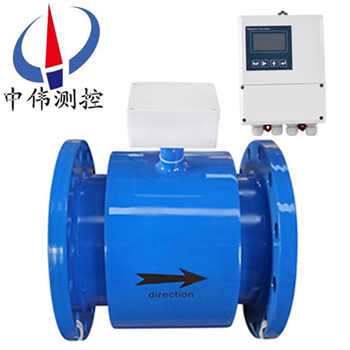

Split type electromagnetic flowmeter

I. product overview

Zw-lde series split-type electromagnetic flowmeter is an inductive meter which can measure the volume flow of conductive medium in the tube according to Faraday's law of electromagnetic induction. Wall-mounted flow converter, effective protection sensor conversion circuit, is conducive to anti-corrosion, moisture-proof, waterproof. Simple wiring and easy installation. The split electromagnetism is composed of a sensor and a transducer mounted on a measuring pipe. The transducer is mounted within 30 meters or 100 meters from the sensor, and the two are connected by a shielded cable to measure the volume flow of the conductive liquid. The main components of the sensor are: measuring tube, electrode, excitation coil, iron core and magnetic yoke. It is mainly used to measure the volume flow of conductive liquid and slurry in closed pipe.

Ii. Working principle

ZW series - LDE split type electromagnetic flowmeter based on Faraday electromagnetic induction principle, with the measuring pipe axis and the magnetic field lines in the vertical tube wall installed on a pair of detecting electrodes, when conducting liquid along the measuring tube axis movement, conductive liquid cutting lines of magnetic force induced electric potential, the induction electric potential by two detection electrodes detection, numerical size and flow into a direct ratio, its value is: E = KBVD type:

E- induction potential;

K- coefficient related to magnetic field distribution and axial length;

B- magnetic induction intensity;

V- average velocity of conductive liquid;

D- electrode spacing; (measuring pipe diameter)

The sensor takes the induced potential E as the flow signal and transmits it to the converter. After amplification, transformation and filtering, the sensor USES a series of digital processing to display the instantaneous flow and cumulative flow with a backlit point-matrix liquid crystal display. Converter has 4 ~ 20mA output, alarm output and frequency output, and rs-485 communication interface, and support HART and MODBUS protocol.

Iii. Application:

Zw-lde series split-type electromagnetic flowmeters are mainly used to measure the volume flow of conductive liquid and slurry in closed pipes. Such as water, sewage, mud, pulp, all kinds of acid, alkali, salt solution, food slurry, etc., widely used in petroleum, chemical, metallurgy, textile, food, pharmaceutical, paper and other industries and environmental protection, municipal management, water conservancy construction and other fields to measure the high temperature, high humidity, inconvenient to observe the environment.

Iv. Structure:

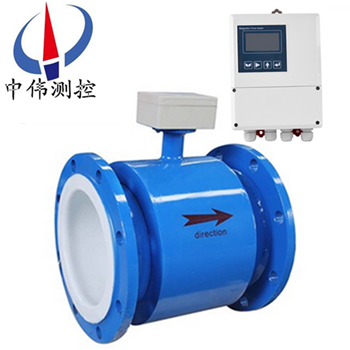

1. Sensor:

The sensor is mainly composed of a measuring conduit, a measuring electrode, an exciting coil, an iron core, a magnetic yoke and a housing.

A. Measuring catheter: it is composed of stainless steel catheter, lining and connecting flange, and it is the carrier for field working condition measurement of the measured liquid.

B. Measuring electrode: a pair of electrodes mounted on the inner wall of the measuring catheter perpendicular to the axial flow direction to generate signals from the measuring liquid.

C. Field coils: the upper and lower field coils that generate the magnetic field in the measuring tube.

D. Iron core and magnetic yoke: conduct the magnetic field generated by the excitation coil into the liquid and form a magnetic circuit.

E. Shell body: outer package of instrument.

2. Converter: it is an intelligent secondary meter, which amplifies and processes the flow signal. After the single-chip computer calculation, it can display the flow, accumulative amount, and output pulse, analog current and other signals for the measurement or control of fluid flow.

3. Product assembly form: it can be divided into two forms: one-body type and two-body type.

A. Type I: integrated installation of sensors and converters.

B. Fracturing: the sensor and converter are separated and installed, and the flow metering system is formed by connecting cables.

C. The lining and electrode materials of the sensor can be selected in a variety of ways to meet the requirements of different media measurement.

V. main features:

1. The flow measurement is not affected by the density, viscosity, temperature, pressure and conductivity of the fluid, and the sensor induced voltage signal has a linear relationship with the average flow velocity, so the measurement accuracy is high.

