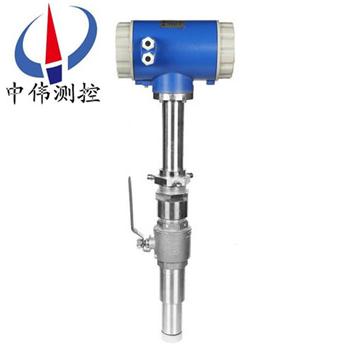

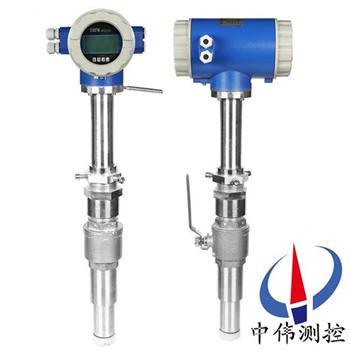

Simple plug-in electromagnetic flowmeter

Products overview:

ZW - LDEC seriesSimple plug-in electromagnetic flowmeterWhose character is: the appearance of the sensor is cylindrical structure, internal installation by the coil in a magnetic field has formed on the outer edge of the sensor launch outside magnetic field, using the installation at the end of the sensor measuring electrode, feeling the current body after cutting lines of magnetic force produces electromotive force signal, so as to achieve the goal of measuring flow rate.Through the adoption of cylindrical structure, its processing technology is simple, high detection sensitivity, is not easy to hang attachments, testing flow range (especially measurable low velocity), small installation base, pipe hole diameter of 60 mm or so, because use coarser insert stem diameter, improve the rigidity of the inserted bar at high flow velocity does not produce scratching.No moving parts, is not easy to damage, small amount of maintenance, etc.The sensor with the traditional insert a small electromagnetic flow meter installed in the rod end, measurement on the pipe, structure is more simple, more compact volume.

Second, the working principle:

ZW - LDEC seriesSimple plug-in electromagnetic flowmeter based on Faraday electromagnetic induction principle, with the sounding pipe axis and the magnetic field lines in the vertical tube wall installed on a pair of detecting electrodes, when conducting liquid along the measuring tube axis movement, conductive liquid cutting lines of magnetic force induced electric potential, the induction electric potential by two detection electrodes detection, numerical size and flow into a direct ratio, its value is: E = KBVD type:

E - induction electric potential;

K - factor related to the magnetic field distribution and the axial length;

B - magnetic induction intensity;

V - conductive liquid average flow velocity;

D - electrode gap;(the measuring tube diameter)

Sensor will be induced potential E as traffic signal, sent to the converter, amplifying, transform filter with a series of digital processing, USES dot matrix LCD display with backlight instantaneous flow and cumulative flow.Converter has 4 ~ 20 ma output, alarm output and frequency output, and is equipped with RS - 485 communication interface, and supports HART and MODBUS protocol.

Applications:

ZW - LDEC seriesSimple plug-in electromagnetic flowmeter is mainly used to measure volume flow of conducting liquid and slurry in the closed pipeline.Including acid, alkali, salt and other corrosive liquids.The products are widely used in petroleum, chemical, metallurgical, textile, food, pharmaceutical, paper making industries and environmental protection, municipal administration, water conservancy construction and other fields.

Four, the structure form:

1, the sensor:

Sensor is mainly composed of measuring tube and electrode, excitation coils, iron core, magnetic yoke and shell.

A, measuring catheter: by stainless steel tube, the lining and the connecting flange, as the carrier of measured liquid measurement working conditions on site.

B, measuring electrode: installed in the measuring tube inside wall, and the axial direction perpendicular to a pair of electrodes to measure liquid signal generation.

: c, excitation coil in a magnetic field measurement of intraductal two excitation coil.

D, iron core and magnetic yoke: the excitation coil of the magnetic field generated import liquid, and the magnetic circuit.

E, shell: instrument packaging.

