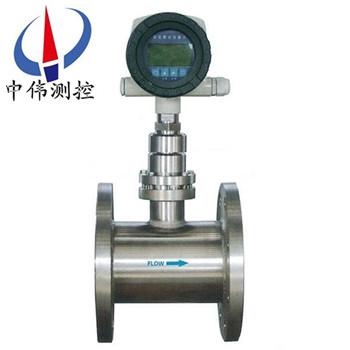

Target type flowmeter

I. product overview

Zw-bsl series target flowmeters have been applied in industrial flow measurement since 1960s. They are mainly used to solve the flow measurement of fluid with high viscosity and low Reynolds number. They have experienced two development stages of pneumatic meters and electric meters. Zw-bsl series is a new type of flow meter, which is developed on the basis of the original measuring principle of strain gauge type target flowmeter, and adopts the new type of capacitive force sensor as the measuring and sensitive transmission element, and at the same time USES the modern digital intelligent processing technology.

Using capacitive force sensor is the new product key core to realize high precision, high stability, completely changed with strain chip target flowmeter temperature drift is big, poor ability to resist overload (shock), some shortcomings such as static sealing points, not only played a target flowmeter the original technical advantages, at the same time is comparable to those of volumetric flowmeter measurement accuracy, together with its unique anti-interference, impurity resistance, in addition to substitute for conventional flow measurement can measure flow problems, Especially in small flow, high viscosity, easy to coagulate and block, high temperature, low temperature, strong corrosion, strong vibration and other flow measurement difficult conditions have good adaptability.

Ii. Structure and working principle

1, structure,

Zw-bsl series target flowmeters are mainly composed of measuring tube (housing), new type sensor (including choke element), integrated display and output parts. Suitable sensors must be selected according to different media and working conditions. Therefore, accurate measurement objects and parameters provided by users and appropriate sensors selected by manufacturers are the key to accurate measurement of products.

2. Working principle

When medium in the measurement of pipe flow, because of its kinetic energy and target plate pressure difference, and produce on the target plate force, make the target board of trace amounts of displacement, the force is proportional to the square of the velocity with the media, the size of the target plate force of the target bar transfer, make the sensor elastomer produces trace changes, thereby breaking patches of capacitance bridge balance. Generate voltage signal corresponding to the force of flow on the target plate: influenced by the fluid flow characteristics, the flow is proportional to the square of the voltage generated by the bridge. Its mathematical expression is as follows:

CdA rho/V2 / F = 2

Where: the force (kg) exerted on F flow arrester

The drag coefficient of the Cd object

A axial projection area (mm2) of flow arrester on measuring tube

Rho medium density on condition (kg/m3)

Average velocity of V medium in measuring tube (m/s)

The force F received by the choke (target) is transmitted to the sensor through the rigidly connected transmitter (measuring rod), and the sensor generates voltage signal output: V=KF

Where: V -- voltage (mV) output of the sensor, K -- proportionality constant, F -- force (kg) on the choke (target),

After the voltage signal is preamplified, AD converted and processed by computer, the corresponding instantaneous flow and cumulative total amount can be obtained.

Iii. Application:

Zw-bsl series target flowmeters can replace the flow measurement problems that can be measured by conventional flow, especially in the flow measurement problems that are difficult such as high viscosity, dirty medium, easy to coagulation and blockage, high temperature, low temperature, strong corrosion and so on. Widely used in petroleum, chemical, energy, food, environmental protection, water conservancy and other fields. From the effect after its use, it has a very broad applicability, that is:

1, suitable for all kinds of pipe diameter: from 15-2000 mm Φ Φ to bigger.

2, suitable for high and low temperature medium: from - 196 ℃ ~ + 450 ℃.

3, suitable for high pressure conditions: from 0 to 42Mpa (surface pressure).

Iv. Main features:

1. Sensors are immovable parts with simple and firm structure;

2, the application range and adaptability is very wide, general industrial process in the fluid medium, including liquid, gas and steam, diameter range (DN15 above), various working conditions (high, low temperature, atmospheric pressure, high pressure) can be applied, it can be said that its application range can be compared with the orifice meter beauty.

