Aluminum alloy precession vortex flowmeter

ZW series - LUXAluminum alloy precession vortex flowmeterA new type of gas flow meter has the domestic advanced level.Set the flowmeter flow, temperature, pressure testing function can be in the work of the squeezing factor of temperature, pressure, automatic compensation, as well as local display in the measurement signal, can also be on-demand far eastone, have no moving parts, so for the average measurement is no mechanical wear, instrument management personnel without professional training, flow, pressure and temperature were measured and parameters can be read directly from the header and don't have to translate transformation;Realize the mechanical and electrical integration, daily without artificial unattended measurement process, process installation conditions are not strict, straight pipe upstream or downstream instrument can relatively large orifice meter big shorten, system measurement accuracy can meet the requirements of the current measurement of trade.

Second, the working principle:

ZW - LUX series aluminum alloy precession vortex flowmeter is when fluid by composed of spiral vane vortex generator, fluid is forced to around the dramatic rotating body axis, the formation of vortex.When fluid into the diffuser, vortex flow under the effect of reflux, began as a secondary rotation, form the gyro type vortex precession phenomenon.The precession frequency is proportional to the flow size, not influenced by the physical properties and fluid density.Detecting element quadratic spin precession frequency measured fluid, knew the traffic.And in a relatively wide flow rate range for good linearity.Flowmeter formula is: K = f/q

Type: K - l/m&sup 3 flow meter coefficient

F - vortex frequency Hz

Q - volume flow m&sup 3;/ s

The instrument coefficient of flow meter in certain structural parameters and the specified within the scope of Reynolds number and the fluid temperature, pressure, composition and physical properties (density, viscosity) has nothing to do.

Applications:

ZW - LUX series aluminum alloy vortex precession flowmeter adopts new micro processing technology, has the function of strong, wide flow rate range, simple operation and maintenance, and convenient to install and use etc, and the main technical indexes reach the advanced level of the same products abroad.It is widely used in petroleum, chemical industry, electric power, metallurgy, coal, etc all kinds of gas measurement.

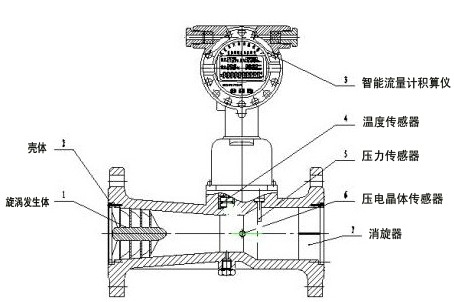

Four, vortex precession flowmeter by the following seven basic parts (figure 1) :

Precession vortex flowmeter structure

1, vortex occurred

Made of aluminum alloy, with a certain Angle spiral blade, it is fixed at the front of the housing contraction, forcing fluid produced strong vortex flow.

2, shell

Itself with the flange, the shape of the fluid channel and to a certain extent, according to the different working pressure and shell material can be cast aluminum alloy or stainless steel.

3, intelligent flowmeter integrating instrument

By the temperature, pressure testing analog channel, flow digital channels and micro processing unit, LCD driver circuit and other auxiliary circuit composition, and equipped with transmission signal interface.

4, temperature sensor

Pt100 / pt1000 platinum resistor as the temperature sensitive element, in a certain temperature range, the resistance value and temperature into corresponding relation.

5, pressure sensor

With diffused silicon piezoresistive type bridge road as the sensitive element, the bridge arm resistance will happen under outside pressure is expected to change, therefore under certain excitation current, its two outputs potential difference is proportional to the pressure.

6, piezoelectric crystal sensors

Near the shell expansion period of throat, can detect the frequency signal of vortex precession.

7, disappear is investigated

Fixed in the shell outlet, its function is to eliminate vortex flow, to reduce the impact on downstream instrument performance.

Five, the meter is composed of sensor and conversion display.

1, sensors, including vortex generator, detecting element, rectifier and shell.

Vortex generator is composed of specific spiral blade, it fixed in the housing contraction front, forcing fluid produced strong vortex flow.

The throat of detecting element near the expansion pipe with thermal, piezoelectric, strain, or optical detecting element to measure the frequency signal of vortex precession.

Rectifier is fixed in the meter body exports, its function is to eliminate vortex flow, to reduce the influence of downstream flow pattern for instrument measurement.

Shell design into a certain shape of flow channel, to form vortex, fixed and protection is installed in the internal parts and components, and by pipeline flange connection.

2, transform, display

By piezoelectric sensors detect the weak voltage signal after amplification, filtering, plastic into frequency is proportional to the flow of the pulse signal, and then by the display counter.Display is equipped with a transmission interface, the output signals.To measure gas medium temperature and pressure compensation, can be converted into standard volume flow conditions, and display.

