature.

9, have the functions of online, dynamic full compensation, intelligent orifice plate flowmeter has since diagnosis, set range.

Five, the technical parameters:

1, the nominal diameter: 20 mm or less DN 630 mm or less;

2, nominal pressure: PN acuities were 32 mpa;

3, working temperature: - 50 ℃ or less t 550 ℃ or less;

4, Reynolds number range: 0.30 beta 0.44 or less, or less 70000 ReD 107 or less or less;

0.44 beta 0.8 or less, or less 20000 ReD 107 or less or less;

5, throat diameter ratio: 0.30 beta 0.80 or less or less;

6, precision: 0.5, 1.0, 1.5, 2.0;

7, the reference standard: GB/T2624-2006, JJG640-94;

8, connection mode: flange, welding.

Six, orifice plate and nozzle flowmeter are two different types of differential pressure type flowmeter:

1, the nozzle flow meter

Advantages: long neck nozzle has a long history, there are a large number of all kinds of test data, the nozzle flow meter has simple structure and firm, no moving parts, stable and reliable long-term use, rich experience in design and manufacture and application, high degree of standardization, can need not to flow calibration.Standard nozzle has reliable experimental data and improve the international and national standards.Authentic measurement data, can be used as a trade settlement measurement table.

Disadvantages: manufacturing complex, the unit price is higher.

2, the orifice plate

Orifice meter advantages: high cost performance.Standard orifice plate has a long history, the international and national standards and verification regulations and a large number of experimental data, without real flow calibration.Authentic measurement data, can be used as a trade settlement measurement table.

Faults: orifice acute Angle edge wear, dirt and other factors will affect measuring accuracy.Verification cycle short 6 to 12 months.

Seven, the structure form:

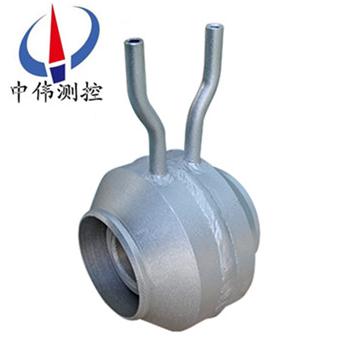

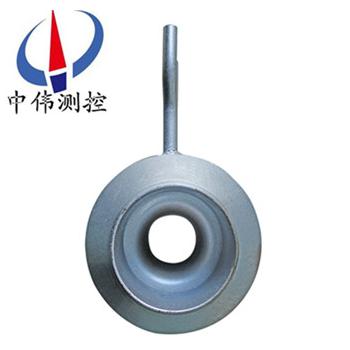

Nozzle flowmeter by part A, perpendicular to the axis of the entrance surface of circular arc form surface B and C part and shrinkage of the entrance of the cylindrical throat E and protection of the edge of to prevent damage to the groove of F, its take pressure way upstream pressure mouth Angle of using access, downstream take pressure can be set up by the pressure of Angle joint, also can be set up in the far downstream.The total length of the nozzle

A, when 0.30 beta 2/3 or less or less, the nozzle length = 0.6041 d.

B, when two-thirds beta 0.80 or less or less, the nozzle length = {0.4041 + (0.75 / beta 0.25 beta 2-0.5225) 0.5} d;

C, ISA 1932 nozzle upstream face by perpendicular to the axis plane and profile for the two arcs of a circular, cylindrical throat and groove for the identified contraction of the nozzle.ISA1932 nozzle way of selecting pressure Angle only pressure a pick up.

Eight, notable matters of installation:

1, can be horizontal, vertical or inclined installation, should guarantee the tube filled with liquid.

2, the throttle device before and after the straight pipe should be straight, bend without visible to the naked eye, at the same time, should be "round", inner surface should be clean, without potholes and sediment;

3 and the request of straight section length and throttling device installation should be in conformity with the relevant provisions of the GB/T26224-93.

4, lead pressure pipeline installation should comply with the standards stipulated by the regulations.

