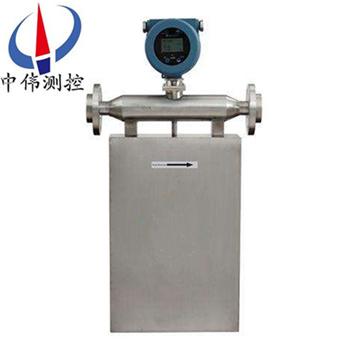

Intelligent mass flowmeter

ZW - CMF seriesIntelligent mass flowmeterInside the sensor has two parallel vibration u-shaped tube, coil, equipped with central China at both ends is equipped with coil vibration picking, mass flowmeter directly measured through the medium of mass flow meter, can also be measured medium density and indirect measurement of the temperature of the medium.Measured by thermal type mass flowmeter is.Is an advanced high accuracy mass flow meter.Due to its superior performance, make it high measurement accuracy, low requirement to the fluid state, the pressure loss is small.A variety of specifications of the instrument can be directly obtained by measuring the quality of the liquid or slurry flow, volume flow, density, temperature, without artificial calculation or estimate.

Second, the structure principle:

1, the principle of:

ZW - CMF series intelligent structure of the mass flowmeter is double pipe structure, its measurement principle is applied to double bend up detection by measuring the mass flow in the pipeline.In the process of industrial production, sometimes need to measure the mass flow of the fluid, such as chemical reaction of material balance, heat balance, ingredients, etc., all need to measure the mass flow of the fluid.Mass flow rate is to point to in unit time, through the closed pipeline section in the quality of the fluid.Used to measure the mass flow meter are collectively referred to as mass flowmeter.

2, the structure:

By the sensor, transmitter, cumulative Numbers indicate three parts, etc.Sensor by sensing tube, electromagnetic drive, and electromagnetic detector of three parts.Electromagnetic drive the sensor with its natural frequency of vibration, and the flow of imported make u sensor produces a distorted, under the action of a phase difference on both side of it, the phase difference is proportional to the mass flow rate.Electromagnetic monitor transform the phase difference for a corresponding level signal into transmitter, after filtering, integral, amplification and dealing with power.Into is proportional to the mass of 4-20 ma analog signal and a range of two forms of output frequency signal.

Applications:

ZW - CMF series intelligent mass flowmeter is mainly used to measure the mass flow, volume and density in the medium, at the same time, it also can measure flow rate and total volume, medium temperature, moisture content, the alcohol content of alcohol, are uniformly mixed in the two kinds of liquid concentration, technological process of raw material ratio, etc.It is mainly suitable for the following industries:

1, the oil industry, such as crude oil output measurement, moisture content, the single well production and transportation of crude oil metering;

2, the chemical industry;

3, the food industry;

4, papermaking industry, such as pulp measurement;

5, textile printing and dyeing industry.

6, energy transmission measurement, such as liquefied gas metering;

7, the environmental protection industry, such as sewage treatment;Desulfurization process of slurry density.

Four, the main features:

1, the direct measurement of mass flow rate of the pipe inner fluid:

High measurement accuracy and repeatability, but in a larger range within the scope of direct measurement of fluid mass flow;The accuracy of the measurement of the flowmeter are high mass flow measurement accuracy of 0.2;

2, work stable and reliable:

Flow measurements of the interior of the tube without obstacles and moving parts, thus high reliability, long service life;

3, to adapt to the fluid surface width:

In addition to the general's uniform fluid viscosity, it can also be measured high viscosity fluid (honey, slurry, etc.);Fluid parameters of a single solution can be measured not only, still can measure multiphase flow;Whatever medium is laminar or turbulent, does not affect the measurement accuracy;

4, a wide range of applications:

Applicable to petrochemical, chemical, metallurgical, pharmaceutical, paper making, food, energy and environmental protection industries, in the detection and control of process and custody transfer metering and other occasions, gained widespread application;

5, a variety of real-time online measurement and control work:

In addition to the mass flow rate, fluid density and temperature can be directly measured.Intelligent flow transmitter, can provide a variety of parameter display and control functions, is a collection of multi-function as one of the flow measurement and control instrument;

6, good scalability:

Company can according to user needs, specialized design and manufacture of special specifications and special function of the mass flowmeter;But also for remote monitoring operation, etc.