Technical features:

1, the circuit USES surface-mount technology, compact structure, high reliability;

2, adopting micro power consumption of new and high technology, with internal and external power supply can work, the machine power consumption is low;

3, using high-performance microprocessors and modern filtering technology, software powerful, superior performance;

4, no mechanical moving parts, good stability, not easy corrosion, without mechanical maintenance;

5, straight pipe before and after the demand is low, the former 3 or higher dn, after 1 or more dn.

6, the high contrast LCD display, can display the cumulative flow and transient flow, the reading is convenient, clear and intuitive;

7, instrument has password function, prevent illegal setting;

8, instrument has the function of outage data;

9, new display flow value, and with a pulse signal, and (4 ~ 20 mA) standard analog signal is transmitted out, facilitate and secondary instrument connections.

Seven, the main features:

1, built-in pressure, temperature, flow sensor, safety performance is high, compact structure, beautiful appearance;

2, in situ show that temperature, pressure, the instantaneous flow and cumulative flow;

3, a new signal processing amplifier and unique filtering technology, effectively eliminate the pressure fluctuation and pipeline vibration produced by the jamming signal, greatly improve the anti-interference ability of the flowmeter, small flow have excellent stability;

4, the characteristic time display and real-time data storage function, no matter what circumstance, can guarantee the internal data is not lost, may be retained * sex;

5, the machine power consumption is extremely low, can run on battery power for a long time in, is the ideal without external power supply on-site display instrument;

6, anti-theft functions and reliable, with password protection, prevent parameter changes;

7, free rotation headers can be 180 degrees, convenient installation.

Eight, the technical parameters:

1, flowmeter specification, basic parameters:

specifications | Nominal diameter DN(mm) | Flow range (m3/h) | Instrument coefficient (m3)- 1 | Classes. (MPa) | The accuracy of | For note |

ZW-LUX-25 | 25 | 2.5 ~ 30 | 240000 | 1.6; 2.5; 4.0. | 1.5 on the Richter scale | PN 1.6 MPa or less for the aluminum alloy shell; PN 4.0 MPa or less for the stainless steel shell; PN > 4.0 MPa for special specification, Please specify when ordering. |

ZW-LUX-32 | 32 | 4.5 ~ 60 | 90000 | |||

ZW-LUX-50 | 50 | 10 to 150 | 24000 | |||

ZW-LUX-80 | 80 | 28 ~ 400 | 4800 | |||

ZW-LUX-100 | 100 | 50 ~ 800 | 2800 | |||

ZW-LUX-150 | 150 | 150 ~ 2250 | 680 | |||

ZW-LUX-200 | 200 | 360 ~ 3600 | 210 |

Note: a. the flow range of products listed in the table when the verification of the flow range (temperature, air pressure medium for P = 1.205 Kg/m3);B. with the increase of pressure, flow range is expanding.

2, the standard state situation: P = 101.325 kPa, T = 293.15 K;

3, the conditions of use:

A, environmental temperature: - 30 ~ + 60 ℃;

B, medium temperature: - 20 ~ + 80 ℃;

C, relative humidity: 5% ~ 95%;

D, atmospheric pressure: 86 kpa to 106 kpa.

4, electrical performance indicators:

Outside a, working power supply: power supply: + 24 VDC;

B, within the power supply: 3.6 V lithium batteries;

C, the whole machine energy consumption: external power, < 1 w power supply, < 0.3 mW, lithium battery can be used at least 2 years;

D, the output mode: frequency signal;

: e, 4 ~ 20 ma current signal corresponding to the flow of 0 ~ Qmax, 20 ma, corresponding flow can be set by users themselves;

F, RS485 communication: can transfer temperature, pressure, the instantaneous flow and cumulative flow parameters;

5, explosion-proof marks: Exd Ⅱ BT4;

6, protection grade: IP65.

Nine, installation instructions:

Can work in normal condition, in order to make the flowmeter installation personnel must understand on the instrument of the concrete structure, characteristics and traffic signal conversion, understand the role of each link in the process of signal transmission, according to the product manual for installation.In general precession vortex installation using the following points should be paid attention to.

1, choose reasonable installation place.The installation site should avoid strong electric power equipment, high frequency equipment, strong power switch;Avoid high temperature heat source and radiation of heat;Avoid high temperature and strong corrosive atmosphere influence: avoid strong vibration and installation, wiring, maintenance party then.In the upstream and downstream sensors, must eliminate the long pipeline vibration generated by moving.

2, general requirement level installation, by the flow of current body should be consistent with refers to the flow arrow on the shell.Can be installed vertical or inclined.When the liquid should be sure sensor is completely filled with liquid.In order to does not affect the normal fluid loss, maintenance Suggestions in the installation of the instrument and add bypass.