3, high accuracy, the total measurement can reach 0.2%R;

4, wide range, 4:1 ~ 15:1 to 30:1;

5, can solve the difficult flow measurement problems, such as measurement containing impurities (particles) and other dirty fluid; Crude oil, sewage, high temperature residues, slurry, burnt alkali liquor, asphalt, etc.;

6, high sensitivity, can measure small flow, the flow rate can be as low as 0.08m/s;

7, for small diameter (DN15 ~ DN50), low Reynolds number (Red=103 ~ 5 103) fluid, it can make up for the standard throttle device is difficult to apply occasions, such as small diameter steam flow measurement;

8, can adapt to high parameter measurement of fluid, pressure up to tens of MPa, temperature of 450 ℃;

9. It can be used for the measurement of bidirectional flow fluid;

10. Low pressure loss, about half of the standard orifice;

11. Strong ability to resist the interference of upstream choke, and the length of the upstream straight pipe is generally 5-10d;

12. Dry (weight method) calibration can be adopted to bring convenience to user cycle calibration;

13, direct reading instrument without external energy, clear, easy to operate, can also output standard signal (pulse frequency or current signal);

14, the meter performance and price is high, economical flow meter;

15. Easy installation and maintenance.

V. technical parameters:

1. Measurement range 0-400t/h;

2. Accuracy grade: 0.5% FS 1.0% FS 2.0% FS;

3. Output signal: the output of 4-20ma two-wire system has a linear relationship with the flow;

4. Power supply voltage: 12 ~ 36VDC;

5. Nominal pressure: 1.6 2.5 4.0 6.4MPa;

6, environment temperature: - 30 ℃ ~ 60 ℃ (special: - 40 ℃ ~ 80 ℃).

7, medium temperature: regular 100 ℃ or less (no heat sink);

Type of high temperature of 400 ℃ or less (with heat sink);

8. Material of receiving liquid: carbon steel or 1Cr18i9Ti; The rest were 1Cr18Ni9Ti.

9. Shell material: cast aluminum;

10, flange standard: DIN2501 special type by the user choice;

11. Cable interface: M20*1.5 (internal thread);

12. Protection level: IP65;

13, load characteristic: zui big load resistance (supply voltage - 12) = = 50 * 600 Ω @ 24 v;

14, alarm output: collector open circuit, zui large input current 100mA, zui large switching voltage 30VDC, with deviation control;

15. Pulse output: small pulse width of 50ms, dual output;

16, zui large accumulated flow display value of 50000 units, automatic reset;

17. Damping time: adjustable from 1 to 100 seconds;

18. Explosion proof form, mark and certificate no.

Vi. Precautions for installation and use

(1) installation precautions

1. There should be straight pipe sections before and after the measuring pipe. The diameter of the straight pipe section should be equal to that of the flow meter measurement pipe. The length of the straight pipe segment on the upstream side of the flowmeter is generally not less than 6~20D. It is determined according to different types of upstream choke, and the length of the straight pipe segment on the downstream is not less than 3-4d. The flowmeter is usually calibrated at the horizontal position and is usually installed in the horizontal pipeline. When it must be installed in the vertical pipeline, the flowmeter must be calibrated at the vertical installation state with the hanging weight method, and the direction of the fluid should be from bottom to top.

2. In order to facilitate maintenance and prevent unidirectional force when the flowmeter is put into use, parallel installation of the discharge pipe downstream of the bypass pipeline flowmeter is necessary to facilitate instrument cleaning and purging, especially for measuring dirty fluid or medium that is easy to solidify and crystallize. The target plate and measuring tube (gauge body) should be installed in the same axis. According to the test on a certain caliber, if the center of the target plate and the center of the pipeline deviate from 1mm up and down, it may cause a deviation of 1% to 2% of the flow coefficient, but the influence is not obvious if the deviation is 1mm from left to right.

3, the installation of explosion-proof target flow timing, should pay attention to check whether there is explosion-proof mark and explosion-proof certificate, explosion-proof equipment is in good condition.

4. For small-diameter flowmeter, because the pipe diameter is small and the flowmeter is relatively heavy, in order to prevent pipe deformation or vibration during work, a support should be set to support the flowmeter. It is not necessary to set support for large diameter flowmeter.