Plate type ultrasonic flowmeter

Products overview:

ZWS - 100 - f seriesPlate type ultrasonic flowmeterIs imported, integrated circuit pasted on the circuit complete digitization, integration, and improve the measuring accuracy and stability, greatly reducing the breakdown maintenance, is the current domestic advanced technology, stable performance zui, easy installation of a low power flow measuring instrument, according to many years of experience, and constantly updated products, currently ZWS - 100 - f series of its powerful functions, operation speed, strong anti-interference ability, cycle sampling frequency up to 128 times, are widely used in industrial field of online measurement of various kinds of liquid flow rate.

Second, the working principle:

ZWS - 100 - f seriesIn tray type ultrasonic flowmeter by using the theory of measuring the ultrasonic transmission time in the pipeline.Medium (liquid) flow velocity in the pipe, and a lag between the time of ultrasonic propagation along the downstream and upstream of medium with linear relationship.As long as measure the ultrasonic propagation time of downstream and upstream respectively, can be obtained on the basis of the linear relationship at various points along the pipeline route on the velocity of the instantaneous average flow velocity.In this way, the medium flow can be obtained by flow rate, pipe cross-sectional area and the Reynolds number.

When ultrasound beam propagation in the liquid, the flow of the fluid produces small changes will make the travel time, and the propagation time of change is proportional to the liquid flow rate, which can calculate the flow rate of the liquid.

Applications:

ZWS - 100 - f seriesIn tray type ultrasonic flowmeter can measure the fluid is water, sea water, or oil, uniform liquid slurry, conduct electricity or not, corrosive or no corrosive liquid can be measured.It is widely used in tap water, sewage treatment, heating system, petrochemical, power plants, mining, paper making, steel mills, air conditioning billing, etc.

Four, the main features:

1, high reliability, high performance, good applicability, full display in Chinese.

2, day, month and year flow accumulation function, can record run 64 days before the operation, the first 64 months, the first five years of accumulated flow operation.

3, on, power management function, can record, electricity and traffic on 64 times before, can be manually or automatically compensate to reduce flow losses.

4, effectively overcome the wall of the ultrasonic signal attenuation and the rough surface of the pipe to scattering of ultrasonic signal from surface reduce the energy consumption of ultrasonic signal.

5, improved flow measurement accuracy, especially suitable for pipe flow measurement.

6, unique disassembly with pressure, does not affect the normal production, at any time to complete the on-line replacement and maintenance.

Five, the technical parameters:

1, the accuracy is better than 1%, the repeatability is 0.5%;

2, for 500 ms measurement cycle;

3, backlit LCD can display instantaneous flow and cumulative amount at the same time, the instantaneous heat and accumulative total quantity of heat, velocity, time and other data;

4, 4 ~ 20 ma output current, or 0 to 20 ma, such as impedance 0 ~ K, accuracy of 0.1%;

5, which can realize heat measurement or one dual purpose;

6, automatic recording, 64 month before, 64 days before the five years of accumulated flow;

7, automatically record before 64 calls and interruption time and flow rate, can be manually or automatically fill amount, reducing the loss of user traffic;

8, automatic record 64 days before the working state of the flow meter is normal;

9, the data interface to factory is configured to RS - 232, equipped with RS - 232 / RS - 485 converter can be turned into RS - 485.

Six, directions for use:

1, zero flow rate checks

Around when the pipeline fluid static, without strong magnetic field interference, strong vibration, header shows zero, automatically set zero point at this time, eliminate the zero drift, the runtime must to remove small signal, usually 5% flow is less than the full process flow, automatic removal.Zero at the same time also can adjust menu.