Nine, scope of application and characteristics:

Throttling a name | Apply pipe (DN mm) | Apply to diameter ratioB(d/D) | Application characteristics | Uncertainty of outflow coefficientEc% | Design criteria | |

Angle of access standard orifice plate | Ring chamber type | 50-500 50-500 | 0.2-0.75 0.2-0.75 | Apply to clean mediumGDUnder the condition of structure is suitable for high temperature and high pressure flow rate measurement | 0.6-0.75% | ISO5167 GB/T2624-93 |

The clamping ring type | 50-500 | 0.2-0.75 | Easy to remove dirt, and can be used to clean fluid flow measurement | |||

Oblique hole type | 450-1000(3000) | 0.2-0.75 | ||||

Flange pressure standard orifice plate | 50-1000 | 0.2-0.75 | Easy to remove dirt, and are suitable for all kinds of media | 0.6-0.75% | ISO5167 GB/T2624-93 | |

Span with standard orifice plate | 50-1000 | 0.2-0.75 | ||||

Angle access standard pressure nozzle (ISA1932Nozzle) | 50-500 | 0.3-0.8 | Small pressure loss, long life, especially suitable for steam flow measurement | 0.8-1.2% | ISO5167 GB/T2624-93 | |

The length to diameter nozzle | 50-630 | 0.2-0.8 | Small pressure loss of long service life,LGPType of length to diameter nozzle components for high parameters of water and steam flow measurement | 2.0% | ISO5167 GB/T2624-93 | |

Classic venturi tube | Mechanical processing type | 100-800 | 0.2-0.8 | The pressure loss is small, straight pipe required less than orifice, nozzle | 1.0% | ISO5167 GB/T2624-93 |

Soldering iron plate type | 200-1200(2000) | 0.4-0.7 | 1.5% | |||

Venturi nozzle | 65-500 | 0.316-0.77 | Same as above | 1.2-1.75% | ISO5167 GB/T2624-93 | |

A quarterRound hole plate | 25-150 | 0.245-0.6 | Suitable for low Reynolds number | 2.0-2.5% | DIN BS | |

Conical inlet orifice | 25-250 | 0.1-0.316 | Same as above | 2.0% | BS | |

Segmental orifice | 50-1500 | 0.32-0.8 | Apply to the smudges, there are air bubbles or containing solid particles flow measurement. | 1.5% | DIN | |

The eccentric orifice plate | 100-1000 | 0.46-0.84 | 1-2% | ASME | ||

Small hole plate | 12.5-40 | 0.2-0.75 | Applicable to small pipe flow measurement | 0.75% | ASME | |

Lens type orifice | 12.5-150 | 0.2-0.75 | Suitable for high pressure temperature small pipe flow measurement | 0.6-0.75% | ISO5167ASME | |

Ten, classification model parameter table:

The name of the | model | Take pressure way | Nominal pipe diameter (mm) | Nominal pressure (MPa) | Execution standard (structure) |

The standard orifice plate | LGB | Pressure Angle joint (annulus) | 50~400 | Less than10 | GB2624 K07 |

LGB-Z | Pressure Angle joint (drilling) | 400~2000 | Less than1.6 | ||

LGB | Ring chamber (8 slot) | 50~400 | Less than32 | The flow measurement manual | |

LGB | Ring room (no flange welded) | 50~275 | Less than28.22 | The flow measurement manual | |

LGB-F | The flange to take pressure | 50~800 | Less than2.5 | GB2624 K06 | |

LGB-F | The flange to take pressure | 50~400 | 4.0~40 | GB2624 K06 | |

LGB-J | Diameter of pressure | 50~760 | Less than10 | GB2624 | |

Standard nozzle | LGP | Pressure Angle joint (annulus) | 50~400 | Less than10 | GB2624 The flow measurement manual |

LGP-Z | Pressure Angle joint (drilling) | 400~500 | Less than1.6 | ||

LGP | Ring chamber (8 slot) | 50~300 | Less than32 | The flow measurement manual | |

LGP | Ring room (high pressure lens pad) | 15~150 | Less than32 | ||

LGP | Ring room (no flange welded) | 175~350 | Less than17.36 | DG 0702~0710 | |

The length to diameter nozzle | LGC-J | Diameter of pressure | 50~630 | Less than16 | GB2624 |

A quarterRound hole plate | LGH | Take pressure Angle joint | 50~260 | Less than10 | GB2624 The flow measurement manual |

