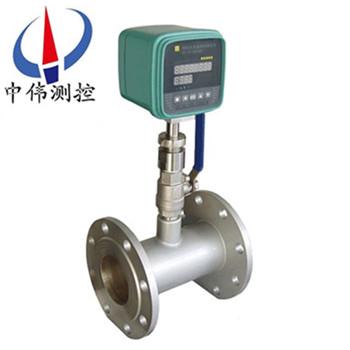

Hot gas mass flowmeter

I. product overview

Zw-rsl series hot gas mass flowmeter is an instrument for measuring fluid flow based on the principle of heat conduction. The product flowmeter is a real direct mass flowmeter, the user does not have to compensate for the pressure and temperature. The instrument has no moving parts, small pressure loss, wide range ratio, high accuracy, high reliability, simple installation, easy operation.

There are two types of gas mass flow meters: plug-in type and tube type. The plug-in sensor is 1/2" in diameter and 36" long (914mm) probe (longer sensor can also be manufactured). Measuring tube with measuring tube sensor with 1/4 to 6" (6.25mm to 152mm), with built-in flow regulator so that there is no need to have long straight pipe section upstream and downstream, pipe connection can be flange, NPT thread or welding. Material: 316 stainless steel, hastelloy C alloy or other materials.

Ii. Working principle

Zw-rsl series hot gas mass flowmeter is based on heat conduction technology to measure gas mass flow. The measuring probe of the flowmeter has two platinum resistance sensing elements. They are placed in a fluid, one of which is heated by power P to a temperature of T 1, the other is not heated and is used to monitor the temperature of the medium, let's call it T2. Thus temperature difference between the two sensing elements can be set (T= t1-t 2). When the flow is zero, delta Tz large, with the increase of mass flow Q, the heat of the sensing element T1 was taken away, T1 decreased, delta T decreased. Therefore, the above heating power P, temperature difference T and mass flow Q will have a certain relationship.

Under the available type said: P/T = K1 + Δ K2F (Q) K3 (1) the type of K1, K2, K3 is related with the physical properties of gas constant.

It can be seen from the above equation that mass flow Q can be obtained by measuring the heating power P and temperature difference T. In order to simplify the problem, the actual work is to heat power P or temperature difference (T) one remains the same. The former is called constant power type, and the latter is called constant temperature difference type. Choose one of these to work according to different requirements.

Iii. Application:

1. Public engineering -- monitoring of electricity, gas and water treatment;

Pipe gas; General system; Biogas; The gas; Natural gas; Liquefied petroleum gas. Preheat the boiler air.

2. Oil and gas industry;

Energy exchange; Well filling gas recovery; Gas metering; Gas quality analysis; Leakage gas test; Natural gas measurement; Monitoring of flare gas.

3. Power industry;

Gas measurement during gas distribution in fuel system; Measurement of various gases in boilers and auxiliary systems; Gas measurement in gas furnace; Hydrogen measurement; Measurement of primary and secondary air of blast furnace in power plant.

4. Chemical industry;

Flue gas cycle monitoring; Measurement of gas flow in the sampling system; Gas flow measurement of induced draft fan; Ammonia gas measurement in fertilizer plant; Battery plant various gas flow measurements.

5. Metallurgical industry;

Measurement of aeration in steel works; Measurement of blast furnace gas in iron works; Measurement of coke oven gas in coking plant; Measurement and control of heating furnace gas (blast furnace gas, coking gas, natural gas, etc.) in rolling mills; Control of hydrogen, oxygen, nitrogen and other gases in heat treatment quenching furnace.

6. Pulp and paper industry;

Measurement of gases in wastewater treatment systems; Flue flow monitoring; Boiler recovery of secondary/tertiary air; Boiler gas and air supply measurement.

7. Food and pharmaceutical industry;

Addition of fresh air during processing operation; Co2 treatment in breweries; The flow of hot air in the bottle sterilizer; Measurement of gas flow during thermal oxidation; Ventilation system; Boiler intake, exhaust, process control.

8. Environmental protection;

Gas measurement in the process of biogas utilization; Gas measurement of aeration tank in sewage treatment process; Monitor the displacement of SO2 and NOX in chimney flue.