2. Measure the unimpeded flow in the pipe, so there is no additional pressure loss; There are no moving parts in the measuring pipe, so the sensor life is extremely long.

3. As the induced voltage signal is formed in the whole space filled with magnetic field, which is the average value of the pipeline surface, the straight pipe section required by the sensor is shorter, and the length is 5 times the diameter of the pipeline.

4. Only the inner liner and electrode of the sensor are in contact with the liquid under test. As long as the electrode and inner liner materials are selected reasonably, corrosion and wear resistance can be achieved.

5. LD converter adopts the international advanced single chip microcomputer (MCU) and surface mount technology (SMT), with reliable performance, high precision, low power consumption, stable zero point and convenient parameter setting. Click Chinese LCD to display cumulative flow, instantaneous flow, flow rate, flow percentage, etc.

6. Measuring system can measure forward flow and reverse flow. Special production process and high quality materials are adopted to ensure stable performance of the products for a long time.

7. It is applicable to measure the volume flow of conductive liquid and slurry in closed pipes, such as clean water, sewage, various acid, alkali and salt solutions, slurry, mineral pulp, paper pulp and food liquids.

Vi. Technical parameters

1. Instrument accuracy: pipe type 0.5 and 1.0; Plug-in 2.5.

2. Measuring medium: various liquids and liquid-solid two-phase fluids with conductivity greater than 5 S/cm.

3. Flow rate range: 0.2-8m /s.

4. Working pressure: 1.6MPa.

5, environmental temperature: - 40 ℃ ~ + 50 ℃.

6, medium temperature: ptfe lining 180 ℃ or less; Rubber lining material 65 ℃ or less.

7, explosion-proof marks: Exmibd Ⅱ BT4.

8. Explosion proof certificate no. : GYB01349.

9. External magnetic interference: 400A/m.

10. Shell protection: integrated type: IP65.

Split - off: sensor IP68 (5 m underwater, rubber - lined only) converter IP65.

11, the output signal: 4 ~ 20 ma DC, load resistance Ω 0 ~ 750.

12. Communication output: RS485 or CAN bus.

13. Electrical connection: M20 1.5 internal thread, phi 10 cable hole.

14. Power supply voltage: 90 ~ 220V.AC, 24 10% v.c.

15. Zui large power consumption: 10VA.

7. Main advantages and disadvantages:

Main advantages:

1. The sensor is simple in structure, and there are no moving parts in the measuring tube, nor any throttling parts that hinder fluid flow. So when the fluid flow through the flow time will not cause any additional pressure loss, is one of the flow meter running low energy consumption zui flow meter.

2. It can measure the flow rate of dirty medium, corrosive medium and suspended turbidity liquid-solid two-phase flow. This is because there is no obstructing flow component inside the instrument measuring tube, and only the measuring tube lining and electrode are in contact with the measured flow body. The material can be selected according to the nature of the measured flow body. For example, with polytrifluoroethylene or polytetrafluoroethylene as the lining, can be measured in a variety of acid, alkali, salt and other corrosive media; The wear-resistant rubber lining is especially suitable for measuring the liquid and solid two-phase flow such as slurry and cement slurry with solid particles and various suspensions such as fibrous liquid and paper pulp.

3, is a volume flow measurement instrument, in the measurement process, it is not subject to the temperature, viscosity, density and conductivity of the measured medium (in a certain range). Therefore, the electromagnetic flowmeter can be used to measure the flow of other conductive liquids only after water calibration.

4. The output is only proportional to the average velocity of the medium under test, and has nothing to do with the flow state (laminar flow or turbulent flow) under symmetrical distribution. Therefore, the range of the electromagnetic flowmeter is extremely wide, and its measurement range can reach 100:1, and some even reach 1000:1 operational flow range.

5, no mechanical inertia, responsive, can measure the instantaneous pulse flow, can also measure the flow in both directions.

6, the diameter range is very wide, from a few millimeters to a few meters, and the domestic has a diameter of up to 3m real flow calibration equipment, for the application and development of electromagnetic flowmeter laid the foundation.

At present, the main deficiencies are as follows:

1, can not be used to measure gas, steam and liquid containing a lot of gas.

2, can not be used to measure the conductivity of the low liquid medium, such as petroleum products or organic solvents and other media, the current electromagnetic flowmeter is powerless.

3. Due to the limitation of measuring tube lining materials and electrical insulation materials, electromagnetic flowmeters for common industrial use cannot be used to measure high-temperature media; If it is not specially treated, it can not be used in the measurement of low temperature medium to prevent the leakage (frosting) outside the measuring pipe from damaging the insulation.

4. The electromagnetic flowmeter is susceptible to external electromagnetic interference.