2, the converter:

Is the smart secondary table, it will flow signal amplification processing, microcontroller after operation, can display flow, total amount, and can output pulse and analog current signal, used in the measurement or control of fluid flow.

3, product assembly form:

It into a shape and size in two forms.

A, a shape: mounted sensors and switches.

B, size: separation installation sensor and converter, through the connecting cable form flow metering system.

C, in order to adapt to the measurement demands of the different medium, the lining of sensor and electrode materials can have many choices.

Five, the main features:

1, corrosion resistant stainless steel material ABS mold production all probe has simple structure, strong, no moving parts, long service life:

2, reliable measurement, strong anti-interference ability;

3, small volume, light weight, small volume, convenient installation and maintenance;

4, large measuring range, the measurement is not affected by temperature, density, pressure, viscosity and conductivity change impact;

5, the pressure loss is zero;

6, can in the case of continuous flow for installation, disassembly, maintenance has brought convenience for users.

7, the general manufacturing cost and the low cost of installation, especially suitable for large and medium diameter pipe flow measurement.

Six, the technical parameters:

1, the nominal diameter: DN80 - DN2200: ZW - LDEC series;

2, flow direction, is, and net flows;

3, range: 150:1;

4, repeatability error: measurements of + / - 0.1%;

5, precision grade: : 0.2, 0.5, 1.0;

6, the temperature measured medium:

Ordinary rubber lining: - 20 ~ + 60 ℃;

High temperature rubber lining: - 20 ~ + 90 ℃;

Ptfe lining: - 30 ~ + 100 ℃;

High temperature type vinyl liner: - 30 ~ + 180 ℃;

7, rated pressure: 0.6-40 mpa;

8, measuring range, the flow measurement range convection velocity range is 0.3-15 m/s;

9, conductivity range: be flow conductivity 5 mu s/cm or more, most of the ingredients in water medium, its conductivity within 200-800 mu s/cm, all can choose electromagnetic flow;

10, output current and load resistance: 4 ~ 20 ma full isolation load resistance < 750 ohms pulse frequency 0 and 1 KHZ photoelectric isolation OCT external electrical conduction 35 v or less collector z large current of 25 ma;

11, electrode materials: molybdenum stainless just, titanium (Ti), tantalum (Ta), hartz alloy (H), platinum (Pt) or other special electrode materials;Protection grade: diving type: IP68, other type IP65;

12, power supply: 85 ~ 265 v, 45 ~ 63 hz;

13, straight pipe length: pipeline: p 5 dn, upstream or downstream 2 dn.

14, connecting method: adopt flange connection between meter and piping, flange connection size shall comply with the terms of GB9119-88;

15, working power: an external ac 220 v, 24 v dc converter, the built-in battery options;

16, riot marks: EXdllBT4;

17, environment temperature: 25 ℃ ~ + 60 ℃;

18, relative humidity: 5% ~ 95%;

19, the total power consumption: less than 20 w.

Seven, installation requirements:

1, the choice of the installation environment:

A, should as far as possible away from strong electromagnetic field devices, such as big motor, transformer, etc.

B, the installation place should not have a strong vibration, pipe fixation.The environment temperature should be changed.

C, installation environment should be easy to install and maintain.

2, installation location choice:

A, always with the current position must ensure that the pipe body.

B, and the choice of fluid flow pulse small place.That should be far away from the pumps and valves, elbow and other local resistance.

C, measuring dual phase (solid, liquid or gas, liquid) fluid, should choose the place is not easy to cause phase separation.

D, should avoid to appear negative pressure at site.

E, easy be side pipe diameter or circumference measurements, and ovality should be smaller.

3, straight pipe length:

Sensors installed pipe straight pipe upstream side length should be greater than or equal to 10 d, downstream should be not less than 5 d.D for pipe size to be tested.

4, flow control valve and regulating valve:

Flow control valves should be installed in the sensor on the upstream side of pipe to be tested, flow control valves should be installed downstream of the sensor in side.Measurement, usually flow control valves should be in the fully open position.