Five, the technical parameters:

1, the measurement accuracy: + / 0.2% + (zero stability/instantaneous mass flow (100%);

2, measurement repeatability, plus or minus (1/2) x [+ 0.2% (zero stability/instantaneous mass flow (100%);

3, density measurement range: 0.2 g/cm3 ~ 3.5 g/cm3;

4, density measurement accuracy: + / - 0.002 g/cm3;

5, temperature measuring range: 60 ℃ ~ + 200 ℃;

6, temperature measurement accuracy: + / - 1 ℃;

7, current output: 4 ma ~ 20 ma;

8, frequency output: 0 hz ~ 10 KHZ.

9, batch control relay contact capacity: 24 v / 0.1 A;

10, batch control relay contact forms: normally open (user ordering can be changed to normally closed);

11, fluid temperature: - 40 ℃ ~ + 200 ℃;

: 12, working environment temperature 0 ℃ ~ + 40 ℃.

13, work environment humidity: 90% RH or less, the condensation;

14, atmospheric pressure: 86 kpa to 106 kpa.

15, transmitter power supply requirements: this type of power supply voltage AC (220 + / - 10%) V or Hz (50 + / - 5%), composite power supply voltage (24-10%) V;

The machine power: < 15 w.

Six, the main functions:

1, the measurement function

Directly measuring the instantaneous mass flow rate of liquid medium, accumulative total quality, volume flow, total volume, temperature, density, concentration of two-component liquid, etc.Can display, export, storage and remote transmission;Modify the flowmeter parameters.

2, current output

A current signal output function, is 4 ma ~ 20 ma output current, can meet the demand of industrial instrumentation control.

3, frequency output

A frequency signal output function, frequency output is 0 KHZ ~ 10 KHZ, can meet the demand of industrial instrumentation control.

4, batch control

Batch control relay contact capacity: 24 v / 0.1 A, contact form for normally open (user ordering can be changed to normally closed), the function can meet the traffic volume of industrial equipment control.

5, communication function

The products include data communication function, can be through the RS - 485 communication, complete with the computer data communication, computer network control can be realized.

6, safety explosion-proof

The company has obtained double explosion-proof certificate for the mass flowmeter.

Seven, installation requirements:

Mass flowmeter installation environment for mass flowmeter is a high precision measuring instrument, in order to ensure measurement accuracy, to ensure the installation of environmental requirements:

1, sensors (a table) and the transmitter (secondary) shall not be installed in an area where have strong magnetic interference, otherwise it will influence the signal of circuit, which affect measurement accuracy;

2, sensors (a) installation of the pipeline cannot have other vibration interference;

3, the need to be installed outdoors, to pay attention to the environmental temperature zui high and low zui, should consider wind block rain, prevent the wind rain, in order to improve the working life of the meter;

4, the transmitter (secondary) Ann type flowmeter should be placed on safety or suitable control room;

5, the Ann type flowmeter sensor (a table) and the transmitter (secondary) consists of ten core shielded cable connection between;

Eight, installation method:

1, the horizontal line

Main body downwards, measuring liquid, exports must be above 0.8 m high;

2, the main body in inversion

Since the emptying, measuring slurry, containing solid export must be higher than the flowmeter zui high 0.8 meters;

3, flag type installation (measurement)

Since the emptying, measuring liquid or slurry, must be from the bottom to upper.

Nine, fault handling:

Liquid mass flowmeter is generally not a failure, it doesn't matter fails, careful analysis the reason can the problem be solved, such as the working condition of ever changing, ever, isn't it just returned check to use and so on, the following simple introduce several kinds of faults and handling:

1, a hardware failure:

If a big error, integrator show bright, or appreciation, the phenomenon such as display a blank, the reason:

A.Installation is not standard, can be directly lead to flowmeter zero drift, such as the mass flowmeter are installed in the pump outlet, the sensor support strength is not enough, connecting flange welding undeserved produce stress signals, cable affected by electromagnetic interference.