3, low requirement for straight pipe before and after, in principle don't need a straight pipe before and after the flowmeter is allowed, but general requirements before the instrument has 3 d length of straight pipe, instrument after 1 d length of straight pipe.Special circumstances require 5 d and 3 d length.When a single or double bend bend pipe bending radius is greater than 1.8 D, flowmeter can don't straight pipe before and after.Under the condition of various pipe installation of straight pipe length such as required.

Falling in to 4, measuring gas or steam can be used when the degree of pressure compensation, the installation position of thermometer and pressure gauge.

5) when the current body contains impurities, in front of the instrument should be loaded already device or on a screen, but still should guarantee the straight pipe in front of the instrument.

6, measuring a small amount of heterogeneous gas liquid two phase flow sensor installation method.Measuring liquid, there may be a small amount of gas phase in the pipeline, its content does not exceed the prescribed gas liquid two phase fluid, so as to prevent gas stranded inside the sensor, you must install gas separator.When measuring the amount of gas, when the pipe is measured condensate gas may be produced, and gas exist in unstable liquid phase was not removed, in order to prevent fluid retention, vertical installation within the sensor.Fluid when measuring high and low temperature sensor itself should be effective guarantee measures.

7, instrument measured by measuring the volume of a gas flow for the actual flow of the gas being measured work condition.If the actual flow conversion into standard state of flow, can press type calculation type, 4?P is a standard volume flow conditions;4, it is the working status of the volume flow amount;Ho is the absolute pressure of the gas being measured standard condition;To the thermodynamic temperature of the gas being measured is a standard condition;The household is work state, the absolute pressure of the gas being measured;T is the working status the thermodynamic temperature of the gas being measured;Z is the compressibility of the gas being measured work condition.

8, when the pipeline is longer, vibration may occur when the fixed bracket should be installed at upstream and downstream flow meter, prevent the pipeline vibration.According to the experience, the flow measurement value vulnerable to air flow pulsation and pressure changes.

9, volume flow meter coefficient K.vn and mass zui flow meter coefficient K,,, o is established in the state of normal temperature calibration instrument before they leave the factory.Instrument working status and laboratory calibration status is large, the instrument coefficient K, and K 'correction should be done on the instrument coefficient correction method is the same as the vortex flowmeter.

Ten, installation note requirements:

Click the flow mark 1, sensors can be tilted in vertical, horizontal, or any location on the installation;

2, when the pipeline vibration source is longer or distance is relatively close, support should be installed at upstream or downstream of flowmeter, in order to eliminate the influence of the pipeline vibration;

3, sensor installation location should have enough space, so that the flow meter inspection and maintenance, and should meet the environmental requirements of flowmeter;

4, should avoid the disturbance of external magnetic field;

5, when used in outdoor installation, should have cover, avoid the strong sunlight and rain erosion, affect the service life of the instrument;

6, when the pipeline pressure testing, should pay attention to the configured intelligent flowmeter pressure pressure sensor measuring range, in order to avoid over-voltage damage pressure sensor.

Installed 7, should pay attention to stress, the effect of upstream and downstream piping flow meter should be coaxial, otherwise it will produce shear stress.The location of the installation flowmeter should consider the thickness of the sealing gasket, or install a elastic expansion joints in the downstream side.

Should be clear before 8, installation flow meter of the pipeline welding slag and other sundry.

9 and put into operation, should slowly open flowmeter, downstream of the valve, in order to avoid air flow is too sharp and blunt bad on the moment.

10, when the meter requires signal remote transmission, electric performance indicators should be in strict accordance with the "" request access external power (8 ~ 24 VDC), it is strictly prohibited in the direct access to 220 vac or 380 vac signal output power;

11, the user may not change the connection mode of explosion protection system and arbitrary twisted each output pin connector;

12, flow meter is running, not allowed to open the rear cover change instrument parameters, otherwise the normal operation of the meter;

13, regularly check the flowmeter flange leakage situation.

Eleven, matters needing attention:

In order to better use ZW - LUX series, attention should be paid to the following:

1, the right selection:

Selection should grasp the two basic principles in the process, to ensure the production safety, second, we must ensure the accuracy.To do this, we must to carry out the selection of the three parameters, namely the immediate and long-term zui, zui small and common instantaneous flow (mainly used for the size of the selected instrument specifications), the design of the measured medium pressure (mainly used for the selected nominal pressure level meter), the actual working pressure (pressure level) is mainly used for the selected instrument pressure sensors.

2, before using the calibration:

In order to ensure that the instrument in the future work in the process of the measurement result is reliable and accurate, should be in formal before installation to be sent to the detection capability and qualification of authorities, conduct a verification system of the whole flow range.