5, installation pedestal welding requirements are as follows:

A, the axis of the install base 63 pipe with pipe axis perpendicular to be tested.The Angle is 90 °

B, using electrode welding.Guarantee after welding flange end face parallel to the pipe axis, weld a solid, can withstand the pressure 1.6 Mpa no leakage phenomenon.

C, measured pipe hole size and install the base hole diameter.

6, installation method:

A, vertical installation: sensors should be inserted into the pipe and pipe section vertical diameter less than 5 ° Angle, suitable for measuring the pipeline vibration small cleaning medium.

B, tilted installation: its the axis of the sensor and the axis of the pipeline under test Angle 45 °, is fit for measuring the medium or big diameter and other impurity is contained in the liquid flow measurement, small resistance of the installation of water, should not be bound to hang.

C, plug-in electromagnetic flow sensor insertion point there are two ways: one is inserted into the pipe to be tested on the central axis, the second is inserted into the pipe wall for the pipe of 0.25 D.

7, the installation of sensors:

A, clean up the measured pipe installation pedestal welding slag and burr.

B, turn off the upstream flow control valves or low pressure water supply.

C, will be installed (ball valve to the base.Pay attention to the the sky cavity up ball valve, check valve to fully open, fitted to press the compression screw, nut and rubber seal installed onto the ball valve.Loosen the nut.Insert the sensor rod through the ball valve is inserted into the pipe to be tested, at the same time should pay attention to the sensor direction pointing to the antenna should work in harmony with the direction of flow.

Eight, earthing protection, must pay attention to the following:

1, sensor, converter should be separate grounding, not even on the motor, process piping, grounding resistance should be less than 10 ohms.

2, sensor measurement of tube and shell, shielded wire, converter and secondary instrument must be grounded.

3, sensors, converters, grounding on the scene, to the shield in the control room side of the secondary instrument grounding, not multiterminal grounding, lest introduced due to different potential interference.

4, sensors installed in a metal tube, the sensor can be grounding wire connected to the pipe flange according to the requirement of the factory, the formation of reliable grounding instrument ground should be an independent site, can not share other electrical equipment grounding.

Nine, install and use notice:

1, the sensor should be installed vertically, and fluid flows from bottom to top, in order to meet the solid and liquid two is in a state of mixed.The reason is that if there is solid in the medium (sand, gravel particles, etc.) are prone to precipitation.Have fish and weeds in another line of fish swimming in the pipeline, will cause the flowmeter output swing;Hang back and forth near the electrode weeds can also cause the output of the meter is not stable.Set at the entrance of upstream flow meter metal screen blocking fish and weeds into the measuring tube.

2, to prevent the negative pressure pipe set improper operation will cause negative pressure sensor inside.When closed, downstream of the valve in the flow meter at the same time, if the temperature is higher than the temperature of the fluid.Contraction after cooling, the pipe pressure is in danger of forming negative pressure.The negative pressure caused by the lining and metal vessel, cause leakage electrode.

3, near the flowmeter and negative pressure to prevent valve, open the valve on atmospheric pressure, in order to prevent to produce negative pressure in the sensor.Downstream by a vertical line, if use flow upstream of the valve to close or adjusting flow sensor, the sensor will form a negative pressure measuring tube.In order to prevent negative pressure, need to add back pressure or use downstream to adjust and close the flow valve.

4, proper maintenance space, large diameter flowmeter are often installed in instrument well, for pipe installation, wiring, inspection and maintenance convenience, need to have the appropriate space.For observation, connection and maintenance convenience, instrument installation should have a certain height from ground, in order to facilitate cleaning, installation.

Ten, selection of parameters:

For ZW - LDEC series, the design unit should according to the main technical indicators, with reference to the actual situation of the user selection.

1, the determination of suitable flow range:

If the user pipeline has been completed, can choose according to table phase for traffic and sensor calibration.

If the user is not well pipe, first of all, sensor size should be determined according to the flow range to consider is equipped with cut-off valve type and installation without a stop valve type sensor.