B.Connection problem

If a display is not bright, should check the integrator power cords, if the fuse was burned, shall confirm the input voltage with the standard nominal value, ac/dc form are consistent.And if appear integrator with the increase of flow rate, should check the integrator connection, if the integrator is equipped with is/reverse procedure, check the wiring of the flow meter, for flow meter wiring is not correct, will make the integrator in reverse flow without increasing.

C.Process medium change

If measured medium gas entrapment, gasification or two phase flow phenomena, such as alarm display will appear in the transmitter, serious when, sensor to stop working.

D.Transmitter failure.

E.The sensor failure.

F.Pipe purging.

2, software problem:

For just finished checking the flow meter installed before use must pay attention to under the current conditions of zero calibration, must ensure that the meter is filled with medium after close the cut-off valve on both ends to zero calibration, there are many kinds of, specific methods, hand operator panel operations and use ProLink Ⅱ software.

A.The zero calibration is wrong;

B.Parameter Settings;

C.The power of the pulse wave;

D.The I/O configuration is wrong (it is important to note that range);

E.Wrong operation.

Ten, install and use notice:

1, the flow sensor installation general requirements

By dry sounding pipe shape and structure design of the differences, the weight of the same caliber similar flow range different types sensors and size difference is very big, 80 mm light person only 45 tons, for example, the person that weigh up to 150-200 kg.Installation requirements also differ in thousands ways, so must be installed according to the regulations of the manufacturer's method and the flight from prohibited items, such as some models flow sensor can be directly connected to the line, but some models to set the racks or foundation.To isolate pipeline vibration meter, sometimes want to interface with flexible pipe connection between sensor and pipeline, and between flexible pipe and sensors to a supported a fixed rigid straight tube, respectively.Before the choose and buy should be to buy CMF manufacturer for installation instructions reference comparison and choice.

Installing a design as far as possible to make it have a long use life, to get rid of premature wear and gases, solids and inclusions measurement error caused by fluid and the conditions of pipeline in sensors upstream filter or protective devices such as gas separator.If hope to be able to online calibration instrument at the scene, drainage should be considered joint and valve, and the corresponding space.

2, flow sensor installation position and location

Residual solids flow sensor measuring tube, scaling, and retention of gas will affect the measurement accuracy.Usually installed in the vertical pipe flow from bottom to top is relatively ideal;But for the straight shape on the sounding pipe in a vertical or horizontal tube, depending on the pipeline vibration conditions and application conditions.Installation location must make the measuring tube filled with liquid, such as horizontal pipe runs after the fluid flows through the direct release container without back pressure, measuring tube can not be full of, can make the output signal violent fluctuation.

The installation of 3, stop valve and control valve

In order to make the above freezing downstream to set cut-off valve, and ensure no leakage.Control valves should be installed in the downstream, maintain high static pressure as far as possible, to prevent cavitation erosion and flash vaporization.

4, pulsation and vibration

For do not occur in the process and external mechanical vibration, asked the factory provided CMF resonant frequency range, to decide whether the pulsating or vibration frequency close to the resonant frequency.May consult factory on-site vibration situation whether to adopt the following measures, such as: 1) set up the pulsation attenuator, 2) setting vibration attenuator or flexible connection tube, 3) special flow address sensor clamp fixture, etc.

5, avoid the mutual influence between CMF

Same type two series installation, or more closely parallel (or parallel) installation, especially in the same support platform, the measuring tube vibration can make the mutual influence between each, the disturbance caused by the abnormal vibration, serious when the instrument will not work.When installation should take preventive measures, such as: stagger near the resonance frequencies of the instrument is proposed to the manufacturer;Flow sensor distance between, do not set on the same platform, independent setting racks;Flow sensor different direction installation;Flow sensor Settings between the antivibration material isolation method, etc.

6, pipeline stress and distortion

Flange and pipe flange connection and tighten bolts to uniform, do not produce stress (parallel to the plane of two flanges in the pipeline is not be caused by, for example).If when laying pipe spool connect people with the same length, can prevent bad cloth tube formation stress.In use process due to the process flow, pressure and temperature changes will be affected by tube spools or bending/twisting force to the force, effect measure performance, fixed support should be necessary.