2, instrument panel keyboard operation

Before start the meter running, the first to set parameters effectively, for example, using the system, installation, pipe diameter, pipe wall thickness, pipe material, pipe roughness, fluid type and the distance between two probes, velocity of flow unit, zui small speed, large zui, etc.All parameters input correctly, instrument can display correctly the actual flow value

3, flowmeter calibration

Guarantee the accuracy of flowmeter, we conduct regular check, usually we use higher precision direct comparison, portable flowmeter: using the test data to compute error = - standard/standard measurements, using relative error calculation, correction factor, satisfy error of measurement error of plus or minus 2%, can meet the measurement requirements.This simple and convenient operation, can effectively improve the accuracy of measuring.

Seven, special cable:

Models for SEYV75-2 block type, single can be extended to 500 meters, at the same time, pay attention not to parallel with high voltage cable, as far as possible to avoid the frequency converter.

Eight, pipes:

1, pipe: steel, stainless steel, cast iron, cement pipe, PVC, aluminum, copper, glass fiber reinforced plastic all quality of pipes, such as the lining is allowed

2, pipe inner: 15 mm to 6000 mm;

3, straight pipe sensor installation points to meet the upstream 10 D, 5 D, downstream from pump discharge 30 D refers to the diameter (D).

Nine, working environment:

1, the temperature of the host: - 30 ℃ ~ 80 ℃;

2, flow sensor temperature: - 40 ℃ ~ 160 ℃;

3, temperature sensor temperature: selected according to user's requirements;

4, host, humidity: 85% RH;

5, flow sensor, humidity: can work immersed depth of 3 m or less;

6, disc type ultrasonic flow power: AC220V DC8 ~ 36 v or AC7 ~ 30 v.

Ten, measuring medium:

1, type: tap water, sea water, industrial sewage, various oil, acid alkali, alcohol, beer can support such as ultrasonic single homogeneous liquid;

2, temperature: 0 ℃ ~ 160 ℃;

3, turbidity, 10000 PPM or less, and the bubble content is small;

4, velocity: 0 ~ + 30 m/s;

5, flow: positive and reverse bidirectional measurement, and can be measured net flows.

Eleven, sensor installation steps:

1, choose to have enough length of straight pipe position, is a new pipeline, no rust, easy to operate.

2, clear the clutter and on the pipeline corrosion, using grinding Angle grinder abort rust.

The launch of 3, the sensor surface with plenty of coupling agent (such as butter, vaseline, etc.), besmear decoupling.

4, the purpose of the mixture is ruled out sensor emission surface and air between the external surface of the pipe.

5, special remind: should avoid sand and debris into the middle.

6, horizontal pipe wall upside may remain some bubble, in the selection of pipe should be installed on the tangent to the pipe on the side of a vertical surface.

Twelve, check the installation:

Users after installed sensors to inspection on the following items: receive signal strength and goodness of Q value, jet lag, estimates the liquid velocity and ratio of signal transmission time.Only in this way can flow meter and stable operation, accurate measurement.

13, signal intensity:

Refers to the received signal strength after amplification of ultrasonic signal amplitude, with 3 digits said: [000] is not detected any signal;Z [999] refers to the received signal.

Although the signal between 500-999 meter can work, but the stronger signal strength can get good results, so users should adjust the signal of the sensor to receive to z.

Suggestions according to the following methods of operation to get larger signal strength:

1, if measured flow numerical instability, when signal strength is below 700, to choose a better location measurement.

2, the outer surface of the polishing pipe carefully, some slightly more coupling agent.

3, slightly adjust the relative position of the sensor at the same time observe the flow meter of received signal strength, parked in the signal zui big place, at the same time also want to check if the distance between the sensor can satisfy the demands of M25 window display.

Signal quality (signal good degrees) :

Flowmeter signal quality is to use Q value.Q value means the higher signal-to-noise ratio (SNR) of an acronym, of course, is more accurate, the measured data of the Q values should be between 600-900 range, the higher the better.

14, notable matters of installation:

1, the liquid must be full of pipes, find out and accurately input pipe diameter, material, wall thickness, the lining material and lining thickness pipe related parameters.