3, pay attention to the installation:

Although this kind of instrument for process installation and use of the special requirements of environment is not too much, but any kind of flow measurement instrument has some common, such as far as possible avoid the vibration and the high temperature environment, away from the flow interference elements (such as compressor, separator, pressure regulating valve, reducer, and pipe, elbow, etc.), keep straight pipe before and after the meter wall smooth and flat, ensure to clean single-phase fluid measured medium, etc.

4, the late management:

In order to ensure the accuracy, reliability of meter long (to avoid unexpected shutdown and loss of data), should be system calibration on a regular basis (every 1 ~ 2 years), transcribing header data (daily or weekly), change the medium parameters (monthly or quarterly) and not regularly check the battery status, check the instrument coefficient and seal etc.

5, internal maintenance:

Temperament of dirt or other reasons, the need for measuring cavity and its components of instrumentation for regular inspection and cleaning.One thing must pay special attention to: for the same specifications of the vortex precession flowmeter, the vortex core components such as body, diversion and are not interchangeable.Otherwise, he must calibration instrument measurement coefficient and the matching of the temperature and pressure sensor calibration system.

Twelve, flange connection size:

Nominal diameter DN(mm) | Nominal pressure (MPa) | Overall dimensions (mm) | The table body material | The weight of the (kg) | ||

The length of the table L | Height H. | Stainless steel | Aluminum alloy | |||

20 | 4.0/1.6/2.5 | 180 | 347 | Square root | 5 | |

6.3, 10, 16 | 180 | 357 | Square root | |||

25 | 4.0/1.6/2.5 | 200 | 367 | Square root | 7 | |

6.3, 10, 16 | 200 | 378 | Square root | 10 | ||

32 | 4.0/1.6/2.5 | 230 | 383 | Square root | 9 | |

6.3, 10, 16 | 230 | 402 | Square root | 12 | ||

50 | 4.0/1.6/2.5 | 230 | 403 | Square root | 11 | |

6.3, 10, 16 | 260 | 421 | Square root | 14 | ||

80 | 1.6 | 330 | 438 | Square root | 11 | |

2.5/4.0 | 330 | 438 | Square root | 18 | ||

6.3, 10, 16 | 330 | 446 | Square root | 21 | ||

100 | 1.6 | 410 | 468 | 14 | ||

2.5/4.0 | 410 | 475 | Square root | 18 | ||

6.3, 10, 16 | 410 | 483 | Square root | 33 | ||

150 | 1.6 | 585 | 542 | Square root | 21 | |

2.5/4.0 | 585 | 549 | Square root | 52 | ||

6.3 | 585 | 572 | Square root | 72 | ||

200 | 1.6 | 700 | 618 | Square root | 41 | |

2.5 | 700 | 626 | Square root | 117 | ||

13, selection of coding:

Code name | CAL | Flow rangem3/h | ||

ZW-LUX-25 | DN25 | 2.5~30 | ||

ZW-LUX-32 | DN32 | 4.5~60 | ||

ZW-LUX-50 | DN50 | 10~150 | ||

ZW-LUX-80 | DN80 | 28~400 | ||

ZW-LUX-100 | DN100 | 50~800 | ||

ZW-LUX-150 | DN150 | 150~2250 | ||

ZW-LUX-200 | DN200 | 360~3600 | ||

Code name | function1 | |||

N | No temperature pressure compensation | |||

Y | With temperature compensation | |||

Code name | Output type | |||

F1 | 4-20mAOutput (two-wire system) | |||

F2 | 4-20mAOutput (three-wire system) | |||

F3 | RS485Communication interface | |||

Code name | function2 | |||

E1 | 1.0level | |||

E2 | 1.5level | |||

T | The normal temperature | |||

P1 | 1.6Mpa | |||

P2 | 2.5Mpa | |||

P3 | 4.0Mpa | |||

N1 | internal3.6VThe power supply | |||

N2 | DC24VThe power supply | |||

W1 | Stainless steel | |||

W2 | Aluminum alloy | |||

14, designing order selection guidelines:

1, instrument selection, as far as possible not to use the work flow in the lower limit value, so the meter diameter should be as small as possible, in order to obtain a larger flow rate and flow range.

2, the flowmeter should be used in the technical parameters of medium pressure and temperature range.Don't deliberately choose the high pressure level and ultra-high temperature instrument, should be selected according to the actual work pressure and temperature instruments, which had higher prices.

3, in the explosive dangerous location, should choose explosion-proof type flowmeter.

4, the lower limit of flowmeter flow depends on the operation condition of the medium density and kinematic viscosity, the maximum flow is generally not affected by medium pressure and temperature, so to determine the flow range as long as you determine the actual minimum flow can be available.Calculate the minimum flow rate, flow range check table to determine the appropriate diameter.

After-sales service commitment:

1, our company sold by flow meter series products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.