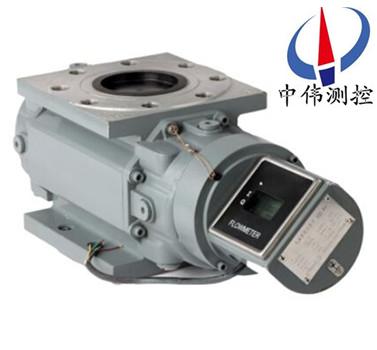

Roots flowmeter

Productoverview:

ZW-LLQ series Roots flowmeter Mainly used for high precision measurement instrument for continuous or intermittent measurement of fluid flow in pipes. It has the characteristics of high precision, good reliability, light weight, long service life, low noise, convenient installation and use. The scene indicates the cumulative flow, instantaneous flow, single volume, but also the output pulse signal, 4-20mA or 1-5V analog signal, 232485 communication, 4-20mA+HART protocol, MODBUS etc..

Second, working principle:

The ZW-LLQ series is <strong> a Roots flowmeter</strong> when the measured gas into the inlet end, drives the rotor to rotate, rotates a circle will be discharged from the export volume, this is the rotating fixed displacement principle. The rotation of the rotor by magnetic coupler transmission output rotational frequency, to achieve the purpose of measuring or testing flow. At the same time, the structure of different forms, can meet the different requirements of users.

Dual display type: at the same time with mechanical counter and flow compensation apparatus by the mechanical counter display condition accumulation, at the same time by the flow compensation instrument for temperature and pressure correction, direct detection showed that the medium temperature, pressure, flow, and the total working volume and total volume flow condition detection standard.

Third, application:

ZW-LLQ series <strong> Roots flowmeter</strong> using powerful new microprocessor, high computing accuracy, reliable performance, low power consumption, and power supply automatic switching, lithium batteries can be used more than 5 years. Widely used in petroleum, chemical, electric power, metallurgy, industrial and civil boiler gas metering and city gas, gas station measurement and gas trade measurement etc..

Fourth, the main features:

1, high precision, good repeatability. The internal rotor by the precision machining and balance test, contact free rotation, good lubricating oil, ensure the accuracy of flowmeter unchanged, long working life.

2, before and after the flowmeter does not require straight pipe, can be installed in a narrow environment.

3, small starting flow, wide range, suitable for measurement of gas flow with large changes.

4, the measuring accuracy is not affected by the pressure and flow changes, stable performance, long service life.

5, good versatility, all accessories can be used in general roots flow sensor.

6 configuration, RS-485 communication interface and IC card dedicated signal concentrator supporting, and through the GPRS/CDMA, Internet, 7, Monitor System network composed of remote data acquisition machine, centralized management for data acquisition and real time.

8, surface mount circuit in the installation process, compact structure, strong anti-interference ability and high reliability.

9, a high performance microprocessor and digital filtering technology, powerful software, superior performance.

10, the floating-point and 5 meter coefficient and automatic correction, fault diagnosis and alarm function.

11, micro power technology, internal and external power supply, low power consumption, with only one 2#3.6VDC lithium battery, can work continuously for more than 5 years.

12, local display flow values, and multiple signal output function.

13, the high contrast LCD display, can display the standard cumulative flow, standard volume flow, volume flow conditions, the percentage of 14, medium temperature, pressure value and battery usage percentage, and with Chinese prompt.

15, with real-time data storage function, explosion-proof symbol is ExibllCT4 GB.

16, shell protection grade IP65 flowmeter.

Five, technical parameters:

1, measurement of fluid: natural gas, gas, inert gas, air and other gases;

2 caliber series: DN25, 32, 40, 50, 80, 100, 150, 200;

3, accuracy: ordinary type intelligent type: + 1.5% + 1%;

4, the repeatability is less than the absolute value of basic error limit: 1/3;

5, range: 20; 1-120:1 (Zui width);

6, electrical interface: M20X1.5;

7, protection grade: IP65;

8, explosion-proof grade: ExiaIICT4;

9, shell material: Aluminum Alloy.