2, transducer, the straight pipe before and after when installation should at least meet the requirements of before 10 d after 5 d, avoid the pipe at the top and bottom, as far as possible in the horizontal position of the pipeline installation, or with a diameter of 45 °, pay attention to avoid weld.

3, according to the installation of the flowmeter calculated from installing a transducer, and comprehensive reference flowmeter signal intensity, measured the speed of sound value, signal quality parameters such as distance, installation, inspection, adjust the transducer installation location to the ideal position.If the meter measured velocity value and the actual sound velocity is more than + / - 6 m/s, flow meter measured flow value and the actual flow value also can appear difference.

4, flowmeter verification and calibration on different pipe diameter, will get different correction coefficient, even if the same host USES the same type of different transducer, will also get different correction coefficient.

15, optional tied outside sensors:

Outer bound type sensor is to bundle sensors directly on the outer surface of the pipeline under test so as to realize the flow measurement of an installation, has has nothing to do with the pipe diameter, installation is simple, no production, no pressure loss, etc.

Technical parameters | S1 standard type | Standard M1 | Standard type L1 | High temperature type S1H | High temperature type M1H |

Suitable diameter | DN15~DN100 | DN50~DN700 | DN300~DN6000 | DN15~DN100 | DN50~DN700 |

Material is qualitative | ABS | Special high temperature material | |||

Working frequency | 1MHz | ||||

Installation method | V (N, W) method | V, and the method of Z | The Z method | V (N, W) method | V, and the method of Z |

calibration | The whole machine matching calibration | ||||

magnetic | There are | There is no | |||

Suitable temperature | 0 ℃ ~ 70 ℃ | 0 ℃ ~ 160 ℃ | |||

Protection grade | IP68 (can work immersed depth of three meters or less) | ||||

Overall dimensions | 45 * 30 * 30 | 60 * 45 * 45 | 80 x 70 x 55 | 90 x 85 x 24 | 90 * 82 * 29 |

Quality (g/on) | 75 | 250 | 650 | 94 | 150 |

Medium variety | Water, sea water, sewage, alcohol, such as various oil can conduction ultrasonic single, uniform and stable liquid. | ||||

Medium turbidity | 20000 PPM or less and the bubble content is small | ||||

Apply pipe | Carbon steel, aluminum, stainless steel, cast iron, copper, PVC, FRP uniform quality of pipes, such as the lining is allowed. | ||||

Pipe lining material | Epoxy asphalt, rubber, mortar, polypropylene, polystyrene, bakelite, teflon, etc. | ||||

Signal cable | SEYV75 - type 2 special shielded cable, single can be extended to 300 meters, wiring cable should be with metal casing to increase anti-jamming, and pay attention to the cable don't parallel with high voltage cable, as far as possible to avoid the frequency converter and other interference sources. | ||||

16, optional insert sensors:

Insert type sensor is refers to the hole on the pipeline to be tested using special tools in online punching without shutdown, so direct contact with the sensor and measured medium so as to realize the flow measurement of an installation, the sensor has solved the outer bound type sensor in measuring scale thick line to receive the signal and measurement signal attenuation problem for a long time, has not stopped production installation, maintenance free, has nothing to do with the pipe diameter, pressure loss, etc.

Pipe material is carbon steel or stainless steel can be directly welded installation, for not directly welded pipe, such as cast iron, cement, glass fiber reinforced plastic, PVC pipe should be equipped with the factory production of special pipe hoop before installation, to prevent leaking, when you place an order, please provide accurate measured pipe diameter or circumference.