LGH-F | The flange to take pressure | 50~200 | Less than6.4 | ||

Venturi nozzle | LGL | Take pressure Angle joint | 65~500 | Less than2.5 | |

Venturi tube | LGW | Take special pressure | 50~1200 | Less than2.5 | |

Double venturi tube | LGW-S | Take special pressure | Less than1000 | Less than0.6 | |

Small diameter orifice | LGX | Take pressure Angle joint | 12~40 | Less than6.4 | K07(LanHua) |

LGX-F | The flange to take pressure | 12~40 | Less than6.4 | The enterprise standard | |

High pressure lens gasket | LGT | Take pressure Angle joint | 50~150 | Less than32 | The flow measurement manual |

Segmental orifice | LGQ | Pressure Angle joint (annulus) | 100~400 | Less than1.6 | |

LGQ-Z | Pressure Angle joint (drilling) | 400~1000 | Less than1.6 | ||

LGQ-F | The flange to take pressure | 100~350 | Less than6.4 | ||

Double orifice | LGS | Take pressure Angle joint | 100~400 | Less than6.4 | |

The eccentric orifice plate | LGN | Take pressure Angle joint | 100~1000 | Less than6.4 | |

Current limit orifice | LG-XL | 10~300 | Less than6.4 | The enterprise standard | |

Conical inlet orifice | LGR | Take pressure Angle joint | 25~1000 | Less than10 | GB2624 |

The wing wind device | LJY | Take special pressure | Less than1000 | Less than0.6 | The enterprise standard |

Eleven, selection of coding:

model | said Ming | ||||||||

ZW-LG | The throttle device (wei measurement and control) | ||||||||

Code name | According to the structure characteristics of the two basic categories | ||||||||

B | The standard orifice plate | ||||||||

P | Standard nozzle | ||||||||

Code name | Nominal pressure (105Pa) | ||||||||

2.5 | 2.5 | ||||||||

10 | 10 | ||||||||

16 | 16 | ||||||||

25 | 25 | ||||||||

64 | 64 | ||||||||

100 | 100 | ||||||||

200 | 200 | ||||||||

Code name | CAL(mm) | ||||||||

15~1200 | 15~1200mm | ||||||||

Code name | According to its structure form of segmentation | ||||||||

H | The standard orifice plate(Ring chamber) | ||||||||

Y | The standard orifice plate(The flange) | ||||||||

K | The standard orifice plate(drilling) | ||||||||

I | ISA 1932The nozzle | ||||||||

L | The length to diameter nozzle | ||||||||

W | Venturi nozzle | ||||||||

G | Classic venturi tube | ||||||||

S | Double orifice | ||||||||

Q | Segmental orifice | ||||||||

Z | Conical inlet orifice | ||||||||

R | A quarterRound hole plate | ||||||||

P | The eccentric orifice plate | ||||||||

N | As a whole(Hidden within)Orifice plate | ||||||||

X | Wedge orifice | ||||||||

T | Out of place in the above special throttling device | ||||||||

Code name | medium | ||||||||

1 | liquid | ||||||||

2 | gas | ||||||||

3 | steam | ||||||||

4 | High temperature liquid | ||||||||

Code name | Compensation in the form of | ||||||||

N | Without pressure and temperature compensation | ||||||||

P | With pressure compensation output | ||||||||

T | With temperature compensation output | ||||||||

Q | With compensation output pressure and temperature | ||||||||

Code name | Differential pressure transmitter range scope | ||||||||

0 | Micro differential pressure range | ||||||||

1 | Low differential pressure range | ||||||||

2 | The differential pressure range | ||||||||

3 | Elevation difference pressure range | ||||||||

Code name | Whether or not to bring a live show | ||||||||

W | The throttle device sensors | ||||||||

X | Intelligent throttling device | ||||||||

13 order, design notes:

When you place an order, please provide the following conditions in order to help the correct choice of the specifications of the flowmeter and coefficient.

1, pipe size: diameter x wall thickness (mm);

2, measuring medium name: medium density (kg/m3);

3, set the flow range: meter range of upper limit and lower limit (kg/h or m3 / h);

5, work pressure (Mpa);

6, work temperature: (° C);

7, such as wei in my company, please provide together: intelligent flow totalizer.especially pressure range, or pressure transmitter type, range;Temperature range, or models, range temperature transmitter.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.