Six, the use of environmental conditions:

1, the environment temperature: -30 -+70 DEG c;

2, medium temperature: -30 degrees C - +85;

3, relative humidity: 5% ~ 95%;

4, air pressure: 70kPa-106kPa;

5, nominal pressure: 0.5, 1.OMPa;

6, pipe connection: flange connection;

7, installation: horizontal and vertical;

8, power supply: 3.6V lithium battery, DC18V - DC30V;

9, straight pipe requirements: upstream downstream 3D 2D valve (D meter diameter) except;

10, communication protocol: RS485/RS232C;

11, the output signal: 4 ~ 20mA current mode, pulse signal, the battery voltage alarm signal, alarm signal flow;

12, electromagnetic compatibility: the power in the double isolation and anti 10ms + 500V + 24V to prevent the impact of strong interference, power supply, communication port has the wrong connection RS-485 transient voltage suppression, anti lightning, anti shock, anti electrostatic discharge 500V, 10ms interference impact;

13, control signal output: upper and lower limit alarm, alarm valve and battery voltage alarm;

14, real-time data storage function: stop recording, recording, recording time interval diary.

Seven, equipment are as follows:

1, in order to reduce the error of additional meter, can automatic temperature compensator selection and flow of juice and automatic pressure compensator.

2, in order to facilitate control and management, can choose a flowmeter with various signal output function and integrating instrument, with the support of the recorder and the controller and special computer equipment etc..

3, in order to make the flowmeter normal safe operation, can use additional equipment such as flowmeter, in order to filter the fluid in the debris, to install the appropriate filter or sediment in front of flowmeter when necessary; in order to prevent the installation of pressure fluctuation, buffer tank, expansion chamber safety valve or gas protection device in the flowmeter when necessary; for the safe operation of the flowmeter also, the system should be equipped with reliable pressure and flow control equipment, the system pressure and flow are not exceed the upper limit value of flowmeter.

In summary, in order to make use of the flowmeter can high accuracy measurement, high reliability, the main factors that should be considered when choosing a:

1, the flow rate range is continuous or intermittent measurement measurement.

Range 2, temperature, pressure, Zui high work pressure and allow the pressure loss.

3, the measured characteristics and types of media, such as viscosity, corrosion resistance, entrainment quantity and size etc..

4, the required accuracy, whether the requirements for showing the value of temperature and pressure compensation.

5, site installation conditions.

6, maintenance and operation cost.

7, check meter method etc..

Eight, installation requirements:

1, environmental conditions: no corrosive fluids, small mechanical vibration, less dust and place away from heat. For a volume correction instrument of intelligent flowmeter, should also comply with the provisions of the environment.

2, the ambient temperature: not more than -20, the range of +8O DEG C.

3, the pipeline conditions: installation in front of flowmeter, piping must be cleaned and purged, remove all debris, rust and dirt. Connecting pipe should be in accordance with the import and export of the same caliber flowmeter axis, may not have bulges protruded convex wall in the pipeline. Flow meter should take the stress free installation, considering pipe work caused by temperature stress.

Nine, installation notes:

1, before installation shall not open the inlet flow, the outlet seal two;

2, when the pipe is installed on many devices, should be installed in the flowmeter zui;

3, where conditions permit, the pipeline must be high pressure purge before installation;

4, the installation should at the interface of iron pins, careful removal of burr;

In front of the 5 meter must be installed, filter, filter media measurement; measurement of liquid, if containing gas, optional getter device flowmeter, ensure the measuring precision of flowmeter;

6, installation modes, horizontal vertical installation can be installed vertically progress under the lower upper is not affected, but the meter shall not be reversed, anti loaded, opposite directions, waist wheel reversal, because the rotation between different gap design will damage the waist wheel;

7, on the lower straight pipe section, but must set aside to install filtering device enough distance;

8, the waist wheel rotation by fluid pressure is the force of viscous medium, when the measurement is too high, affect the measuring precision of flowmeter;

To avoid the above points, the measurement precision can achieve better flowmeter.