Technical parameters | Standard insert type B (into) | Insert type C (inclined plug-in, very common) | Extended inserting type B (cement works) |

Suitable diameter | DN80mm above | ||

The material | Ball valve and sheath maerial: 316 l stainless steel;The ball valve base: plain carbon steel (stainless steel optional) | ||

Working frequency | 1MHz | ||

Apply pipe | Carbon steel, stainless steel, cast iron, copper, PVC, aluminum, glass fiber reinforced plastic and cement pipe pipe, such as the lining is allowed Note: 1, carbon steel, stainless steel can be directly welded (stainless steel pipe must adopt stainless steel base, please note when you place an order). 2, other pipe with pipe hoop before installation (coupling material: carbon steel, when placing order, please provide the accurate pipe diameter or circumference). | ||

installation | The Z method | ||

Suitable temperature | - 40 ℃ ~ 160 ℃ | ||

The size of hole | Ф 19 mm (with manufacturers provide dedicated openings for a installation, can be realized with no production installation) | ||

Classes. | 1.6 MPa (< 0.8 MPa pressure when installation) | ||

Protection grade | IP68 (can work immersed depth of three meters or less) | ||

The installation space | Wall to wall or 550 mm | Wall to wall or 360 mm | Wall to wall or 700 mm |

Long degrees | 186mm | 228mm | 330mm |

Medium variety | Water, sea water, sewage, alcohol, such as various oil can conduction ultrasonic single, uniform and stable liquid. | ||

Medium turbidity | 20000 PPM or less and the bubble content is small | ||

Signal cable | SEYV75 - type 2 special shielded cable, single can be extended to 300 meters, wiring cable should be with metal casing to increase anti-jamming, and pay attention to the cable don't parallel with high voltage cable, as far as possible to avoid the frequency converter and other interference sources. | ||

The 17th and selection code:

Type no. | code | The name says | |||||||

ZWS-100F | - | - | - | - | - | - | - | - | In the ultrasonic flowmeter (wei measurement and control) |

The host style | 1 | wall | |||||||

2 | explosion-proof | ||||||||

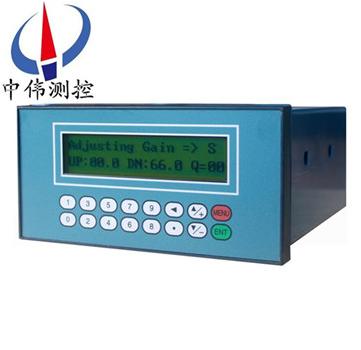

3 | Disc mounted | ||||||||

Pipe diameter | DN | DN15-DN6000mm | |||||||

Optional sensor | S1 | S1 standard type sensor (bound type) | |||||||

M1 | Standard M1 type sensor (bound type) | ||||||||

L1 | Standard type L1 sensor (bound type) | ||||||||

S1H | High temperature type sensor S1 (bound type) | ||||||||

M1H | High temperature M1 type sensor (bound type) | ||||||||

C | Insert B type sensor (plug-in) | ||||||||

G | DN15 - DN1000mm (KNN) | ||||||||

Input mode | 0 | No input | |||||||

1 | 4-20 ma input | ||||||||

2 | Pt100 platinum resistance input | ||||||||

Output way | 0 | There is no output | |||||||

1 | 4-20 ma output | ||||||||

2 | Relay output | ||||||||

3 | OCT output | ||||||||

4 | RS-232 | ||||||||

5 | RS-485 | ||||||||

Power supply | D | 220VAC | |||||||

F | 24VDC | ||||||||

Signal cable | LN | 5 m x 2 | |||||||

Example:,ZWS-100F3-200-M1-0-1-A-L5;

Explanation: the pipe diameterDN200mm,The standard standardM1Sensors, no input,4-20mAThe output,220VACPower supply, signal cable5mX 2。

18, design selection and ordering information:

1, products: specify model standard, if any, please live in wei sales hotline advisory prices, details!

2, technical support, if not specified product specifications, please put the working condition of requirements, design drawings, technical specifications, to us.

3, product orders for parameters: size (DN), nominal pressure (Mpa), temperature (℃), the connection way (flange, etc.) to the clamp.

4, offer confirmation: the company provide price list and technical standard specifications to customers to confirm, in the technical aspects to confirm before you draw up a contract.

5, quality requirements, quality standards, the supplier is responsible for the quality conditions: according to the relevant state quality standards.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.