9. Other industries;

Factory compressed air measurement; Fuel control by powder/gas ratio in pulverized coal combustion process; Thermal discharge control of vertical mill in cement industry.

Iv. Main features:

1. Adopt platinum RTD sensor with extremely high stability;

2, using proprietary technology "balanced structure package ", medium temperature self-compensation;

3, proprietary algorithm, can achieve high linearity, high repeatability, high precision;

4. The range ratio is 1000:1, which can be expanded according to user requirements;

5, can achieve large diameter small flow measurement, zui small flow can be measured as low as zero, the resolution of 0.001m/s;

6, no moving parts, vibration can be ignored;

7. The requirements for the straight pipe section are not high 1-2d;

8. Independent of the temperature and pressure of the medium;

9, proprietary algorithms by high temperature, medium temperature can be up to + 510 ℃;

10. High humidity algorithm is adopted to realize high-precision measurement;

11. Key 12 dynamic correction points into the flow signal, and built-in 10 correction points;

12. Online dynamic correction current/voltage output;

13. Insensitive to small particles such as dust;

14, online non-stop loading and unloading, easy maintenance.

V. technical parameters:

1, measuring range: (0.05 ~ 80 Nm)/s (standard state is 20 ℃, and 101.33 KPa);

2. Measuring medium: clean gas except acetylene;

3, temperature range: ambient temperature: - 40 ℃ ~ + 60 ℃.

4, medium temperature: - 10 ℃ ~ + 200 ℃;

5. Accuracy: 1%; 0.5% full range;

6. Repeatability: 0.5% full range;

7, lose out: the instantaneous flow rate of 4-20 ma DC zui big load 600 Ω, RS232 and RS485.

8. Response speed: less than 1S;

9. Power supply voltage: 24VDC 10%;

10. Mechanical connection: 3/4 NPT stainless steel fasteners;

11. Length of probe rod: 800mm (this length is standard length, please specify);

12. Probe rod diameter: 18mm;

13. Straight pipe length: no strict requirements;

14. Pressure loss: negligible;

15. Working pressure: 1.6mpa;

16. Field display :(LED) the upper row is 4 characters per line for instantaneous flow, and the lower row is 8 characters per line for cumulative flow. The flow and cumulative flow can be displayed in British or metric units.

17. Data protection: the accumulative amount is saved in EEROM (it can be saved for 100 years after power failure);

18. Sensor and pipeline surface material :316L (optional hastelloy C);

19. Protection level: IP65;

20. Transmission unit: explosion-proof package is selected.

Vi. Classification:

The meter is divided into plug-in type and pipeline type, and can be further subdivided according to connection mode and diameter, as follows:

1. Zw-rslc-1 plug-in base type;

2. Zw-rslc-2 plug-in flange connection type [flue gas flow rate (velocity) meter];

3. Zw-rslc-3 plug-in jacket (3/4 "NPT) connection type;

4. Zw-rslc-4 plug-in jacket + ball valve connection type;

5. Zw-rslc-5 insert seal + ball valve connection type;

6. Zw-rslg-1 pipe type (DN40, DN50, DN80, DN100);

7. Zw-rslg-2 pipe type (DN20, DN25);

8. Zw-rslg-3 pipe type (DN10, DN15, DN20A, DN25A);

Vii. Determination of the upper and lower limits of the range:

1. Determination of the lower limit: because the gas mass flowmeter is sensitive to low flow rate and zui can measure a low flow rate of 0.05m/s, the lower limit is not considered in the selection;

2. Determination of upper limit: it is mainly determined by the design value of the process flow. The upper limit of the general instrument is about 20% higher than the design upper limit to improve the fault tolerance rate;

3. Range of mixed gas: for mixed gas, the user shall give the standard density and molar ratio (the percentage of each component in the total amount), and then the range shall be determined by the manufacturer. Generally using air or nitrogen calibration, and then through the instrument conversion coefficient correction;

Statement:

The upper limit of range selection is limited by equipment conditions. Please confirm the technical details with the manufacturer before purchasing with high limit.

Installation mode selection:

1. Suggestions: when the pipe diameter is less than or equal to 100, select pipe installation;

Select insert installation for tube diameter > 100.

2, if the field pipe has been installed, there is no installation flange, can only choose to insert the installation mode, can be ordered with the manufacturer.