7, the use of strong abrasive slurry

Mentioned above measuring strong abrasive slurry straight single pipe type and to make the sounding pipe in a vertical position, lest the wall wear not divide evenly, shorten service life.Wall thickness thinning, however, can reduce the measuring tube rigid and change the flow measurement value, so at the beginning of the this place running regularly monitoring, confirm the use cycle.

Measurement of tube wall fouling or deposit may also affect measurement accuracy, so regular cleaning.

8, zero drift and zero

Zero drift from the flow sensor part, the main reasons are: 1) the asymmetry of the mechanical vibration and damping;2) the density of fluid viscosity change.The influencing factors of the former are: a) the influence of pipe end fixed stress;B) vibration of pipe stiffness change;C) double resonance frequency inconsistencies;D) decay inside tube wall material.Which influence the cause of the zero is a structural imbalance, so even in atc when adjust the resonance frequency of the double tube is consistent, the zero drift may be produced when filled with liquid, the same vibration attenuation and frequency caused by low degree, also may produce zero drift in the flow.

Zero must be installed in the field, the flow sensor exhaust gas, full of stay current closed again after sensors upstream and downstream of the valve body, adjusted under the condition of close to the working temperature of zero.Installation of change or falling sharply change must be readjusted.

Eleven, flow range:

specifications | Nominal diameter | Flow range(t/h) | Working pressure limit | The zero stability | The velocity factor |

DN25 | 25(mm) | 1.6-16(t/h) | 4.0(MPa) | 0.002(t/h) | 1.0464(hm/ts) |

DN40 | 40(mm) | 4-40(t/h) | 4.0(MPa) | 0.003(t/h) | 0.3654(hm/ts) |

DN50 | 50(mm) | 6.5-65(t/h) | 4.0(MPa) | 0.006(t/h) | 0.2103(hm/ts) |

DN80 | 80(mm) | 16-160(t/h) | 2.5(MPa) | 0.01(t/h) | 0.0873(hm/ts) |

DN100 | 100(mm) | 25-250(t/h) | 2.5(MPa) | 0.015(t/h) | 0.0544(hm/ts) |

DN150 | 150(mm) | 55-550(t/h) | 2.5(MPa) | 0.02(t/h) | 0.0239(hm/ts) |

Twelve, appearance installation size:

model | Nominal diameter(mm) | Size and relevant size shape | Flange connection hole number | The weight of the(kg) | |||

L | H | B | D | ||||

DN25 | 25 | 472 | 481 | 96 | Phi 85 | 4 x phi 14 | 18.5 |

DN40 | 40 | 522 | 548 | 116 | Phi 110 | 4 x phi 18 | 25.5 |

DN50 | 50 | 597 | 606 | 137 | Phi 125 | 4 x phi 18 | 35 |

DN80 | 80 | 650 | 742 | 175 | Phi 160 | 8 x phi 18 | 53.5 |

DN100 | 100 | 714 | 820 | 198 | Phi 190 | 8 x 22 | 70 |

DN150 | 150 | 815 | 1029 | 265 | Phi 250 | 8 x phi 26 | 85 |

13, selection of coding:

instructions | ||

The type code | ZW-CMF | Mass flowmeter (wei measurement and control) |

Nominal diameter | 25...150 | DN25...........DN150 |

Special requirements | S(K) | Flange reducing (flaring) |

Ⅱ | Improved type | |

Nominal pressure | 2 / | 1.6MPa |

3 / | 2.5MPa | |

4 / | 4.0MPa | |

The accuracy of | 2 | precision0.2% |

5 | precision0.5% |

14, designing order selection guidelines:

1, products: specify model standard, if any, please live in wei and control sales hotline advisory prices, details!

2, technical support, if not specified product specifications, please put the working condition of requirements, design drawings, technical specifications, fax or email to us.

3, product orders for parameters: size (DN), nominal pressure (Mpa), temperature (℃), the connection way (thread, flange, etc.).

4, offer confirmation: the company provide price list and technical standard specifications to customers to confirm, in the technical aspects to confirm before you draw up a contract.

5, quality requirements, quality standards, the supplier is responsible for the quality conditions: according to the relevant state quality standards.

After-sales service commitment:

1, our company sold by mass flow series products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.