2, pressure and usage:

User can choose according to the requirement of the pipeline pressure sensors of pressure index, general plug-in electromagnetic for special occasions requiring small pipe pressure, suitable for large and medium-sized circulating water in the pipe, the source water and water metering.In addition, the LDC plug-in electromagnetic flowmeter with diameter of an organic whole, cheaper than electromagnetic flowmeter.

3, probe and insertion rod form:

Probe form is determined according to the situation of medium suspension, generally suspended matter how not easy disassembling often choose open, otherwise choose catheter type. Insert the pole form is for installation requirements. General screw is easy to install.

Eleven, reference flow range:

CALmm | Flow rangem3/h | CALmm | Flow rangem3/h |

Phi is 15 | 0.06 ~ 6.36 | Phi 450 | 57.23~5722.65 |

Phi 20 | 0.11~11.3 | Phi 500 | 70.65~7065.00 |

Phi is 25 | 0.18~17.66 | Phi 600 | 101.74~10173.6 |

Phi 40 | 0.45~45.22 | Phi 700 | 138.47~13847.4 |

Phi 50 | 0.71~70.65 | Phi 800 | 180.86~18086.4 |

Phi 65 | 1.19~119.4 | Phi 900 | 228.91~22890.6 |

Phi 80 | 1.81~180.86 | Phi 1000 | 406.94~40694.4 |

Phi 100 | 2.83~282.60 | Phi 1200 | 553.90~55389.6 |

Phi 150 | 6.36~635.85 | Phi 1600 | 723.46~72345.6 |

Phi 200 | 11.3~1130.4 | Phi 1800 | 915.62~91562.4 |

Phi 250 | 17.66~176.25. | Phi 2000 | 1130.4~113040.00 |

Phi 300 | 25.43~2543.40 | Phi 2200 | 1367.78~136778.4 |

Phi 350 | 34.62~3461.85 | Phi 2400 | 1627.78~162777.6 |

Phi 400 | 45.22~4521.6 | Phi 2600 | 1910.38~191037.6 |

Twelve, selection of coding:

model | CAL | (wei tt&c) material: nodular cast iron and stainless steel | ||||||||

ZW-LDEC | 150 ~ 2000 | |||||||||

Code name | Type of installation | |||||||||

Y | one-piece | |||||||||

F | Split type | |||||||||

Code name | Converter form | |||||||||

ZA | Circular converter | |||||||||

ZB | Square converter (only applicable to split type) | |||||||||

Code name | Power supply form | |||||||||

AC | (communication)220V AC 50Hz(90~245V AC 50Hz) | |||||||||

DC | (dc)24V DC (20~36V DC) | |||||||||

LD | Lithium batteries (with no signal output) | |||||||||

Code name | The output signal | |||||||||

I | 4~20mA | |||||||||

F | frequency 1KHz | |||||||||

Rs | Serial communication (485) | |||||||||

C | Control the output | |||||||||

Code name | Explosion-proof requirements | |||||||||

N | No explosion-proof | |||||||||

EX | Explosion-proof (only applicable to split type) | |||||||||

Code name | Whether or not to bring a ball valve | |||||||||

N | Without a ball valve | |||||||||

Q | With ball valve | |||||||||

Code name | The electrode material | |||||||||

316L | Stainless steel | |||||||||

Code name | Wiring (applicable to split type) | |||||||||

10 | with10Lead (standard) | |||||||||

15 | with15M lead | |||||||||

… | And so on | |||||||||

13, design selection and ordering information:

1, the measured medium: name, composition, status, electrical conductivity and electrical conductivity;

2, working temperature (℃);

3, work pressure (Mpa);

4, the pipe diameter (DN), the smallest, normal, scope of quantity (m3 / h);

5, corrosion resistance, wear resistance, whether there is a negative pressure;

6, installation requirements and the environment: a body or fission, signal output, communications, power supply;

7, installation environment: protection grade and explosion-proof requirements.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.